Home / Machines / Bending Machines / Robotic Solutions / Bending Robotic For Press Brake

Robotic Press Brake Solutions: Redefining Precision Bending

Unlock the future of metalworking precision with ACCURL – your gateway to cutting-edge robotic press brake solutions. As industry leaders, we set new benchmarks with our cutting-edge robotic bending machines, which provide a flawless fusion of efficiency, technology, and unrivaled precision.

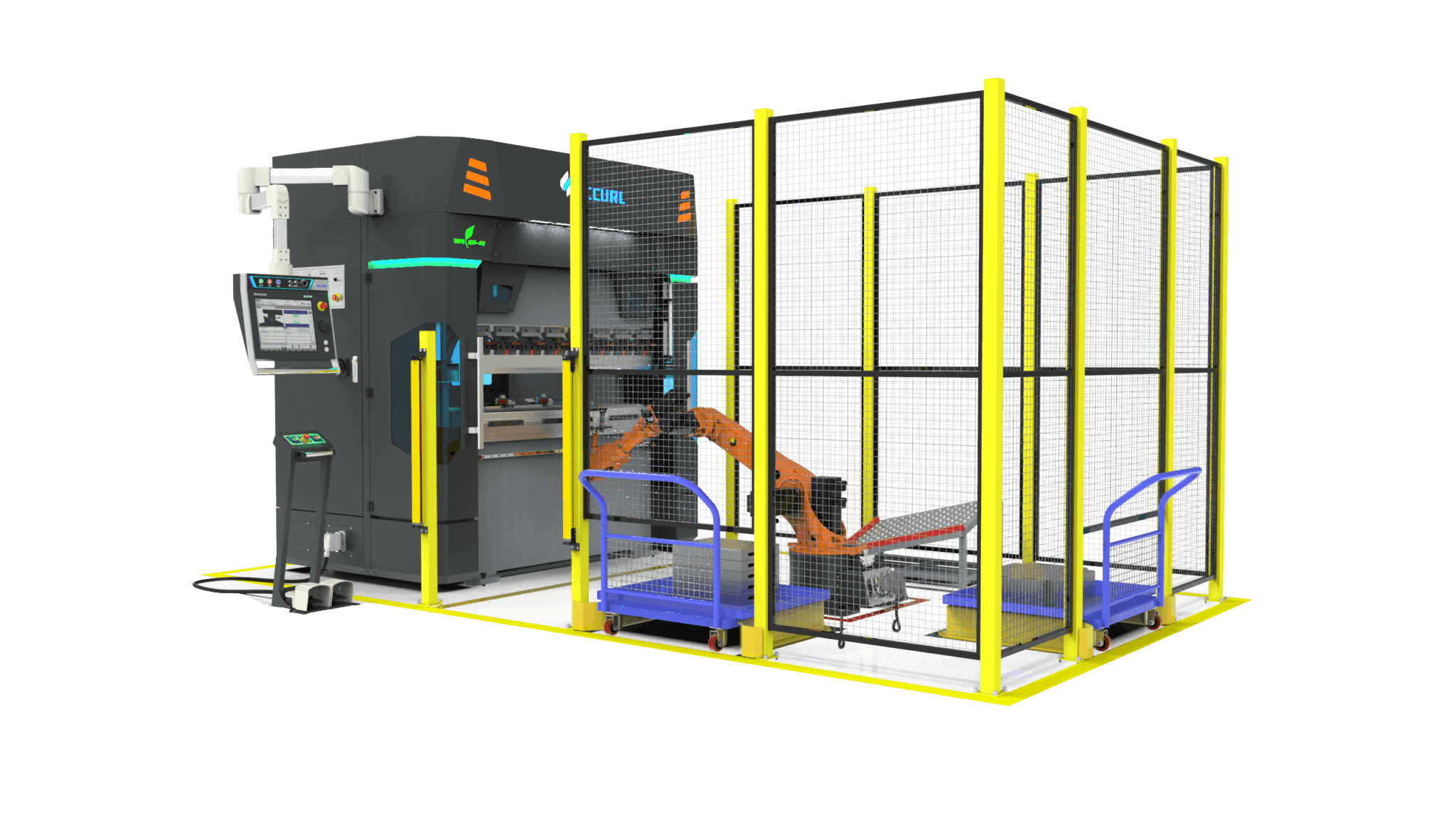

Introducing the Robotic Bending Cell

Robotic Press Brake: Unmatched Precision

Offering robotic press brake systems that raise the bar for precise bending is something we at ACCURL are proud to provide. For a variety of uses, our robotic press brake machines are built to provide accuracy, effectiveness, and dependability.

Robotic Press Brake Bending

Our automated robotic press brake bending solutions use cutting-edge technology in conjunction with automation to produce bends that are exact and reliable. The incorporation of robotic devices improves the bending procedure, guaranteeing superior outcomes while diminishing manual labor.

Robotic Tube Bender

The robotic tube benders from ACCURL are designed with precision and adaptability in mind. Our robotic tube bender is a dependable solution for tube bending applications, capable of handling tasks involving both basic and complicated tube geometries with ease.

The ACCURL Advantage as a Robotic Press Brake Supplier

ACCURL is a robotic press brake provider that you have selected because of its dedication to quality, innovation, and client satisfaction. Here is why businesses looking for robotic press brake solutions use ACCURL:

Comprehensive Robotic Bending Machines

ACCURL is a leading robotic press brake company offering a diverse range of robotic bending machines. Our machines meet a wide range of industry demands, from small-scale workshop solutions that are compact to sophisticated, large-scale production systems.

Tailored Robotic Bending Solutions

We are aware that every production procedure is different. As a provider of robotic press brakes, ACCURL adopts a personalized strategy, adjusting products to meet your unique needs. In order to guarantee the smooth integration of robotic bending machines into their production, our staff works closely with clients.

Connections:

- Loader from a precentred pack.

- Loader from a Cartesian feeder in masked time.

- Cartesian feeder with controlled axes.

- Feeder/unloader for connection in line.

- Unloader.

- Carousel unloader.

- Roller-surface unloader for pallets.

- Roller-surface unloader for pallets and crates.

- Un-intrusive machine integration with sensors to back gauge fingers and bending beam which follow the programmed sequence of the Accurl press brake

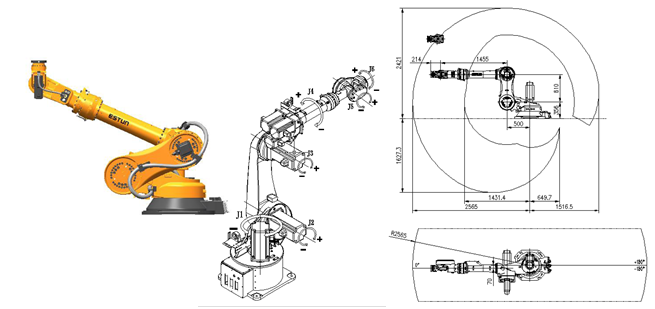

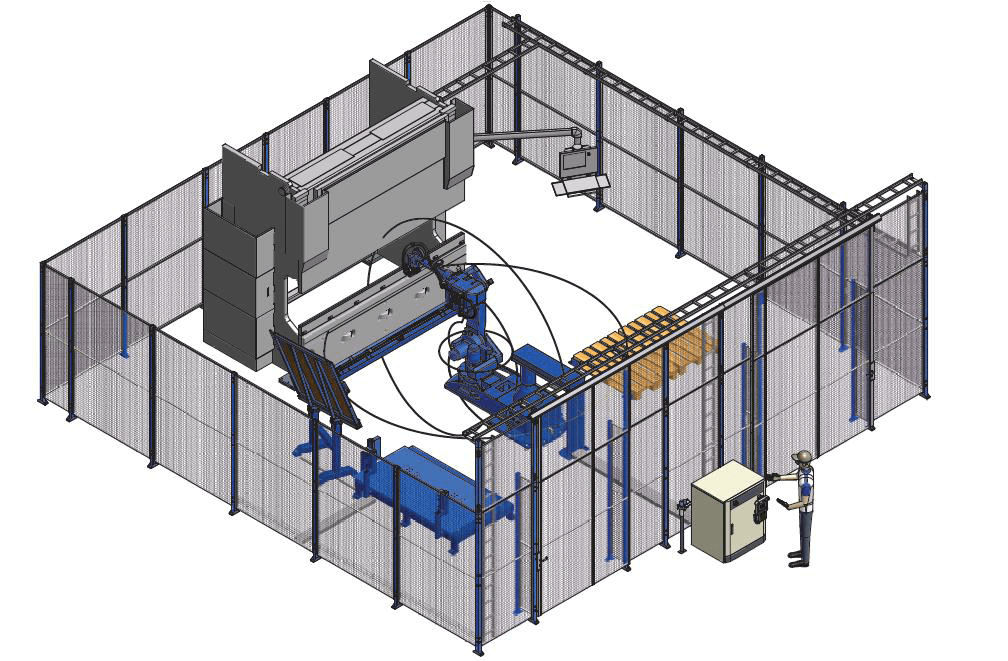

| 1 | Press brake |

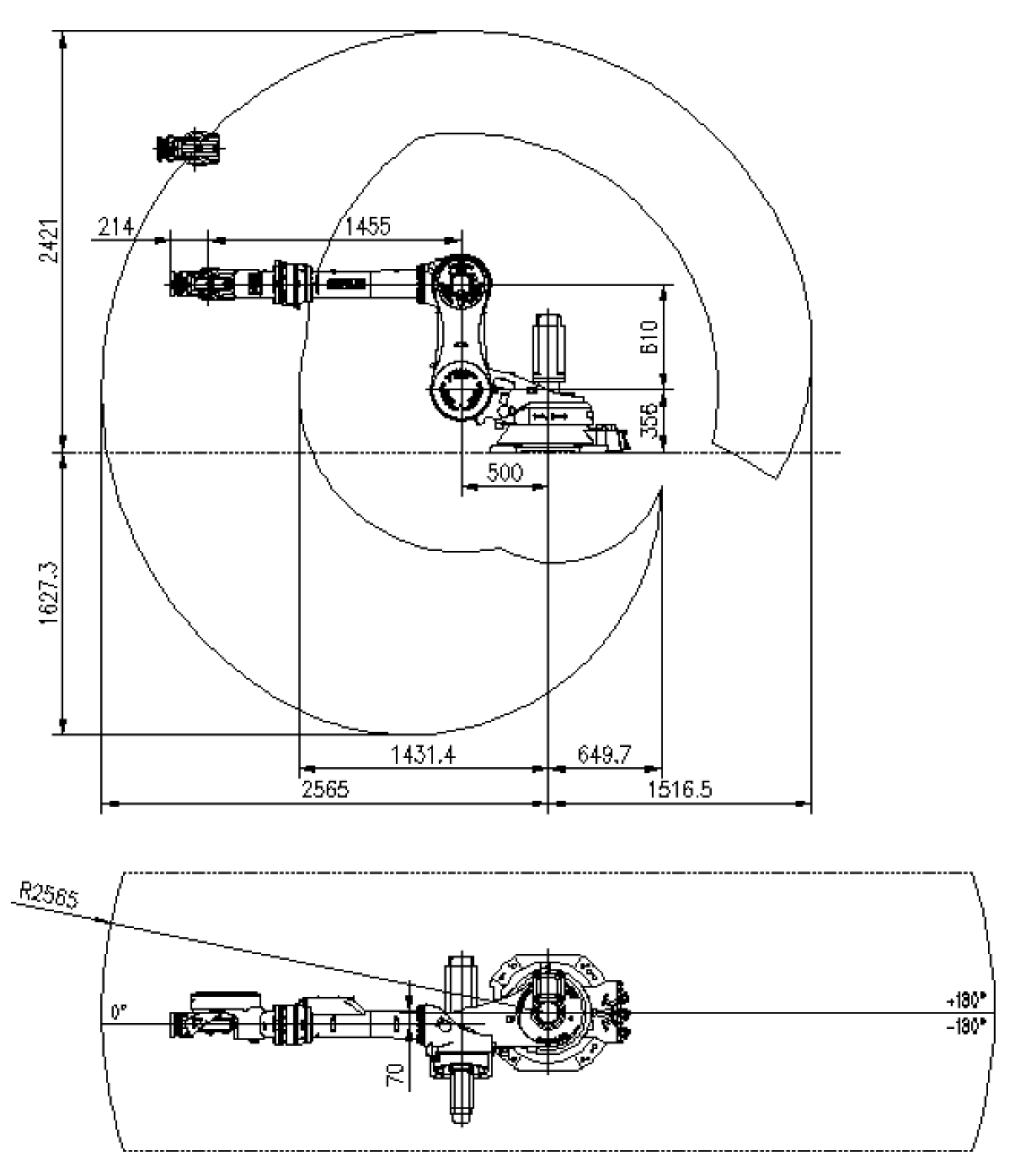

| 2 | 5-axis Robot |

| 3 | Pneumatic gripper |

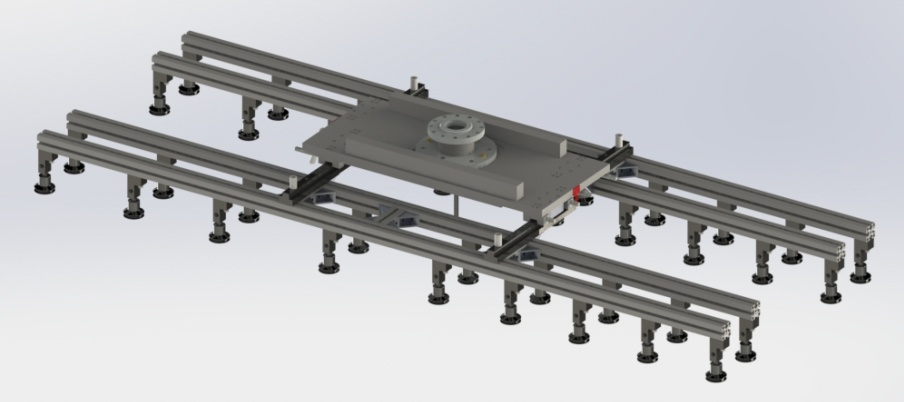

| 4 | Moving axis |

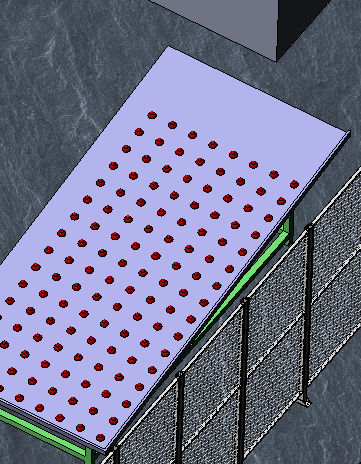

| 5 | Loading pallet |

| 6 | Centering table |

| 7 | Turn-over table |

| 8 | Stacking table |

| 9 | Electrical system |

| 10 | Safety fence |

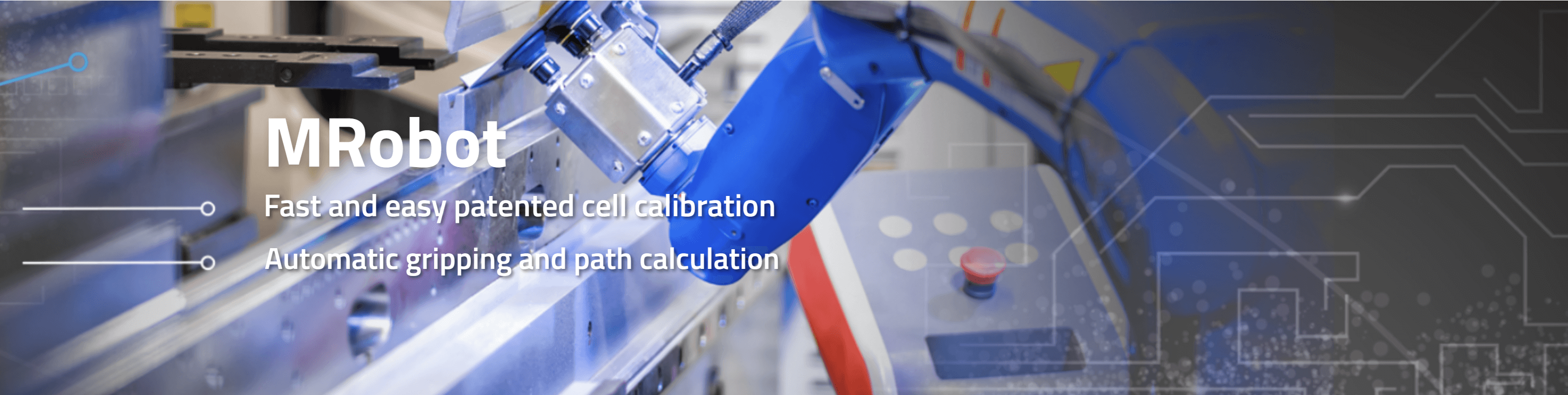

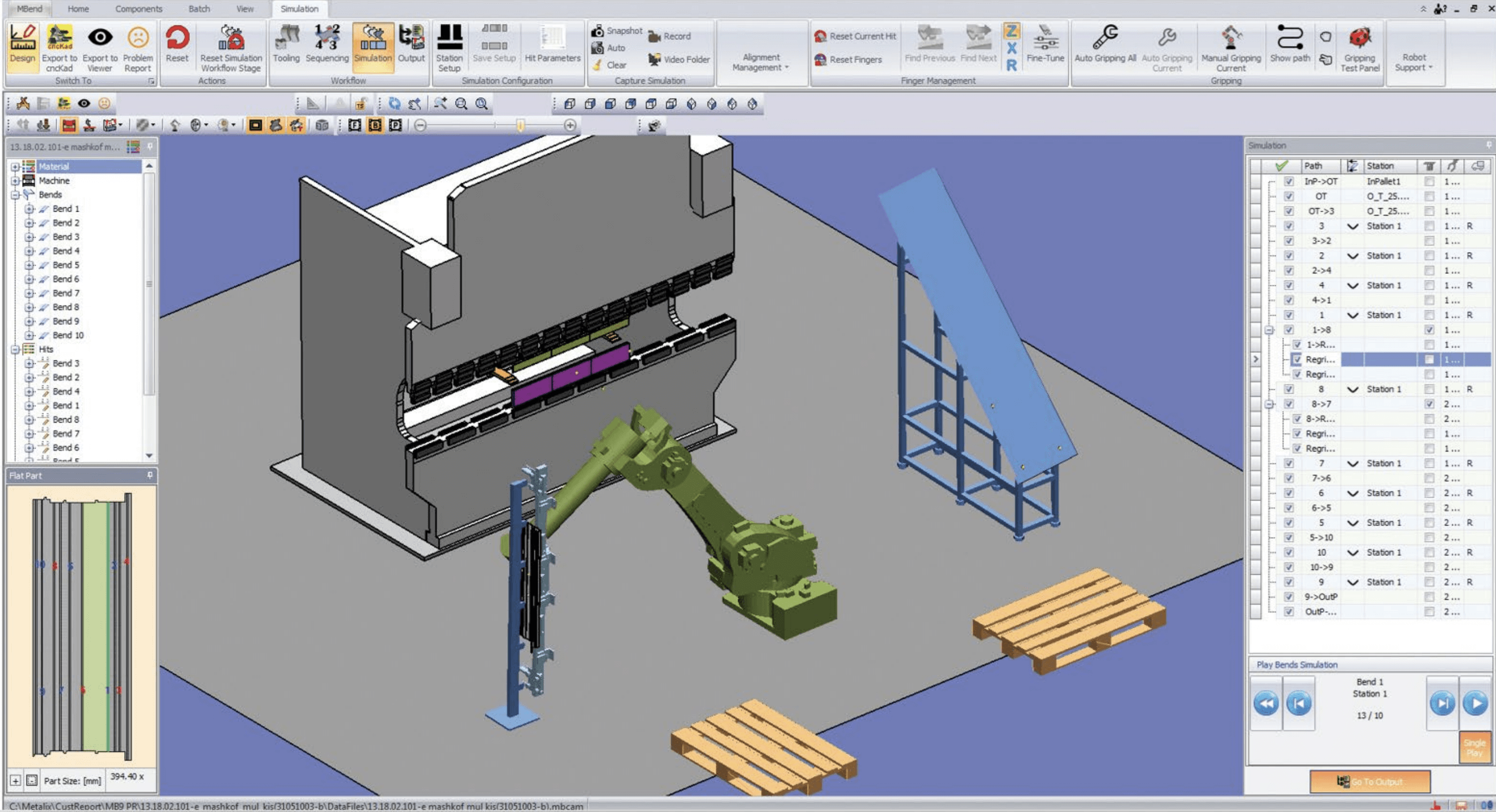

OFF-LINE FOR ROBOTIZED BENDING CELLS MRobot

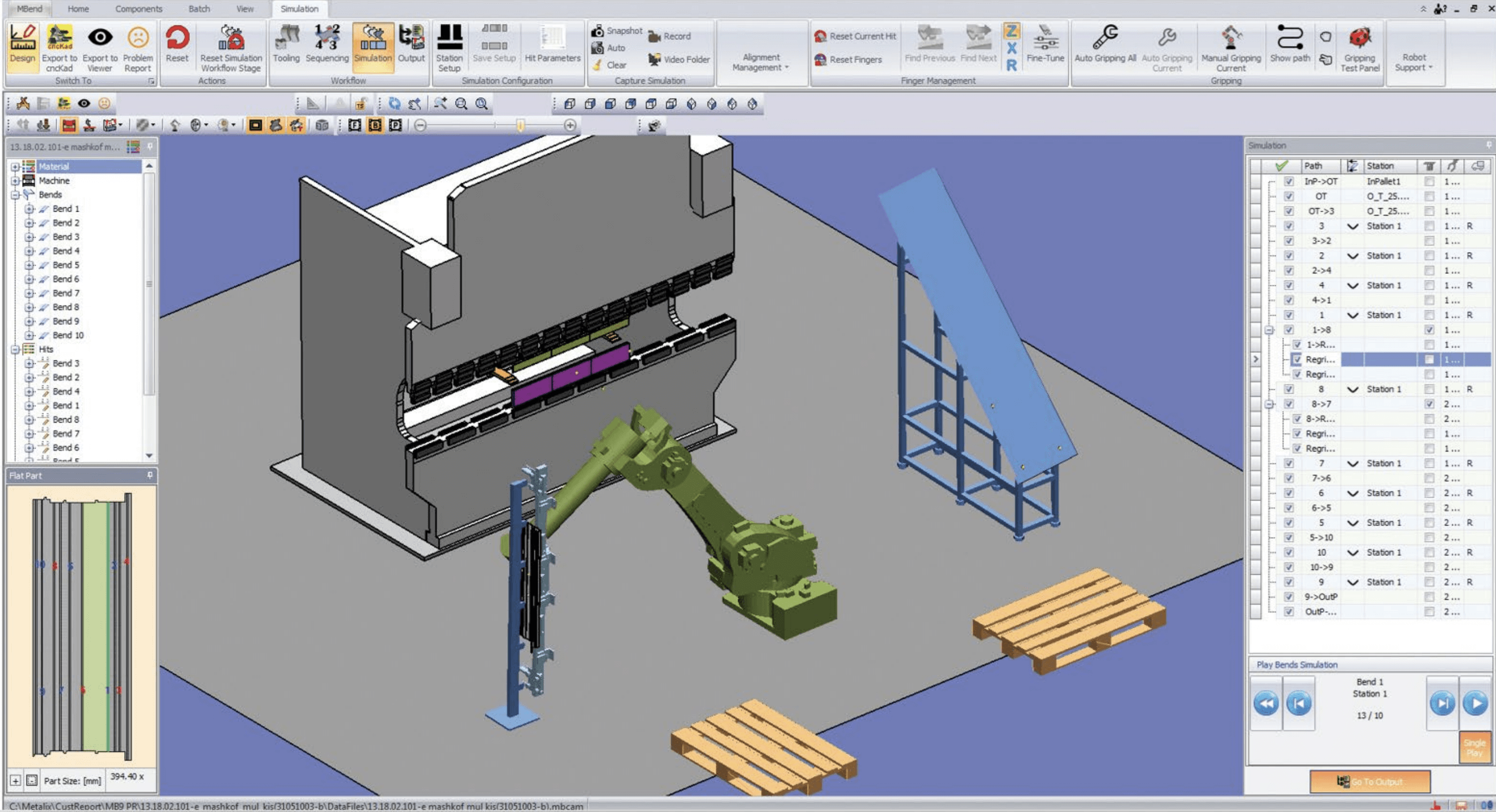

MRobot is an application for off-line programming of robotized bending cells. It enables automatic and interactive robotic solutions for bending parts, simulation to ensure a collision-free solution, and the generation of efficient programs for both the robot and the press brake. MRobot also includes a module for easy cell calibration.

Off-line programming of robotized bending cells.

Consequently, here are the main steps covered during this procedure:

- Fully automatic gripping and path calculations

- Interactive gripping with graphical feedback

- Manual path adjustments using control points

- Support for grippers with vacuum/clamp combinations

- Support for cells with rails

- Powerful yet easy to define stacking on the out-pallet

- Generation of NC code for both machine and robot

- Generation of NC code that guarantees coordinated interaction between robot and brake for smooth production

- Fast and easy cell calibration ( we provide a patented procedure)

As an extension to the MBend software, these robots can interface with most press brakes, allowing great flexibility in cell management and choice of elements.

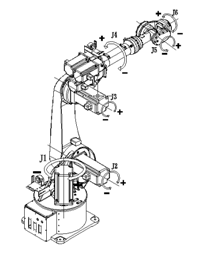

BENDING ROBOT-ER30

The ACCURL Robotic bending cell system can be equipped with different types of loading and unloading connections,depending on the client’s production requirements.

THE PROTAGONIST OF AUTOMATION

OFF-LINE FOR ROBOTIZED BENDING CELLS MRobot

Off-line programming of robotized bending cells.

Consequently, here are the main steps covered during this procedure:

- Fully automatic gripping and path calculations

- Interactive gripping with graphical feedback

- Manual path adjustments using control points

- Support for grippers with vacuum/clamp combinations

- Support for cells with rails

- Powerful yet easy to define stacking on the out-pallet

- Generation of NC code for both machine and robot

- Generation of NC code that guarantees coordinated interaction between robot and brake for smooth production

- Fast and easy cell calibration ( we provide a patented procedure)

BENDING ROBOT-ER30

THE PROTAGONIST OF AUTOMATION:

ACCURL's Robotic Bending Machines in Action

Robotic Press Brake in Precision Bending

See how the robotic press brake from ACCURL accomplishes precision bending with unmatched accuracy. With their cutting-edge features, our robotic bending machines guarantee flawless, reliable results with each bend.

Robotic Tube Bending Excellence

Discover the adaptability of ACCURL’s robotic tube bender as it performs tube bending operations with ease. With accuracy and efficiency, our robotic tube bender can create intricate forms or simple bends.

GRIPPER FOR ROBOT-ER30:

Choosing ACCURL for Your Robotic Press Brake Needs

Why partner with ACCURL for your robotic press brake requirements? Here are compelling reasons to choose us as your trusted robotic press brake company:

Expertise in Robotic Press Brake Bending

ACCURL brings a wealth of expertise in robotic press brake bending. Through constant innovation, our team of engineers and technicians is committed to expanding the realm of precise bending possibilities.

Unparalleled Support

ACCURL, as your committed provider of robotic press brakes, offers unmatched assistance for the duration of your machine’s life. We are dedicated to making sure you succeed, from installation and training to maintenance and updates.

Frequently Asked Questions (FAQs) About Robotic Press Brake Solutions

What is a robotic press brake?

A robotic press brake is a cutting-edge bending solution that uses robotic automation to streamline the bending process and produce accurate, reliable bends with less manual work.

Is it possible for a robotic press brake to bend tubes?

Indeed, ACCURL’s robotic press brake is adaptable and made to perform a variety of tube bending operations. It can accommodate a broad range of tube geometries, from straightforward bends to intricate designs.

What sets ACCURL apart as a robotic press brake supplier?

ACCURL is distinguished by its dedication to innovation, quality, and client satisfaction. We are a dependable industry partner because we provide customized robotic bending solutions, a wide variety of equipment, and committed support.

In robotic press brake bending, how can ACCURL guarantee accuracy and precision?

The sophisticated features of ACCURL’s robotic press brake systems guarantee accuracy and precision at every turn. Our machines are made to produce reliable and superior results, whether they are used for interactive gripping with graphical feedback or automated gripping and route computations. Safety measures like a 4-level safety protection raster enhance a safe workplace.

What sort of assistance is offered by ACCURL following the installation of a robotic press brake?

ACCURL pledges to offer unmatched assistance for the duration of your robotic press brake’s life. We offer installation help, thorough training for staff members and operators, routine maintenance, and access to new developments and advancements. Our goal is to make sure that your metalworking operations remain profitable and effective.

Embark on a New Era of Precision Bending with ACCURL’s Robotic Press Brake Solutions

ACCURL’s robotic press brake solutions redefine the landscape of precision bending. We have the know-how and equipment to match your demands, whether you need robotic tube bending or robotic press brake bending. Choose ACCURL as your robotic press brake company and embark on a journey of efficiency, accuracy, and innovation in metalworking.

Contact us today to explore the possibilities of robotic bending solutions tailored to your unique requirements.