Home / Machines / Tube Laser Cutting / TubeLINE BK Series

The Fully-Automatic Solution that Guarantees Maximum Productivity

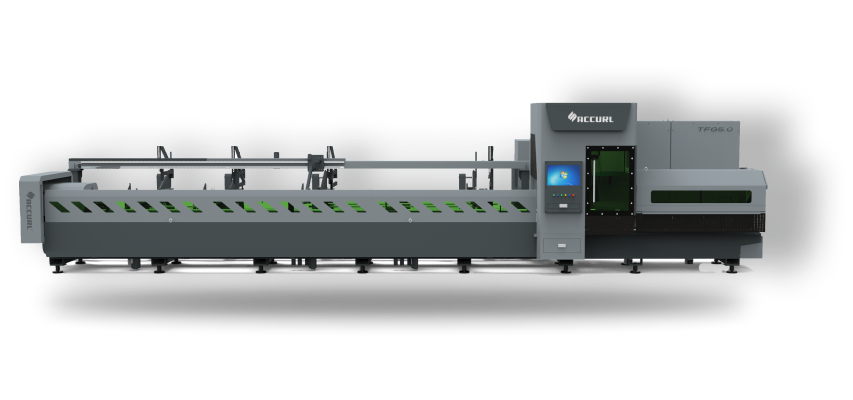

Introducing the TubeLINE BK Series

Tube ∅ Range min. 12 mm – max. 200 mm),

CD cutting mode,

Fiber laser Cutting

Laser power 2kW – 4kW IPG /MAX Photonics

CD cutting mode,

Fiber laser Cutting

Laser power 2kW – 4kW IPG /MAX Photonics

The winning solution for cutting your tubes.:

ACCURL TubeLINE BK Series is a compact and efficient tube cutting solution with advanced technical features for optimal performance.It offers versatility, ease of use,& best-in-class engineering for processing various tube shapes. Ideal for frequent production changeovers and adapting to different materials. Invest in TubeLINE for a profitable cutting solution

Optimize Tube Cutting with Advanced Technology and Versatility:

TubeLINE BK Series offers the most advanced technical solutions for efficient production changeovers and material adaptability in 2D tube cutting, boasting best-in-class engineering, user-friendly operation, and versatility in a compact footprint. Optimize your investment with this comprehensive solution for light to medium thickness tubes.

WHY ACCURL TubeLINE ? :

- The right tube laser

- Innovative features such as bevel cutting

- Comprehensive technology and cutting data

- Ergonomic machine concepts

Our functional features and expertise support tubes and profiles through every stage of the machine. Each component is optimized for maximum results, delivering real benefits at every step.

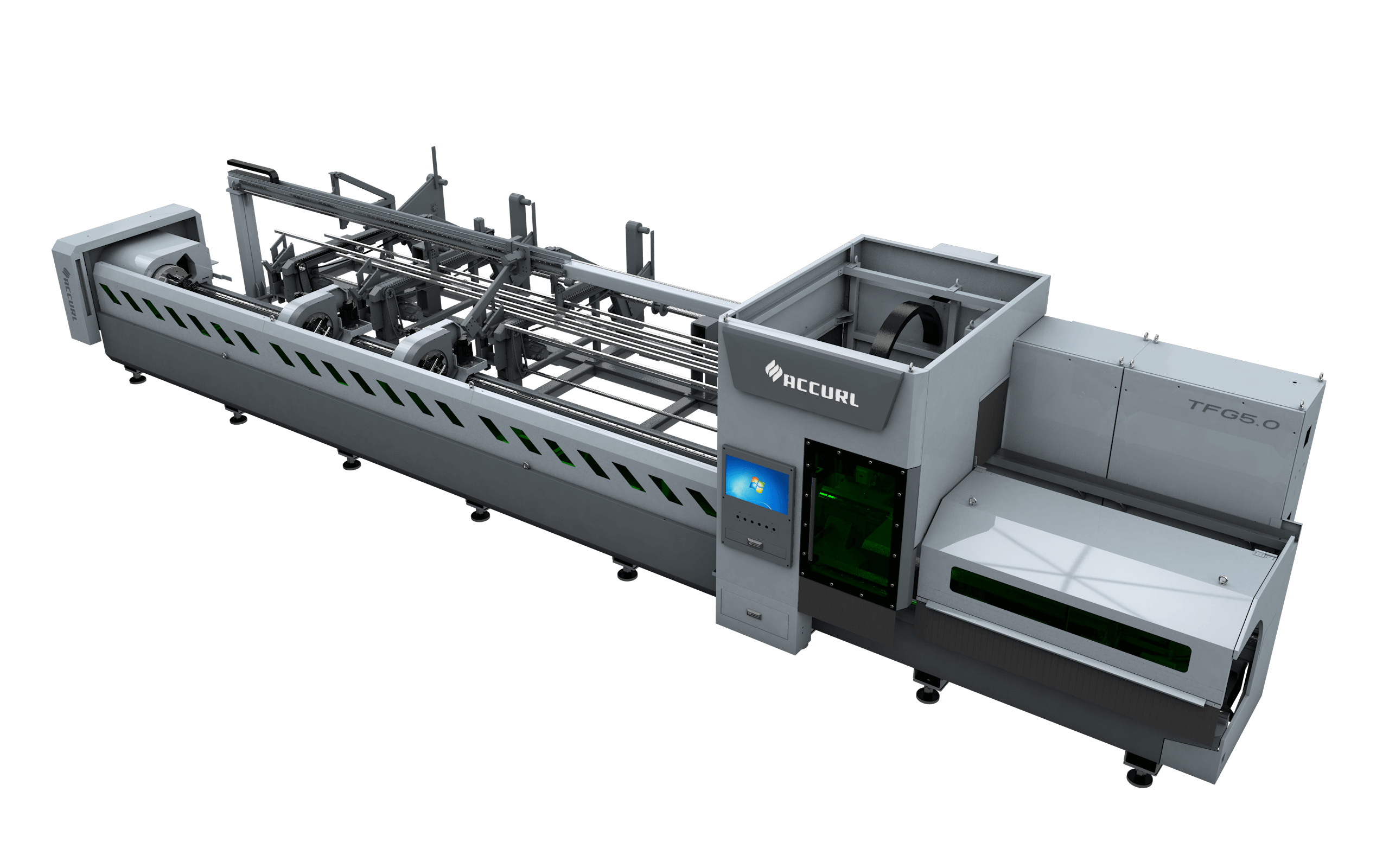

Perfectly equipped for Fast and flexible tube laser cutting:

Accelerate the tube laser cutting of tubes and profiles with the TubeLINE BK Series. Tube laser cutting with our high-end tube laser boosts the quality and performance in your production through:

- Highest precision

- Ease of use

- Fully automatic setup of all profiles, including open and elliptical tubes

Seamless accessibility:

Our innovative design ensures that every aspect of the machine, from setup and operation to the final part retrieval, embodies the concept of open accessibility.

Exceptional speed and precision:

With a robust machine frame and precision-engineered guide systems, we deliver both rapid processing and unparalleled quality in the end product.

Effortless CNC Control Panel:

ACCURL FSCUT5000 HMI revolutionizes task completion on the tube laser cutting machine. Its user-friendly interface, featuring a spacious touch screen display, makes mastering machine functions an intuitive experience, allowing you to effortlessly operate the machine with your fingertips.

Advanced Clamping (Chuck)Solution:

Incorporating L- , I Beam & U profiles in your production line?

Accurl adaptive chucks system is tailored for your needs, ensuring swift and precise processing of open profiles with utmost efficiency.

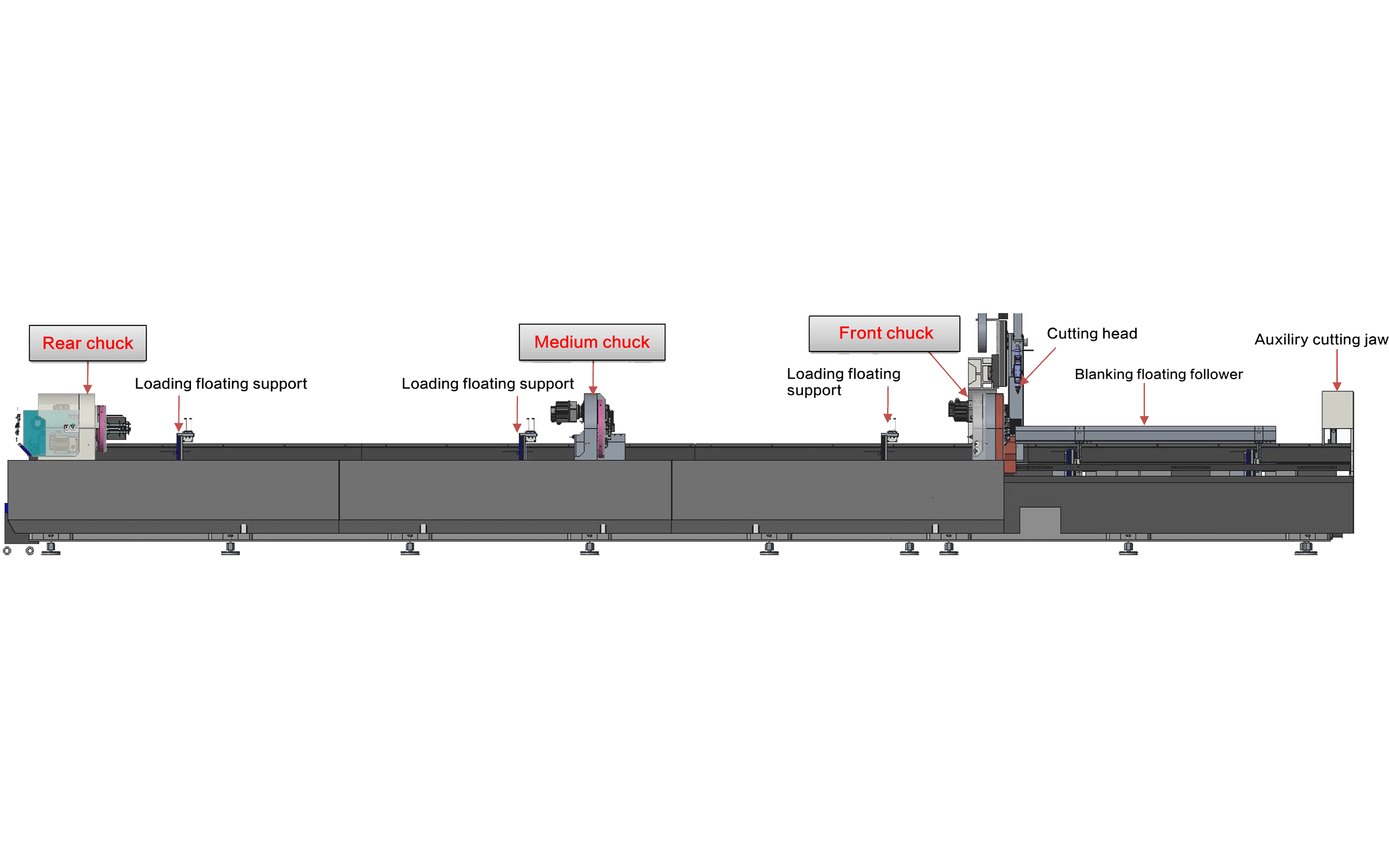

CHUCKS AND CLAWS:

Two high quality rotate chuck move with synchronous rotation, which ensure tube holding more steady . It reduce tube vibration to minimum, with solid guarantee for high accuracy in complicate tube figure.Suitable for cutting tube with diameter range from Ø20mm to Ø520mm.

DIGITAL CONTROLLING

PNEUMATIC CHUNKS:

Cut Conventional Tubes,Profiles and Special-shaped Tubes

- From front-end material loader and unloader, to servo-controlled and synchronized material supports, this semi-automated tube and profile laser is ready for your one-off structural parts or production demand.

- The TubeLINE Machine’s optional with 3 chuck design allows for ZERO tailing with optimal finished part support, and long finished part handling.

Users can load standard-sized tube and enjoy batch production with little manual intervention. for round, square,

rectangular tube, as well as angle, channel and H-shaped steel are loaded easily. and the tube to be cut is

conveyed to check-waiting area for length measuring and cut sequencing

ADVANTAGE:

– Easy tube loading for batch production. – Max. linear weight 23Kg/m – All Automatic Settings – Bundle and single bar loading – Three unloading positions – Loading size range: p16-150mm, square pipe 16-150mm. – Quick loading times: <60s first load, <20s subsequent.

ACCURL FSCUT 5000

Tube Laser Cutting CNC Controller

The FSCUT5000 series is EtherCAT bus system specially designed for fiber laser tube cutting machine. FSCUT5000A applied to 3-chuck delivering structure, FSCUT5000B applied to 2-chuck structure, work with TubesT 3D nesting software, it will achieve most efficiency and minimum waste.

Zero-tail Cutting

Save material and improve productivity

Bevel Cutting

Matched with drawing generated by nesting software to cut

3-Chuck Cutting

3-chuck full range, improve accuracy by preventing tube shaking

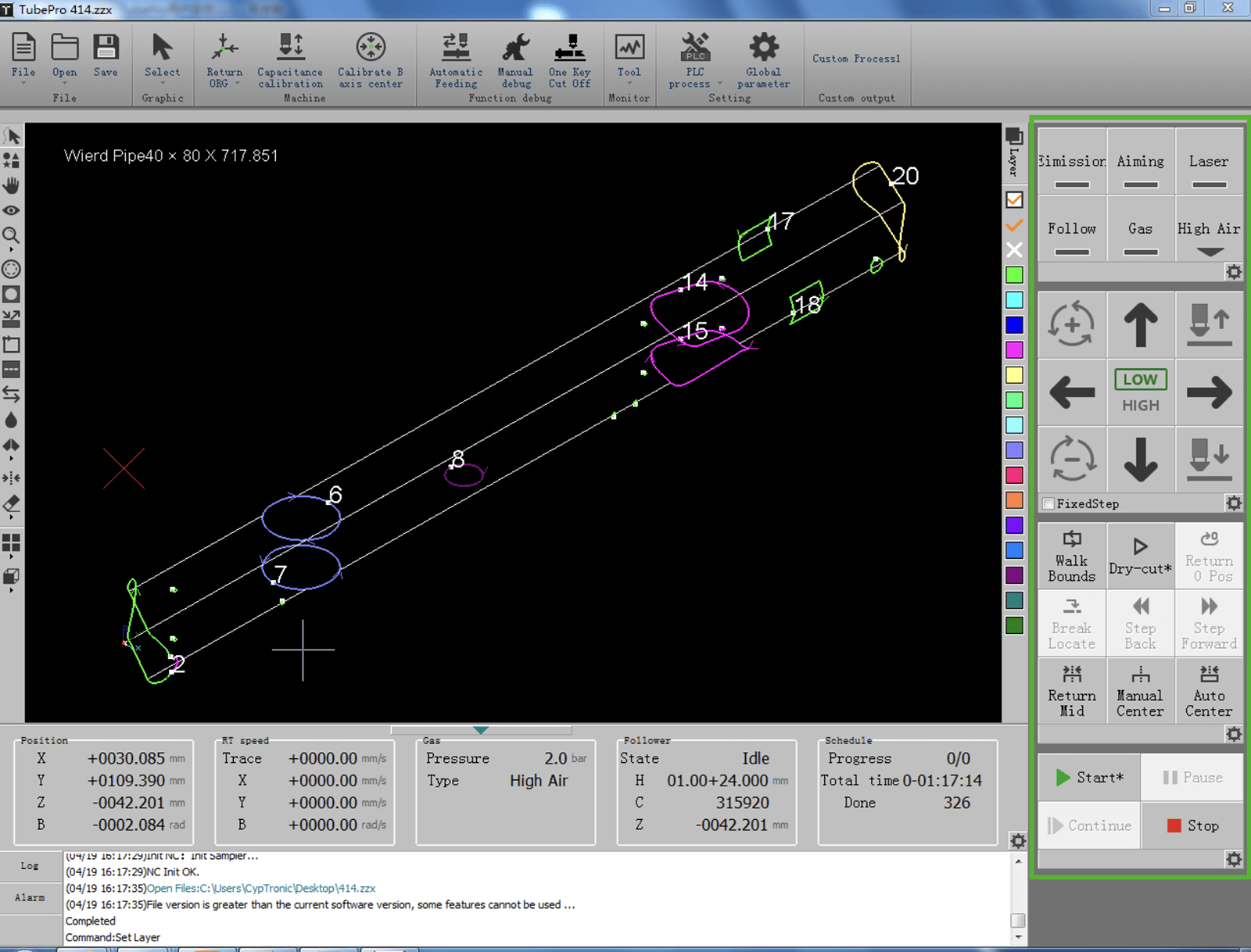

TubePro Nesting software

Tube & Profile Cutting Software

The TubePro designed for professional tube cutting, supports production of tube and profile of various shape. It works with TubesT nesting software seamlessly to realize technique setting, advanced toolpath generation and nesting for standard and special production need.

Auto Find Tube Center in Production

TubePro can locate and offset tube deviation from chuck rotation center in production to guarantee a high cutting precision

Workpiece and Floating Coordinates

Workpiece mode adopts zero point of a fixed position used in production of processed tube, for example, piercing holes on cutted tube. Floating mode takes zero point where it stands and allows user to start production freely.

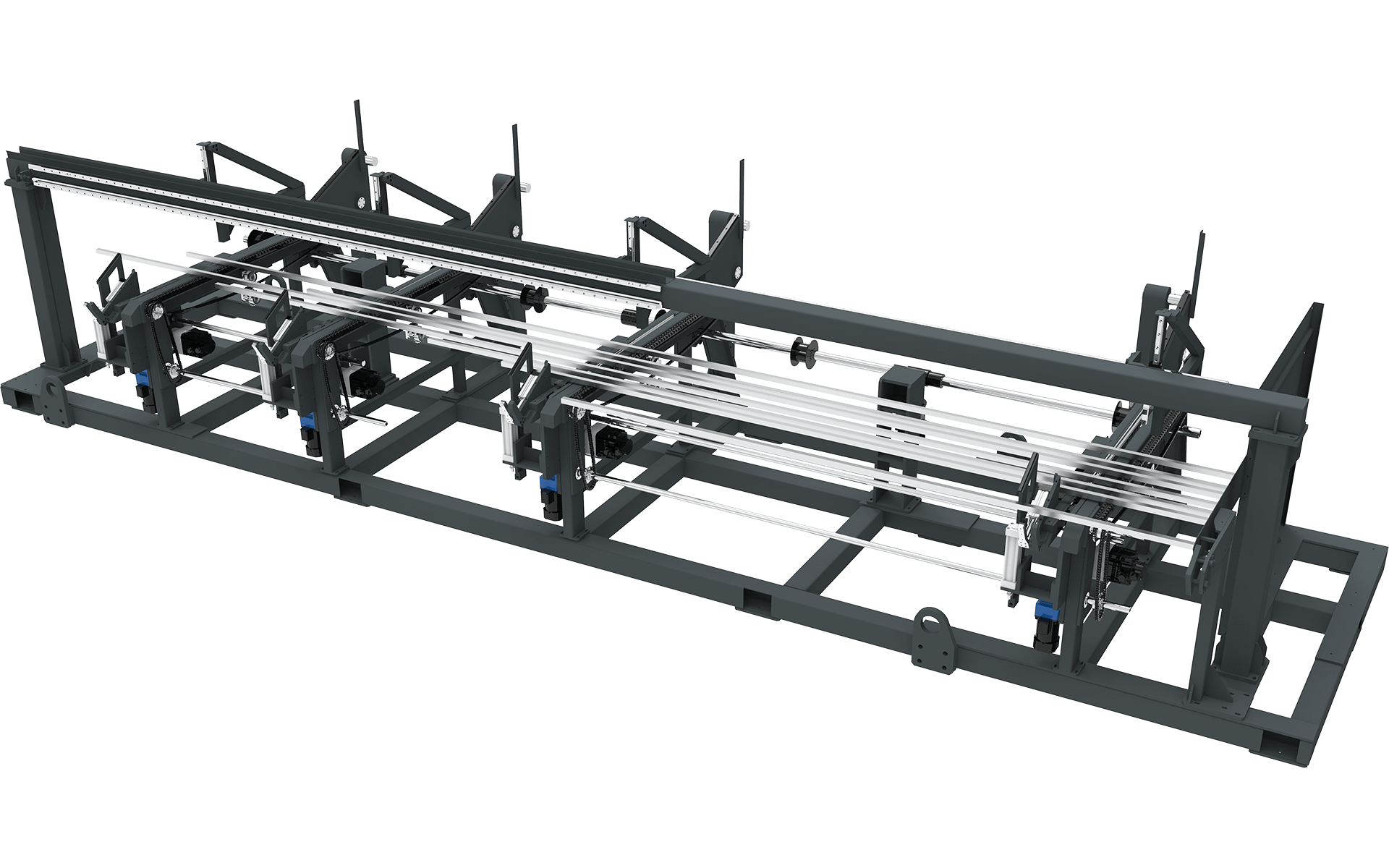

Seven-Axis Tube Delivering

TubePro supports 3-chuck of 7-axis linkage machine structure. Two moving chucks and one fixed chuck in between are able to deliver tube in production to realize zero tail waste and save more material for customer.

Active Control at Corner Cutting

The Z axis height following often unstable at corner position and damage corner quality. TubePro adopts look-forward strategy to control laser head up and down in corner turning by calculating lifting path via tube file in advance.

ACCURL BLT 5 X SERIES

3D BEVEL CUTTING LASER HEAD*:

Optional with a 3D Cutting Head, this machine-tool comes ready for a wide range of structural tube and profile laser cutting applications both on square, round, channel, beam and other profiles.

ADVANTAGE:

- Maximum ±45° bevel cutting

- Auto focus control

- Magnetic Anti-collision protection

- Swing direct-drive design

- Upper & Lower Protective window for protection of the collimation lens

- Drawer type Lower Protective window holder to facilitate quick daily inspection

- High-speed capacitive sensing,

- Cutting distance of at lowest 0.1mm

- Well supported by ACCURL Parts & Service

Interested in Metalworking Solutions?

Get Free Quote

Pricing, Technical Data & More

Why Choose ACCURL?

Industry Leading Versatility

- Customized solutions that fit your needs, goals, and budget

- Machines work with automation modules to streamline your entire metalworking process

State-of-the-Art Machines

- Our machines are simply the best with durability and efficiency you can count.

- We act as a one-stop-shop for all your metalworking machine needs offering solutions for bending, cutting, braking, and more.

Experience and Service

- With 34 years of excellence installing over 22,000 machines, our dedicated team is here to help you improve operations

- We offer environmentally friendly designs to maintain sustainability and social responsibility

Is this the right Machine for Your Goals and Operations? Get a Guide to Help You Decide