Choose the Right Fiber Laser Cutting Machine at ACCURL

ACCURL provides the best fiber laser cutting machines for all your business needs. Whether you are a first-time buyer or searching for upgrading machinery, we got you covered. Take a look at our offer and what you may find within our categories.

Learn more about Fiber Laser Cutting Machines

Evolution of Laser Cutting:

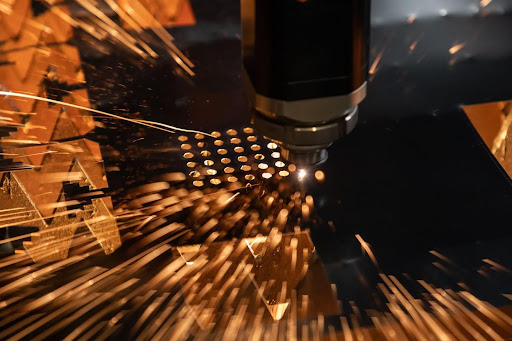

The concept of lasers traces its roots back to Albert Einstein, with the realization of the laser occurring in the 1960s. Since then, lasers have become indispensable across various technological and scientific domains. Laser cutting, specifically laser beam cutting, has emerged as a transformative technology, particularly in precision cutting of metals, wood, plastics, and more.

Advantages of Laser Cutting:

The advantages of laser cutting are manifold, making it the preferred choice for applications requiring high precision and speed. The key benefits include unparalleled precision, the ability to cut various materials, very high cutting speeds, a contactless cutting process, and exceptional versatility. State-of-the-art laser cutting systems, exemplified by the MicroStep MSF series, seamlessly combine precision, speed, and multifunctionality.

Solid-State Fiber Laser vs. CO2 Laser

In the realm of high-power lasers for laser beam cutting, two primary contenders are the CO2 laser (a gas laser) and the fiber laser (a solid-state laser). While the CO2 laser has been a stalwart in cutting technology, the fiber laser has gained prominence due to its high efficiency. Compared to CO2 lasers, fiber lasers have significantly lower operating and maintenance costs. They match established lasers in precision across different material thicknesses, making them an attractive alternative, especially considering their cost-effectiveness.

CO2 Laser

Belonging to the group of gas lasers, CO2 lasers, or carbon dioxide lasers, are known for their excellent cutting quality. Widely used for metallic and non-metallic materials, including wood, textiles, plastics, foils, acrylic, glass, paper, and leather, CO2 lasers excel in processing thicker stainless steel sheets. However, their efficiency is marked by relatively high operating and maintenance costs, standing at around 10 percent.

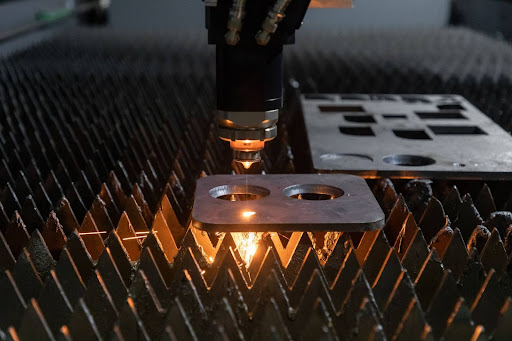

Fiber Laser

The fiber laser emerges as a cost-effective and efficient alternative. With lower operating costs and a longer service life of wear parts, fiber lasers capitalize on a beam wavelength ten times shorter than CO2 lasers. This characteristic makes them suitable for cutting challenging materials, especially non-ferrous metals. Despite the need for a variable focus diameter for higher material thicknesses, the fiber laser’s efficiency, with a socket efficiency of about 30 percent, positions it as a compelling choice.

Nd:YAG Laser

Neodymium-doped yttrium-aluminum-garnet (Nd:YAG) lasers, another category of solid-state lasers, are notable for engraving, welding, and micro-drilling. While less common in laser cutting, Nd:YAG lasers process metals, coated metals, and plastics. However, they face challenges such as higher wearing of pump diodes and a shorter lifetime for the neodymium-doped YAG crystal compared to fiber lasers.

Laser Components

The intricate functioning of a laser involves three fundamental parts: the energy source (or pump), the laser medium, and the resonator. The energy source pumps energy into the system, creating a population inversion. This process requires sufficient energy transfer into the laser medium to achieve population inversion. The resonator, comprising two curved mirrors, reflects radiation back and forth, with part of the radiation escaping as a focused laser beam.

Discover our Fiber Laser Cutting Machines

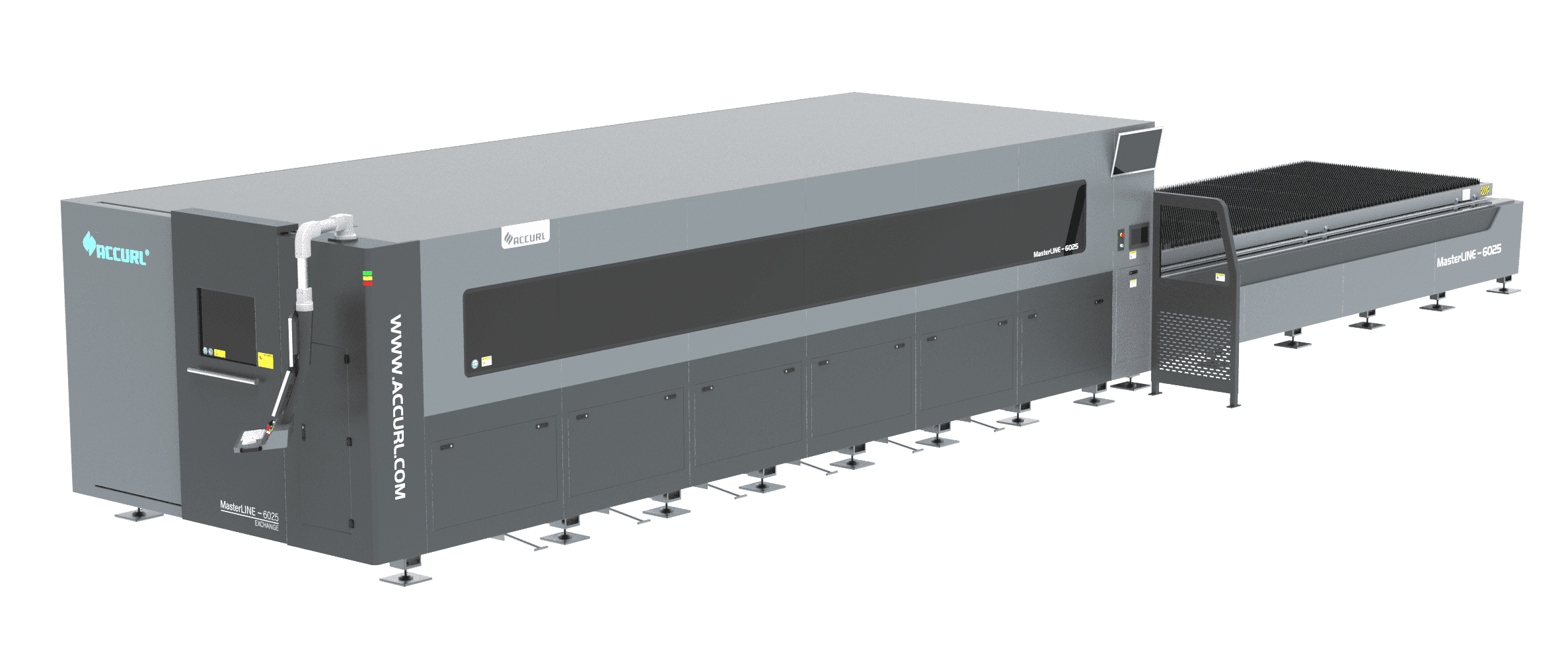

Fiber Laser Cutting Machine MasterLINE

Features:

- Revolutionary BLT421 cutting head design

- Excellent cut quality, low process time, easy maintenance

- Smooth cutting edges with minimal burrs

- Brand new optical solutions for closed-loop auto-focusing

- LED operating status display and App monitoring

Advantages:

- High-cutting edge quality with stable and precise operation

- Efficient, slag-free cutting with effective cooling mechanisms

Applications:

- Metal Fabrication: Precision cutting for metal sheets.

- Manufacturing: Efficient processing of components.

- Automotive: Right-angled cutting edges for components.

- General Engineering: Versatile cutting for various materials.

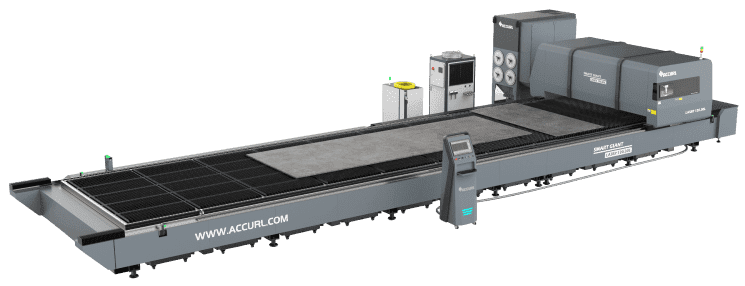

Fiber Laser Cutting Machine Smart Cube

Features:

- Compact design

- Handheld laser welding technology

- High precision for efficient cutting

- User-friendly interface

- Streamlined design for easy maintenance

Advantages:

- Versatile applications

- Efficient and controlled welding

- Smart control system

- Quick setup for repairs

Applications:

- Metal fabrication

- Construction and automotive

- Maintenance and repair

What Makes Our Fiber Laser Cutting Machines Different?

At ACCURL, we provide the best fiber laser cutting machines for all the metalworking needs of your business. It doesn’t matter what your primary goal or current focus is; whether it is more efficient when it comes to cutting or perhaps a smoother welding process, we have the perfect solution for you.

Efficiency and Productivity

Our fiber laser metal cutting machines can help achieve small to large-scale business needs. Our machines are easy to operate and reliable, ensuring that you’re able to improve the different aspects of your business for a better employee and customer experience.

Unmatched User Experience

We’ve designed our fiber laser metal cutting machines to provide a seamless experience; thanks to automatized and intuitive processes. Start the production process within a few steps at any time.

Embrace Automation

Our fiber laser cutting machines can help you streamline your production and improve your efficiency without compromising your quality. Seamlessly integrate our machines with your current systems for better compatibility.

Reduce Costs

Embracing our top-quality CNC fiber laser cutting machine may allow you to improve your business in different ways. Not only will you be able to handle a wide variety of materials and thicknesses, but you will also be able to rely on machines that utilize less power and require less effort and investment when it comes to maintenance. Our machines are reliable and durable, ensuring several years of useful life.

Why Choose ACCURL?

Whether you want a small fiber laser cutting machine or would like to find a regular-sized fiber laser cutting machine for sale, ACCURL has got you covered. Take a look at why people prefer our machines.Versatility

Our machines can be utilized for a wide range of applications. You can easily modify the automation modules to ensure they go in accordance with your metalworking process.

30+ Years of Experience

We’ve over three decades of experience, improving our service with each year that passes. We have successfully installed 22,000+ machines to date and tons of people worldwide rely on our machinery.

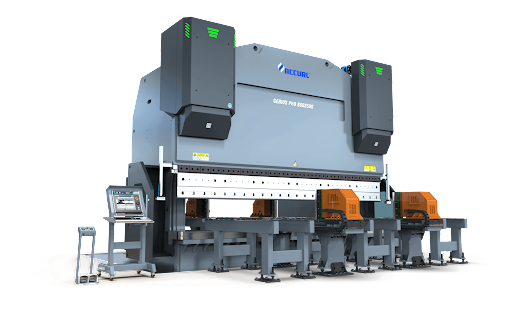

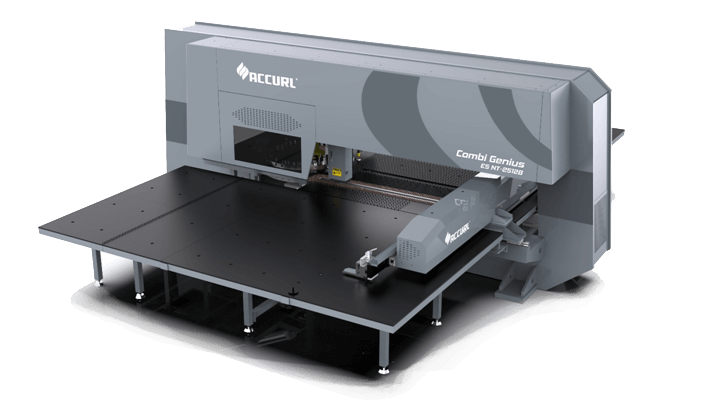

Our Machines

Complete Range of Fiber Laser Cutting Machinery

Complete Range of Fiber Laser Cutting Machinery

Get to Know More of ACCURL

Our decades of experience and thousands of clients worldwide can avail the quality of our services. If you have any questions or would like to purchase a fiber laser cutting machine from us, be sure to contact us.