Home / Machines / 2D Laser Cutting / Fiber Laser Cutting Machine Masterline

Elevate Your Performance in 2D Laser Cutting for Sheet Metal

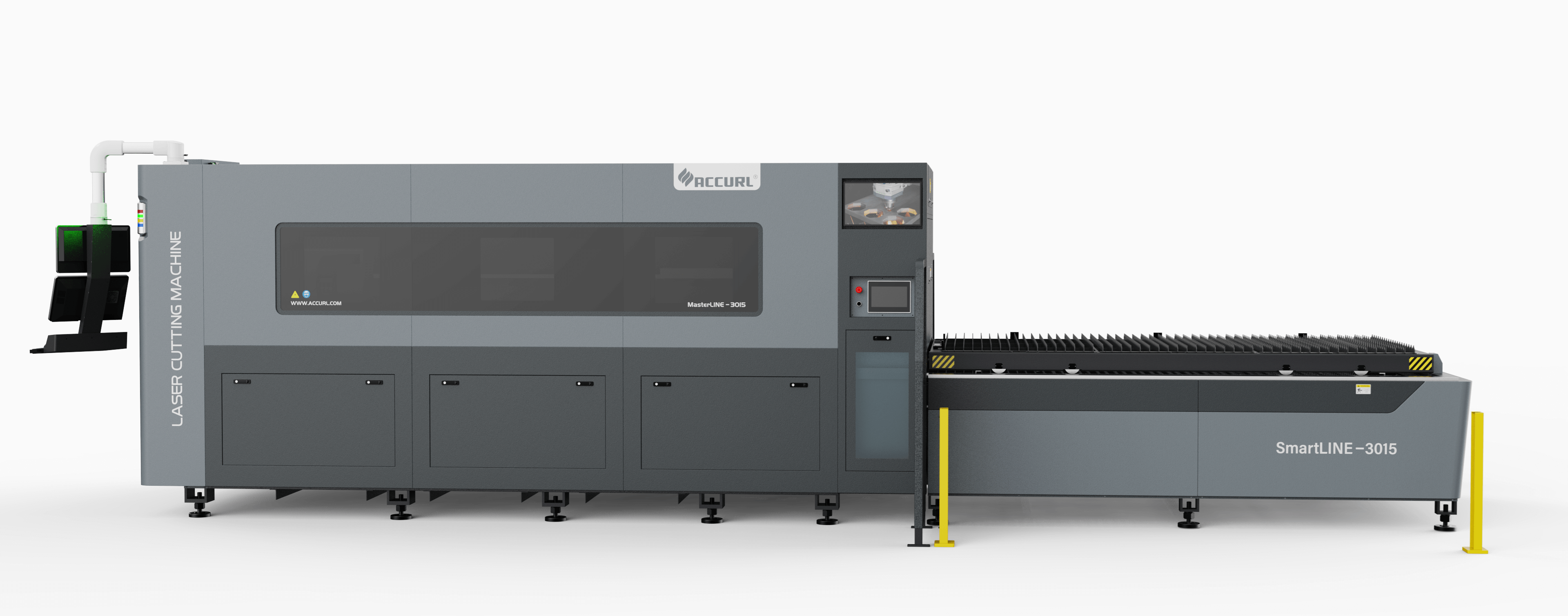

Introducing the Sheet Laser Cutting MasterLINE Series

Available models

3015 / 4020

Laser Power

IPG /MAX PHOTONICS 3KW ~ 15kW

Simultaneous axis acceleration

2G

Precision Metal Cutting at 2G Acceleration

Enhance your productivity with cutting-edge 2G axis acceleration, minimizing processing cycle times and eliminating delays. Fine-tune your laser system from 3Kw to 15Kw, leveraging Active Tools technologies for optimized metal cutting processes, ensuring industry-leading efficiency and innovation.

MAXIMIZE PRODUCTIVITY

Experience unparalleled production efficiency with swift pallet changes and a robust mechanical structure, ensuring undisputed speed and precision.SEAMLESS USER EXPERIENCE

Utilize the integrated laser parameter database, covering various materials and thicknesses, enabling immediate production readiness for any task.SEAMLESS AUTOMATION AND INTEGRATION

Ideal for unmanned operations, thanks to versatile sheet loading, unloading, and storage solutions. Seamlessly integrate with your company network for Industry 4.0 readiness, ensuring a future-proof manufacturing environment.

The winning solution for cutting your sheet matel:

Full Electric Pallet Changer !

With the full electric pallet changer alone, you can increase productivity by up to 9% (with an average of 10 pallet changes per hour). It only takes a few seconds to extract the laser-cut parts and load the new sheet metal.ADVANTAGE:

- Wide chains

- 3 times faster than hydraulic lifting platforms

- High positioning precision

- Visible exchange process

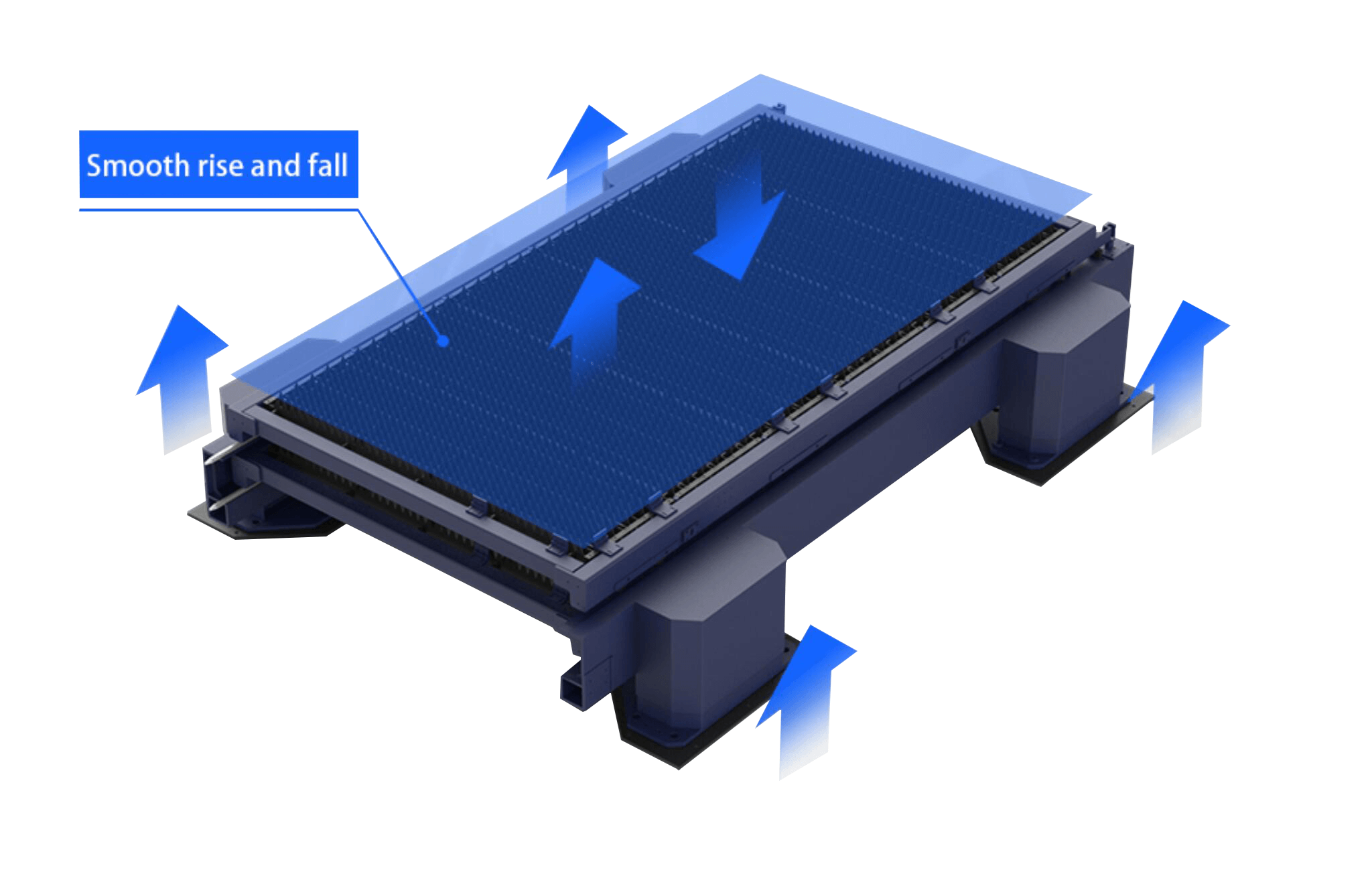

ACCURL® DYNAMIC SHUTTLE TABLE

ADVANTAGE:

- The balanced control provides smooth vertical movements for each shuttle table ensuring a controlled descent with heavy loads, preventing the collapse of parts.

- Wide chains for more stable cutting

- High-precision CNC system, protecting the machine and operators well

- Positioned by taper pins to prevent vibration and secure high positioning precision

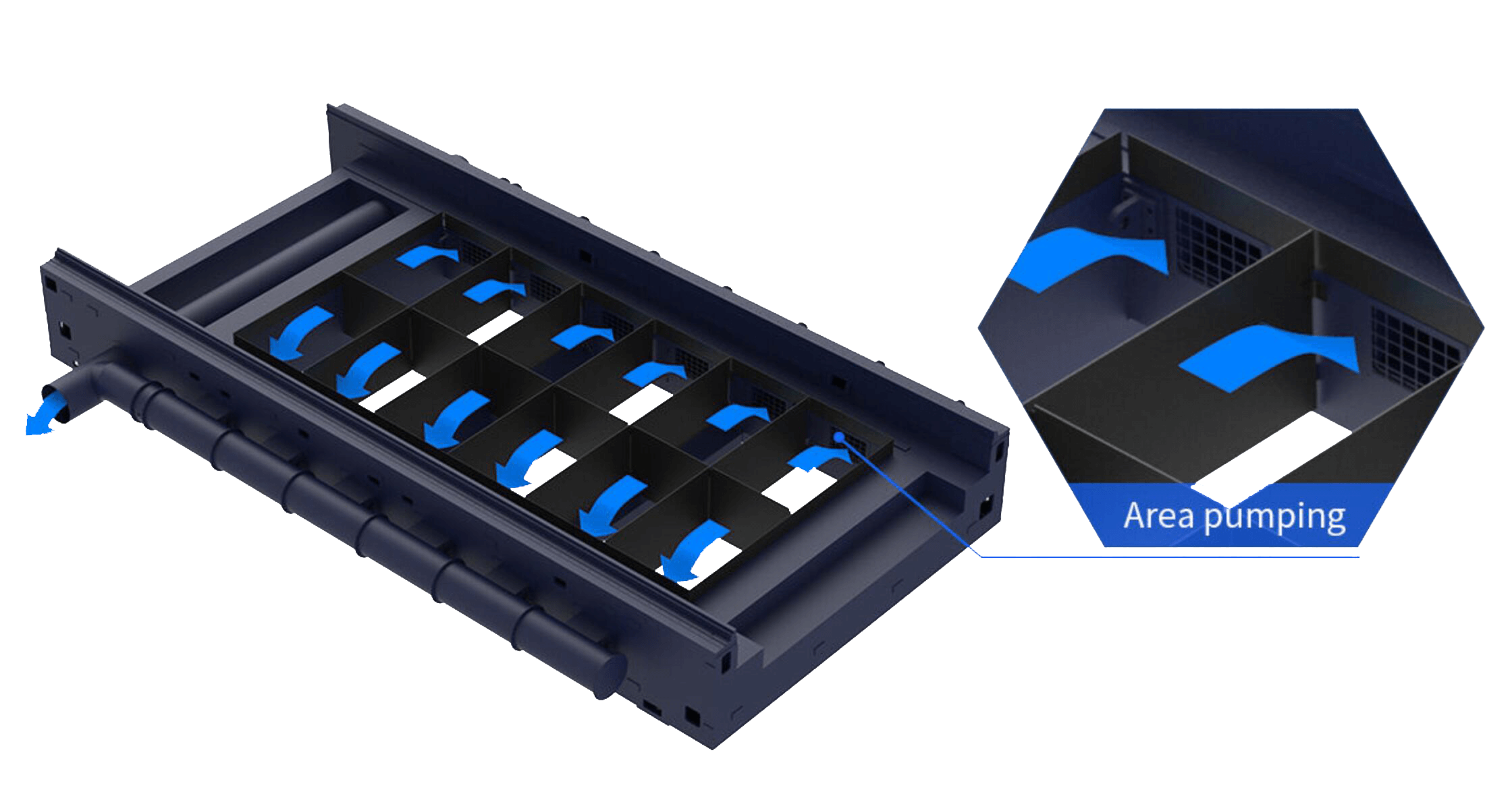

FUME EXTRACTION SYSTEM

The Efficient fume extraction by means of shutters which are controlled in accordance with cutting head position results in more efficient use of the filtration system. Therefore a smaller lower cost system can be used. The system consists of six fume extraction zones.

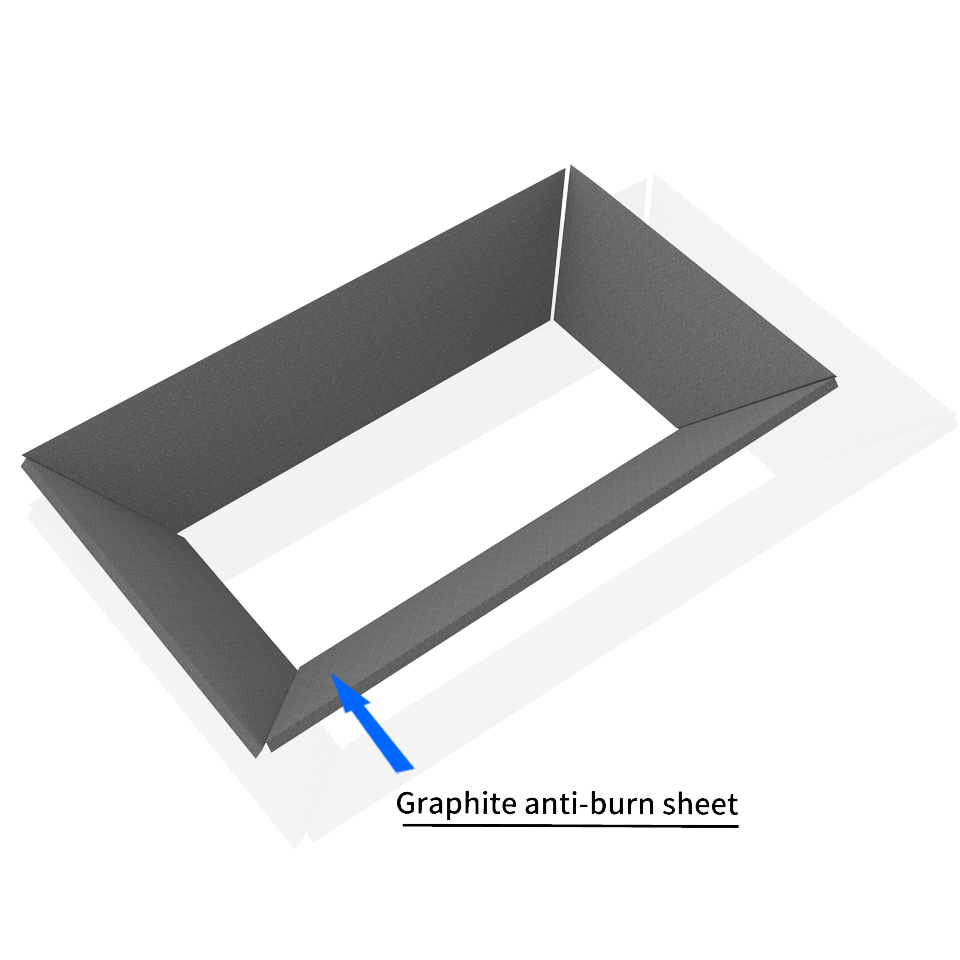

GRAPHITE ANTI-BURN TECHNOLOGY:

The area in the entire laser where the laser can shoot at is all covered and protected by manganese or graphite anti-bruning.

ALUMINIUM GANTRY STRUCTURE:

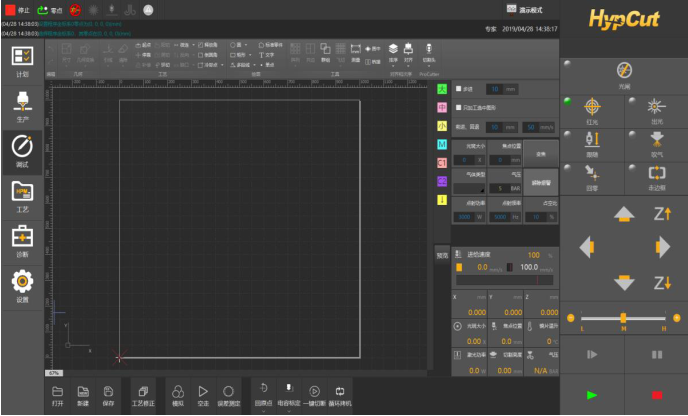

ACCURL FS-8000 Laser Cutting CNC Controller

ADVANCED:

- User friendly and touch optimized.

- Easy and efficient operation.

- Fly-cut option for significantly shorter cutting times.

- Nesting CAD/CAM software on board.

- Intuitive, step-by-step assistance for machine operators.

- Quick height adjustment for a very high and constant cutting quality.

- Integrated monitoring of peripheral units like laser sources and sensors.

- Support direct production of DXF & G code;support fast process of LXDS & NRP file generated by iCut.

THE LASER EXPERIENCE MAKE THE DIFFERENCE:

CONTROL PERFORMANCE:

PERMANENTLY

STABLE AND FAST:

FIRM. FLEXIBLE. FAST:

- Excellent cut quality

- Low process time

- Easy to maintain

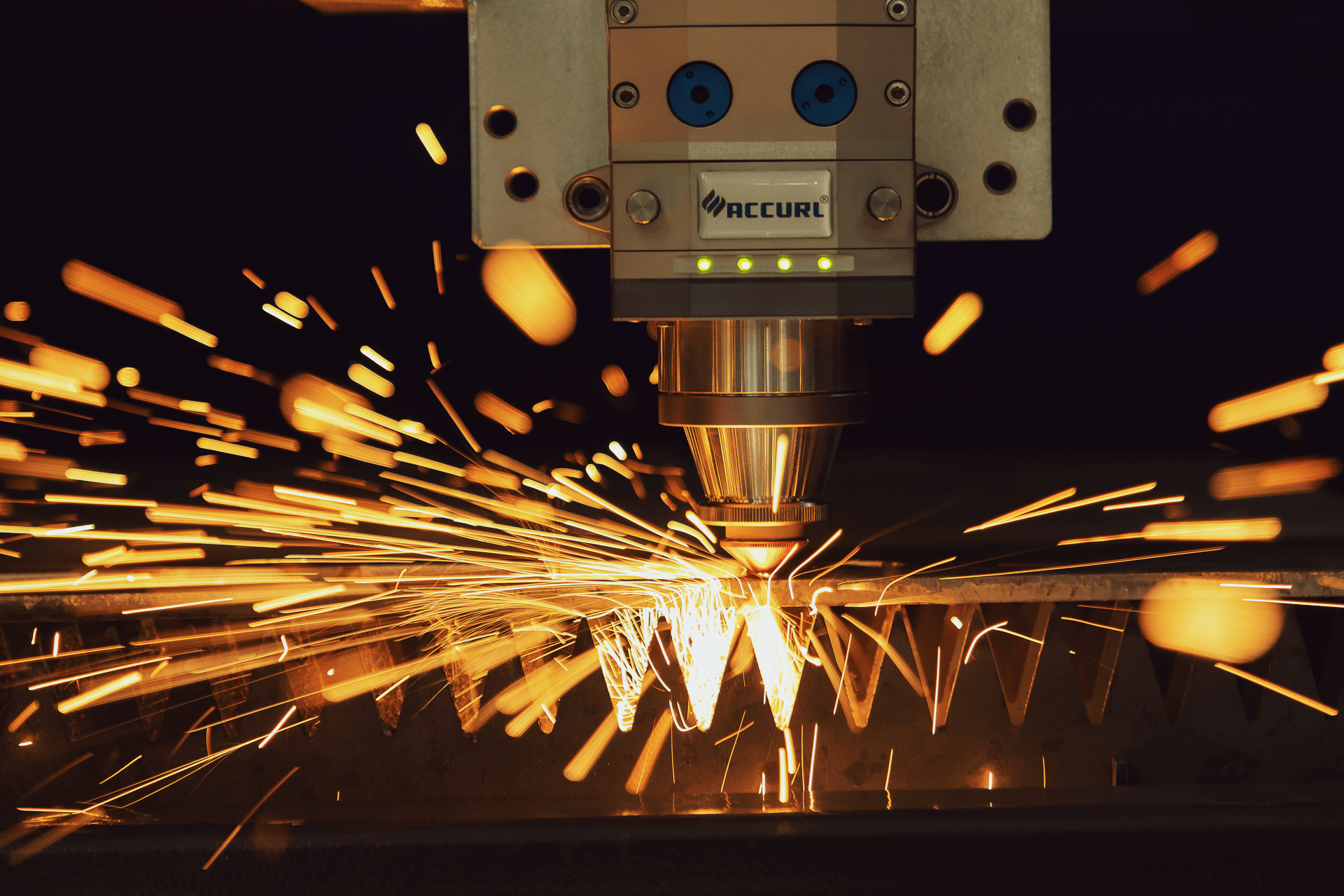

EXCELLENT CUTTING QUALITY

- Smooth cutting edges with minimal burrs

- LED operating status display

- Short process times

- Process-stable machining of thick materials

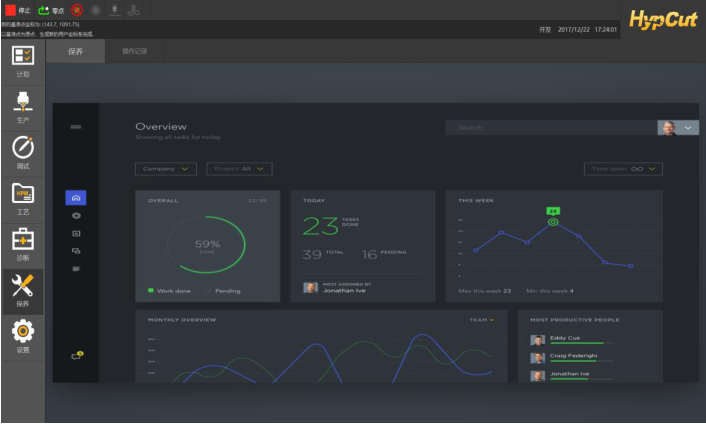

APP MONITOR:

Stable and Efficient Cutting

- Brand new optical solutions come with closed-loop auto focusing.

- Slag-free Cutting, Nozzle Cooling, and Water Cooling Sensor supportable.

Smart and Safe Processing

High cutting-edge quality.

ML Series – 2D fiber-laser sheet cutting system Technical specifications

| Performance | |

|---|---|

| Max. XY speed | 160 m/min |

| Maximum XY acceleration | 20 m/s² |

| Accuracy | ±0,05 mm |

| Repeatability | ±0,03 mm |

| Working capacity | |

|---|---|

| Processable metals | Mild steel, stainless steel, aluminum, copper, brass |

| Maximum sheet dimensions | 3.050 mm x 1.535 mm [3015] 4.080 mm x 2.020 mm [4020] 6.130 mm x 2.550 mm [6025] |