Home / Machines / Bending Machines / Press Brakes / H Brake Hybrid Press Brake Euromaster

The Perfect Hydraulic Press Brake for Your Business

Working in the metal fabrication industry in the modern day has its own set of challenges and complications. The newer technologies have allowed businesses to embrace automation and innovation in different ways, allowing people all across the world to increase their productivity and efficiency in the best way possible. One of those ways is to utilize an effective hydraulic press brake that is tailored to the needs of your business.

ACCURL has been providing hydraulic press brake machines and other types of metal-bending technologies since 1984. Our equipment is synonymous with quality, durability, and reliability.

After so many decades in the market, ACCURL has established itself as one of the top providers of hydraulic brake press machines in the world.

Get to know what makes our machines unique and why choosing our devices can help you become the industry leader.

The Mechanism Behind Hydraulic Press Brakes

It is essential to be familiar with how hydraulic press brakes work if you want to ensure that the production process will go smoothly from beginning to end.

In general terms, a CNC hydraulic press brake is a type of metal-bending equipment. It is utilized to bend large pieces of sheet metal. This action is possible thanks to the precision control provided by CNC technology, ensuring accurate bends and versatility in shaping diverse sheet metal components for various industrial applications.

Thus, companies need a hydraulic press brake or any other type of press brake to form and bend the metal they are working with and give it the desired shape.

You can choose between different options based on the needs of your business and their production needs. Some companies opt for a small hydraulic press brake as their manufacturing needs may be less diverse, while others may need a bigger hydraulic press brake to ensure that they meet the demands of their customers.

Whatever your option is, be sure that ACCURL has the perfect hydraulic press brake for you. Get to know why our machines stand out, delivering unmatched accuracy and reliability for your bending needs.

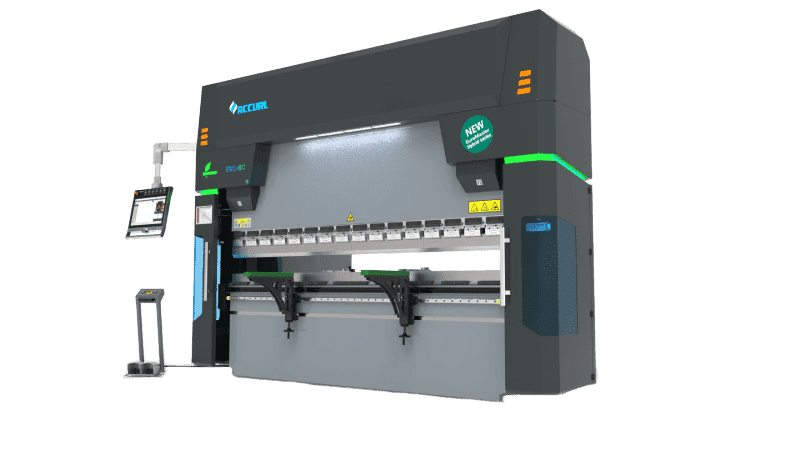

Fully-electric press brake for simple to complex sheet metal bending.

Bending Force Range

80 to 400 TONS

tons for any application

Bed Length Range

2500-4000 mm

for all production requirements

Up to 65% Energy Saving

Ram Speed 250 mm/s

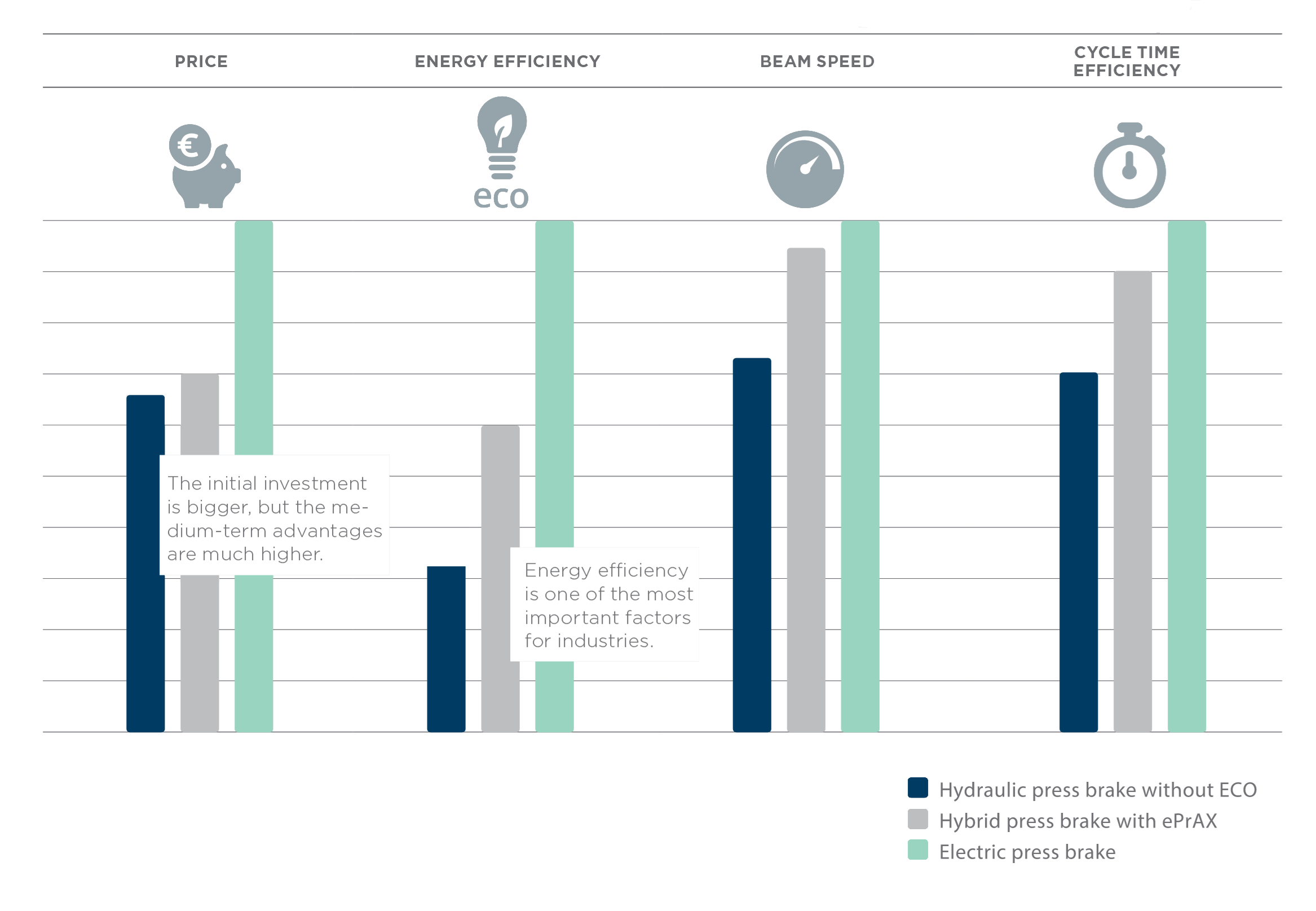

Press Brake that combines reliability and return on investment.

Accuracy, speed, flexibility, and great ease of use: EUROMASTER® ePrAX stands out from competitors’ press brakes thanks to its custom design, its modularity and to the quality of its components and fabrication.

- Energy saving

- 75 % lower consumption than hydraulic brakes on an average

- Productivity

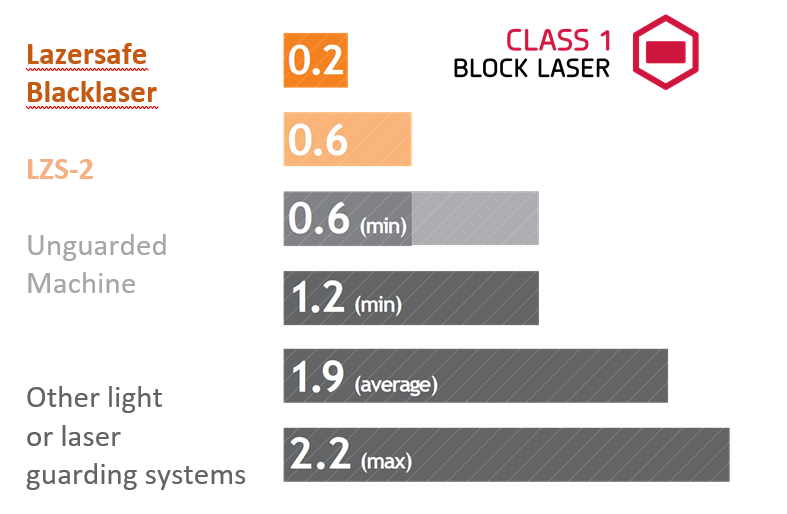

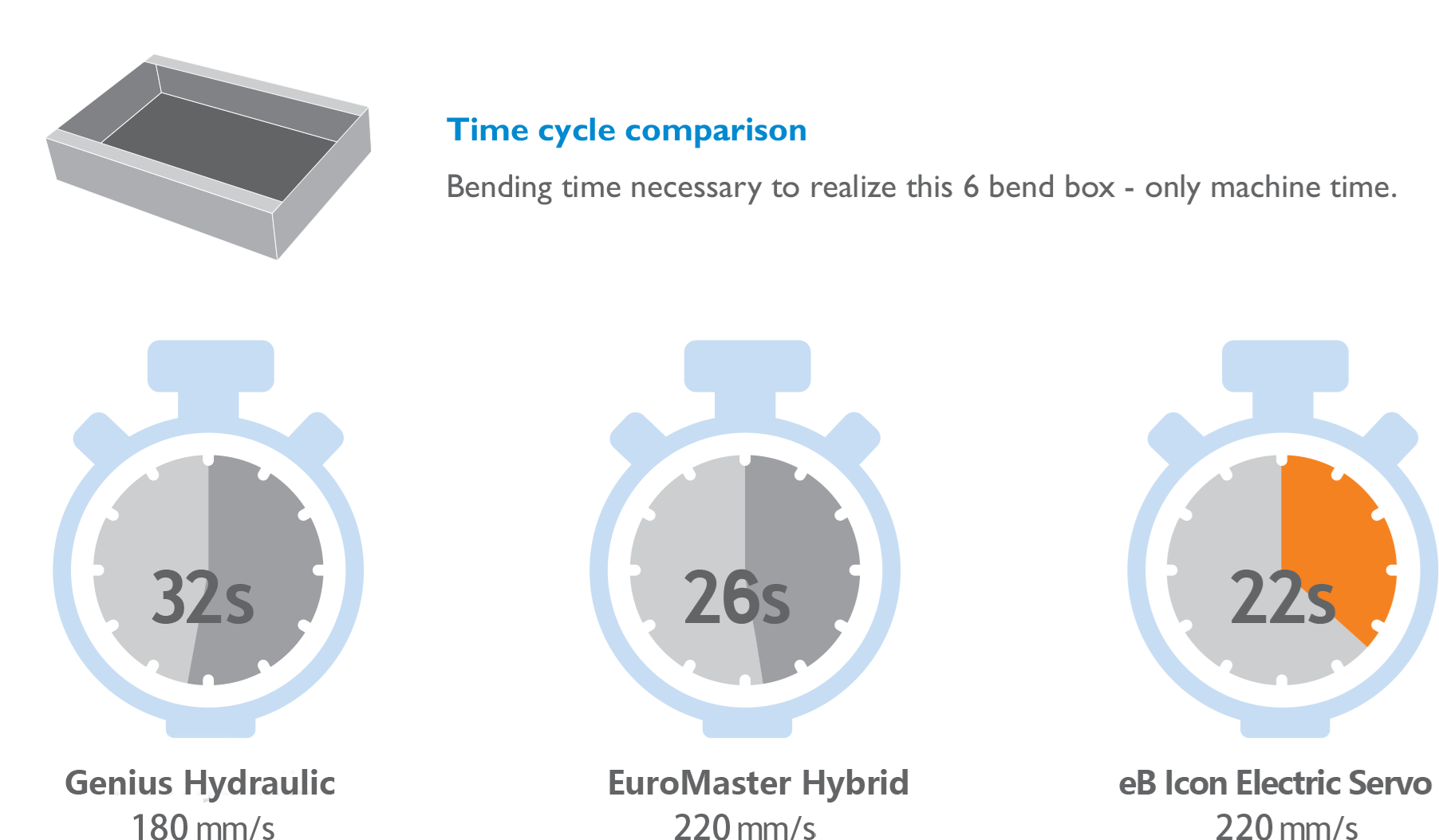

- Thanks to the high dynamic electro mechanic drive system and “IRIS” safety 35% shorter cycle times on an average.

- Low Noise

- EuroMaster allows up to 70% less noise than other machines

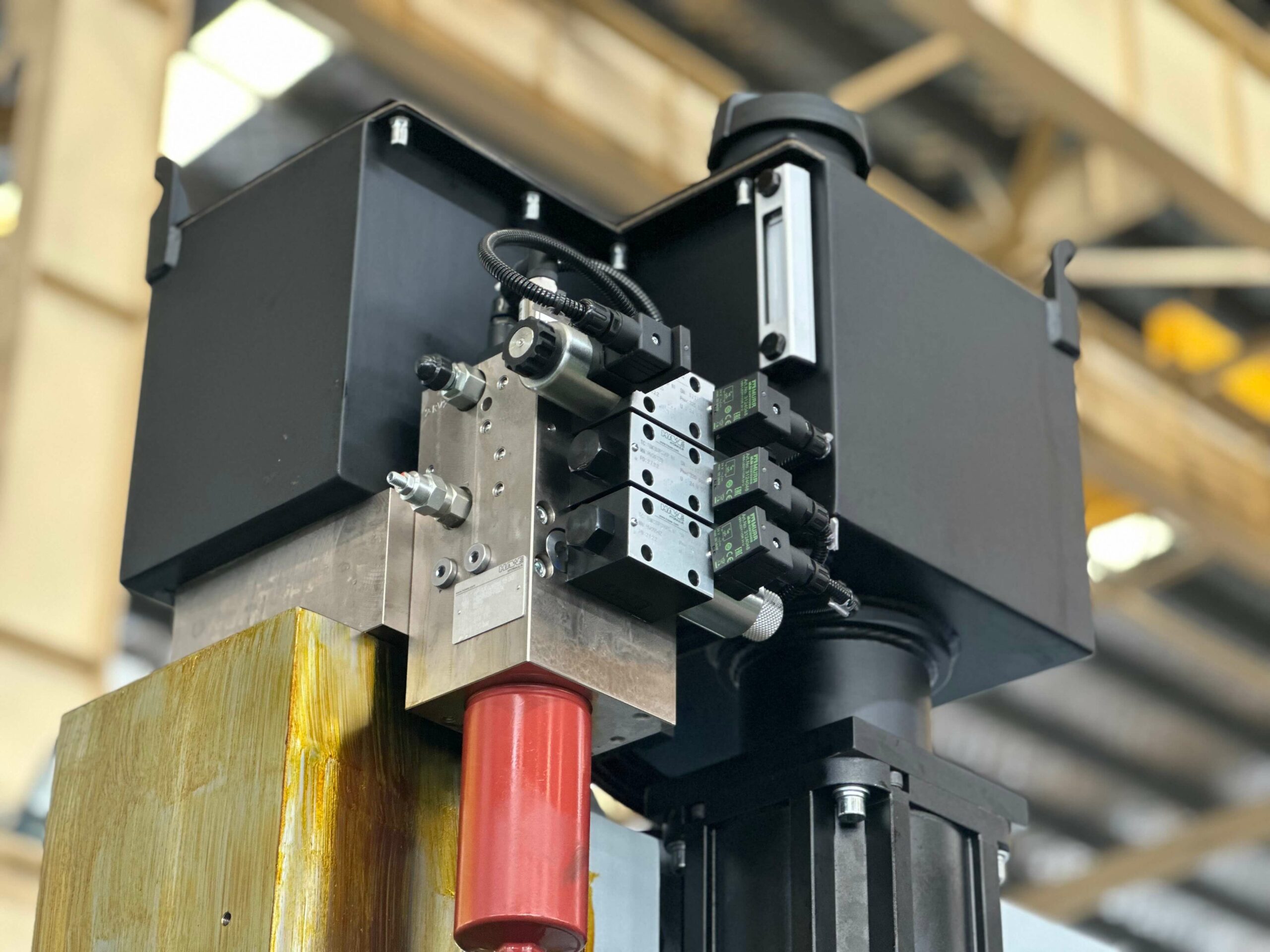

NEW ePrAX®control hybrid servo system for pump-controlled.

Advantages

The hybrid drive ePrAX adapted to the special requirements of drives for CNC press brakes:

- Respect for the environment

- Energy saving*

- Speed*

- Reduced noise*

- Less maintenance

- Less waste*

- Extreme precision

- Repeatability

For each actuator a servo motor takes over the control of power stroke and fast stroke as well as bending force. The return stroke artly takes place using temporarily stored hydraulic energy.

Dynamics with significant energy savings this principle allows efficient operation without additional cooling.

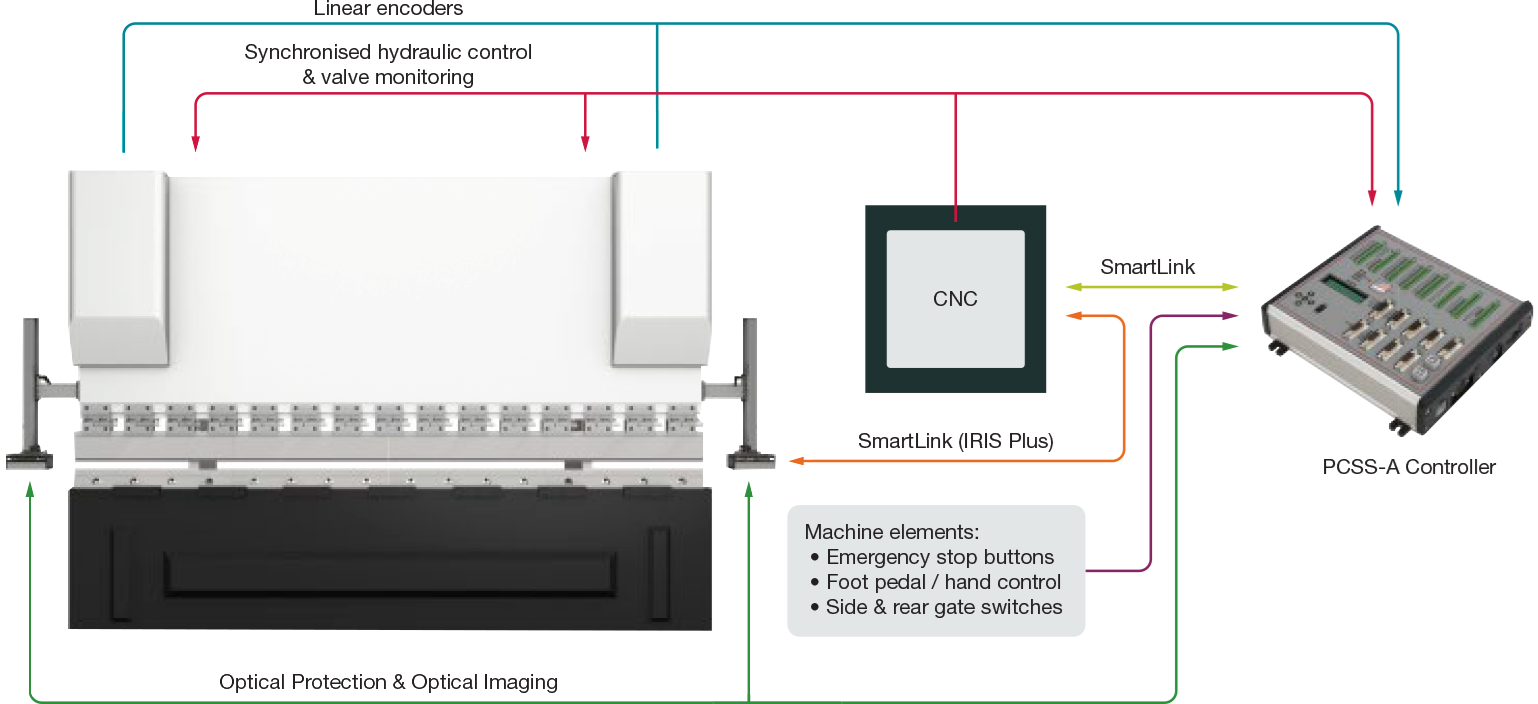

PRESS CONTROL SAFETY SYSTEM -ADVANCED:

STANDARD FEATURES PCSS-A:

SAFETY AND CONTROL:

SmartLink unifies control for improved efficiency and ease-of-use,with real-time system status display.FUNCTIONALITY & PRODUCTIVITY:

SmartLink optimizes bend programs by customizing optical protection modes in CNC and improve production efficiency.PCSS-A WITH AUTOSENSE:

Real-time monitoring of machine operation and performance, ensuring safety and compliance with international standards.

SPECIAL FUNCTIONS

FOR LAZERSAFE IRIS & IRIS PLIS:

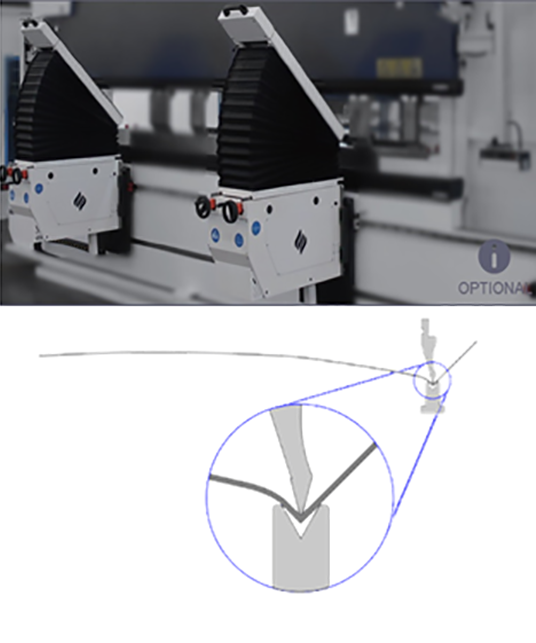

Advancements in camera-based technology make it possible to implement Special Functions that deliver higher levels of safety for the machine operator as well as greater operational stability in various environments, enhanced functionality and improved productivity.

HOW OPTICAL PROTECTION WORKS:

All functions of the optical protection system including mute point management,mode selection and user messages are embedded within the CNC system (via SmartLink).

*ADVANTAGE

- Automatic tool alignment

- Special Tools Mode

- Fast Flattening Mode

- Automatic Cycle Start (ACS)

- Adaptive Environment Sensing (AES)

- Status LEDs - Power / Front/middle/rear Sensors

- Tray mode for high speed bending of tray & box shapes

ACCURL – for years, this name has been representative of quality, reliability and flexibility

High Reliablilty

And Maximum Productivity

ACCURL® PRODUCTS MANAGEMENT

Optional with Press brake accessories: production traceability & barcode reader:

ACCURL® has developed a traceability system and a barcode reader adapted to its press brakes.It simplifies production changeovers as well as workpiece & finished part management.

PRODUCTION RACEABILITY AND

BARCODE READER:

ADVANTAGE:

- Easy Management of Workpiece & Parts

- Integration of Specific Data via Scanning

- Secure Archiving of Traceability Data (txt or xls)

- Traceability System: Monitor & Archive Production Data

- Barcode Reader: Automate Bending Program Selection

The barcode reader for press brakes offers versatile applications, including the ability to load the associated bending program for the scanned blank, eliminating errors in program selection and saving time in finding the correct program among multiple storage areas.

SHEET METAL FOLLOWER SUPPORTS:

ACCURL®believe in innovation and continuous improvement.for these reasons, ACCURL has created new servo sheet followers to support the sheet during the bend, avoiding excessive deformation.

Discover the main features of ACCURL followers:

ADVANTAGE:

- Light solution, easy to move;

- AP1 – AP2 CNC-controlled interpolated axes;

- Recommended for heavy parts or large thin plate;

- bend as closed as 70°

- Load capacity – 160kg or 350kg per support.

- Brush and support shaft dim 350×900 up to 1200 mm.

BENDING AID FOR PRESS BRAKE:SHEET METAL FOLLOWERS

- These bending aids provide valuable practical assistance (including an automatic height adjustment) for operators especially for heavy or large parts.

- Active or inactive modes that can be controlled directly on the sheet follower to avoid any safety risks (LED light located on the sheet follower).

Why Choose ACCURL’s Hydraulic Press Brakes?

ACCURL has been operating since 1984, providing high-quality equipment for the metal fabrication industry. We are a reliable CNC hydraulic press brake manufacturer. Our machines are synonymous with quality and reliability. We have helped hundreds across the nation and the world thrive and become leaders in their respective niches.

We make this possible thanks to three main pillars:

Automation

As one of the top hydraulic press brake machine manufacturers in the world, we understand that companies are looking forward to improving their productivity and efficiency levels. That's why ACCURL offers top-quality equipment that not only allows them to achieve greater levels of output capacity but also allows them to continue evolving and advancing in their manufacturing processes. Our commitment is to provide innovative solutions for enhanced productivity and operational excellence.

Innovation

Working in the metal industry can be rewarding, but it can also be quite exhausting. As a hydraulic press brake manufacturer, we are aware of the potential needs that every business may have, and we have found out that embracing innovation is the best way to overcome challenges and surpass those difficulties. Our machines can revolutionize your metalworking experience, offering more than just efficiency and precision to elevate your productivity and overall operational success.

Customer-first approach

At ACCURL, we take into account your feedback to continue improving our equipment and services. You can be sure that whenever you work with us and have a problem, our team will be more than happy to hear your feedback and make the necessary changes to our machines or services for a better experience in the future. We care about you, and that’s why we prioritize your input to enhance our products and support.

Everything You Need for Your Metalwork Business in One Place

ACCURL has been present in this industry for more than four decades, providing people with the equipment they need for their metalwork business. Whether it is a hydraulic press brake or perhaps a panel bending machine, you can be sure that you will be able to find what you’re looking for within our categories.

We are constantly improving our business to ensure that we are compliant with the demands that businesses may have in a technology-driven world. Whatever you think you may need for your metal fabrication company, it’s likely that we have it covered. Our commitment to staying ahead in technology and innovation allows us to offer cutting-edge solutions tailored to your evolving needs, ensuring your success in the modern market.

If you’re ready to embrace innovation and automation within your business and start improving your productivity levels, don’t hesitate to contact us. We’re here for you!

Equipped with the Latest Technology

Our EuroMaster model is equipped with high-resolution DELEM DA69T Touch 3D Graphical Control for user friendly precision and visual creation. In fact, it’s designed for meticulous accuracy of ± 0.03 mm for expertly crafted results every time.

Is this the right Machine for Your Goals and Operations? Get a Guide to Help You Decide