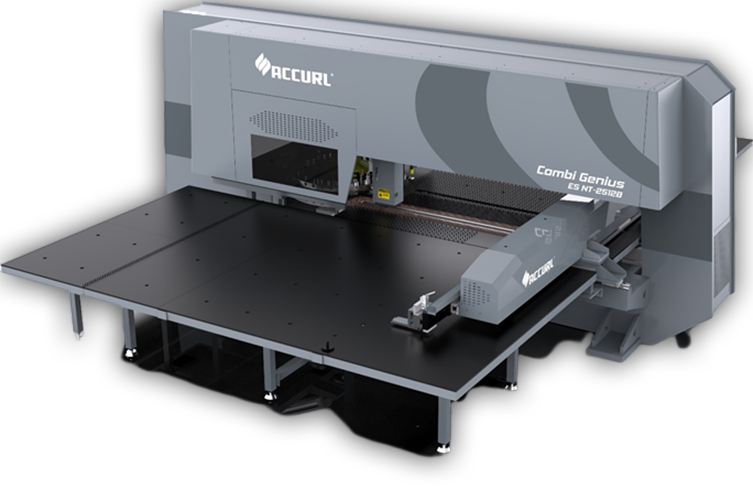

Home / Machines / Punching & Combi / Punching and Laser Cutting Combined Machines

Punching and Laser Cutting Combined Machines

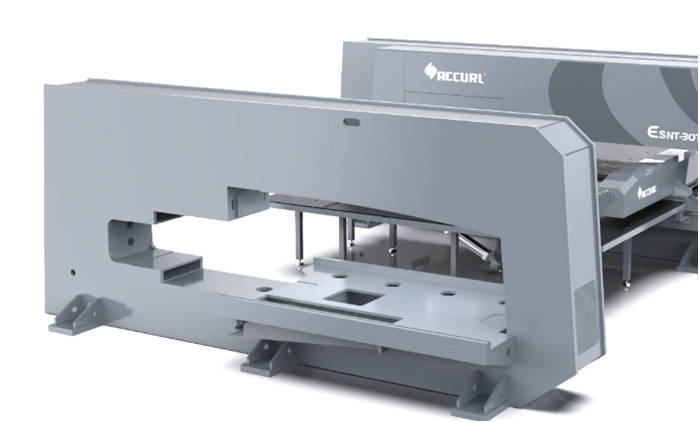

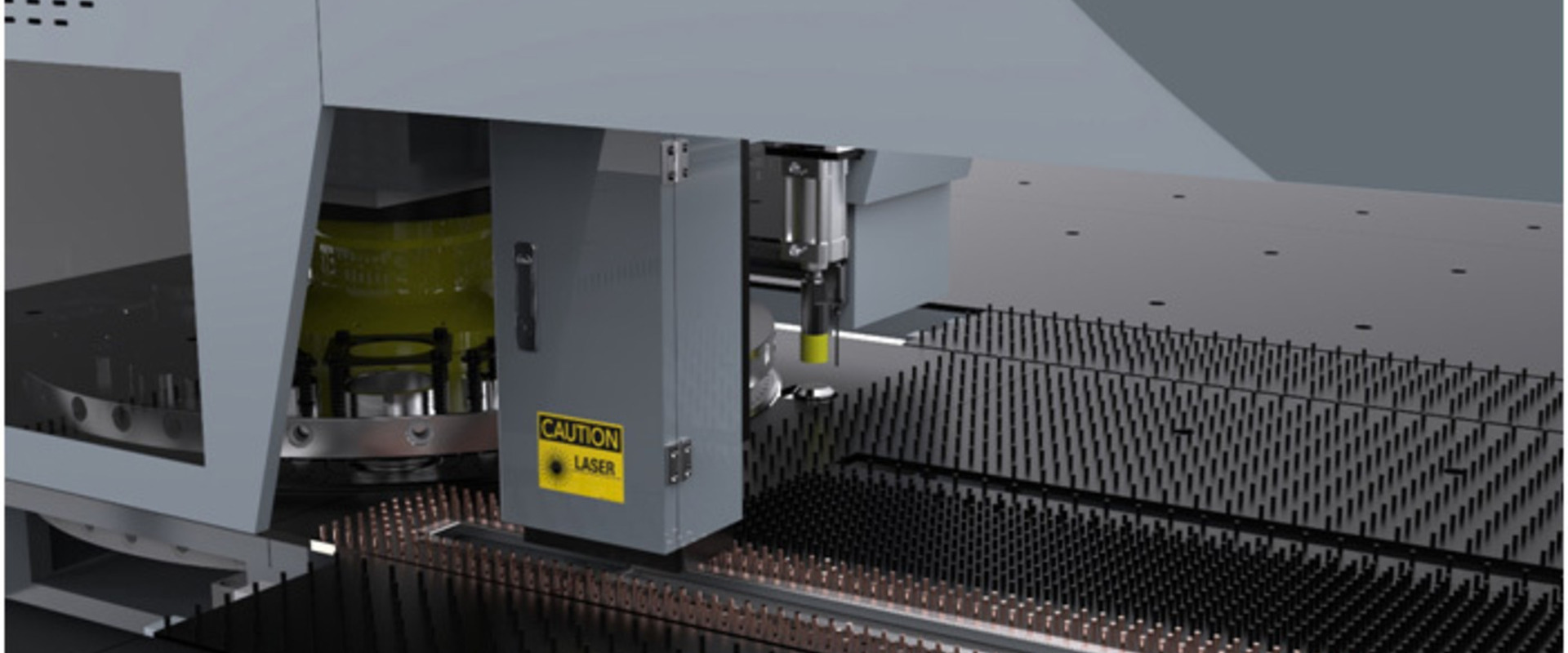

Introducing the NEW ES NT-30T Punch Laser Combined Machine

The CNC punch and laser combined machine not only has servo punching processing technology, but also has the characteristics of high laser cutting efficiency and good cutting quality, which can realize punching holes, forming, laser cutting and other functions, and provide a new intelligent manufacturing solution for your production. The combined machine consists of a punch machine, a laser cutting system and an electrical system. The combined machine adopts a complete set of German Rexroth CNC system and drive.

Rigid Press Frame

Improved stability in the punching process using 12.5% thicker material for the press side frames and improved stiffness of base component.

O-type closed integral welding press frame special for servo punch press.

Motion and Table

Improved stability in table motion by utilizing a two point LM guide support for high speed processing. In addition, ball screws are now used for the X and Y axes providing improved maintenance.

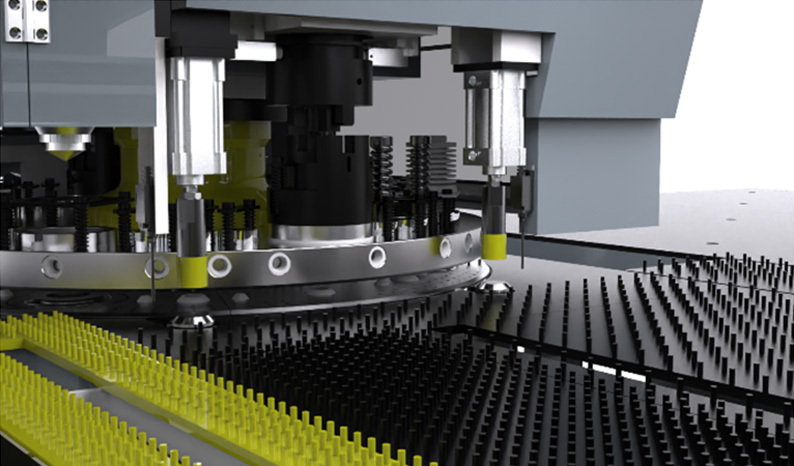

Full Auto Indexed Station

Tools are rotatable in 0.01° increments enabling the processing of complex shaped parts with the minimum number of tools.

Tool change takes less than 3 seconds to complete total turret movement and just 0,6 seconds for single tool.

The turret itself is made of s50C and undergoes rigorous testing.

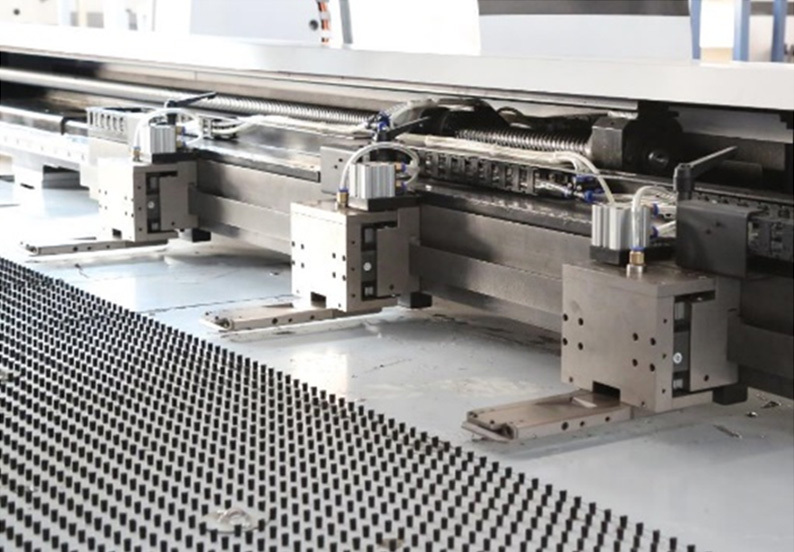

Automatic Pneumatic Clamps

When punching thinner material, one of the problem is to control the sheet movement at non clamping area. To eliminate this matter 3 clamps or more is available.

Automatic Clamp positioning reduces setup time and errors ,and provides machine runtime flexibility and productivity

Turret Punch System:

Name | Specification | Unit | |

Press Capacity | 300 | KN | |

Max. Sheet Size | X axis | 5000 (With one re-positioning) | mm |

Y axis | 1250 | mm | |

Max. Sheet Thickness | 6.35 | mm | |

Max. Diameter | Φ88.9 | mm | |

Max. Nibbling Rate | 1800 | hpm | |

No. of Clamps | 3 | pcs | |

Turret Stations (Auto-index station) | 32(2B) | pcs | |

No. of Controlling Axis | 5(X, Y, T, C, A) | pcs | |

Tool Configuration | 16A/10B/2BAI/2C/2D | ||

Max. Feeding Speed | X axis | 90 | m/min |

Y axis | 80 | m/min | |

Simultaneous | 110 | m/min | |

Punching Accuracy | ±0.10 | mm | |

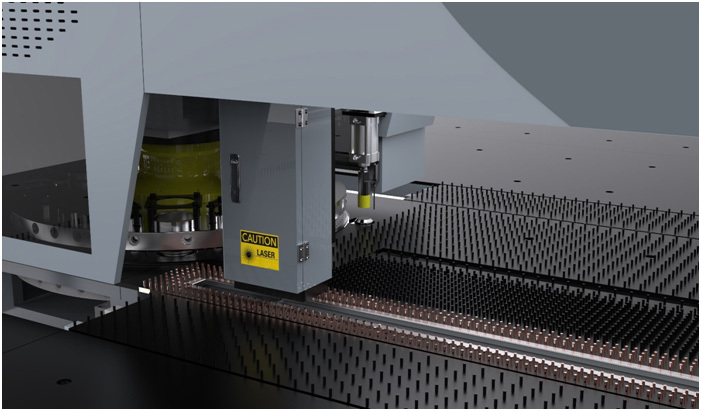

Laser Cutting System

The laser cutting system mainly includes three parts: cutting head, fiber laser generator, gas circuit and water circuit system.

Parameter | Unit | technical indicators |

Laser Power Output | W | 3000 |

Working Area | mm | 1500x2000mm |

Cutting Accuracy | Mm | ±0.1 |

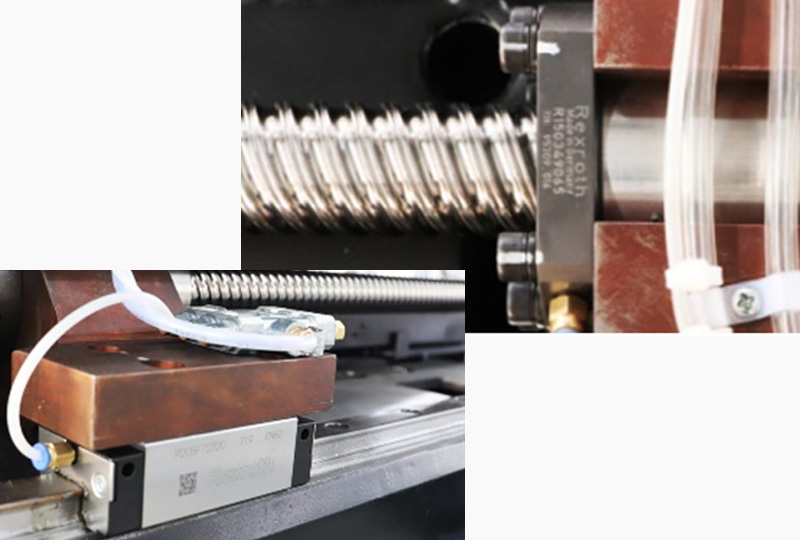

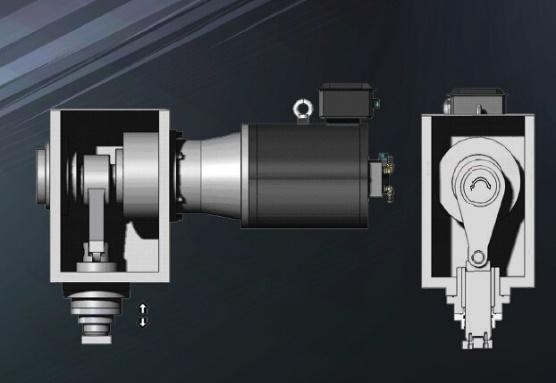

REXROTH Servo Transmission Technology

Introducing foreign advanced technology and combining with our company’s mature products, we develop a high-grade numerical control machine. The system and transmission adopt a complete set of German Rexroth configuration, the main motor is air cooled, and the driving system can be remotely diagnosed, with low noise, high speed, and high efficiency features.

Full electrical servo CNC turret punch press:

- Advanced REXROTH CNC Servo system to control the RAM stroke distance on both ends, and depth of each punch becomes with 0.01mm accuracy.

- The AC punch servo motor can be programmed for various applications.

I) High speed applications.

II) Low noise applications.

III) Forming applications.

Combined Laser Cutting

Punching, forming, marking, bending, laser cutting – all in one.

Servo-electric punching and fiber laser cutting technologies, no laser gas required.

Small floor space needed even with automation modules.

Laser power: 3 kW or 4 kW

Positioning speed: 108 m/min

Max sheet size 1,500 mm x 2,000 mm

Automatic Small Material Chute

Chute size: 420×1300, the workpiece in this size range can be dropped to the bottom finished product drop bin.

Interested in Metalworking Solutions?

Get Free Quote

Pricing, Technical Data & More

Why Choose ACCURL?

Industry Leading Versatility

- Customized solutions that fit your needs, goals, and budget

- Machines work with automation modules to streamline your entire metalworking process

State-of-the-Art Machines

- Our machines are simply the best with durability and efficiency you can count.

- We act as a one-stop-shop for all your metalworking machine needs offering solutions for bending, cutting, braking, and more.

Experience and Service

- With 34 years of excellence installing over 22,000 machines, our dedicated team is here to help you improve operations

- We offer environmentally friendly designs to maintain sustainability and social responsibility

Is this the right Machine for Your Goals and Operations? Get a Guide to Help You Decide