Home / Machines / 2D Laser Cutting / Laser Welding & Cleaning Systems

SMART HLW - Handheld Laser Welding & Cleaning Systems

Introducing the Laser Welding & Cleaning Systems

Available models

1000w / 1500w / 2000w / 3000w

Laser Power

IPG /MAX PHOTONICS 1KW ~ 6kW

Material Welding Range

Stainless Steel | Stainless Steel | Stainless Steel | Aluminum

A FAMILY OF PRODUCTIVE LASER PROCESSING TOOLS:

SMART HLW handheld laser welding and cleaning systems are fast, easy to learn and operate, and produce high quality, consistent results across a wide range of materials and thicknesses. Pre-weld and post-weld laser cleaning functionality optimizes weld quality while increasing productivity.

REVOLUTIONIZING THE WELDING INDUSTRY.

The Laser welding power up to 3000 W is easily adjusted with intuitive controls to quickly dial in optimum weld settings for various materials and thicknesses. With up to 74 stored preset and user-defined process parameters, novice welders can be trained and welding in a matter of hours.

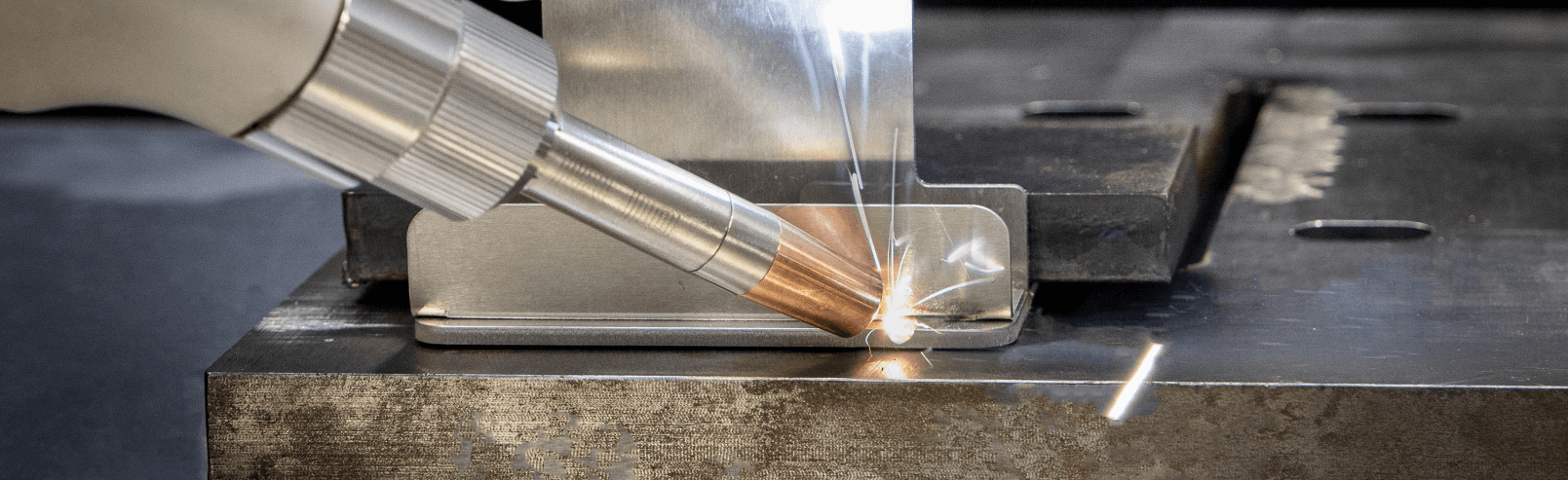

Handheld fiber laser welding machine has the best fiber laser beam for fast welding speed, high quality weld seam and no consumables.

HANDHELD LASER WELDING TECHNOLOGY:

SMART HLW handheld laser welding and cleaning systems are fast, easy to learn and operate, and produce high quality, consistent results across a wide range of materials and thicknesses. Pre-weld and post-weld laser cleaning functionality optimizes weld quality while increasing productivity.

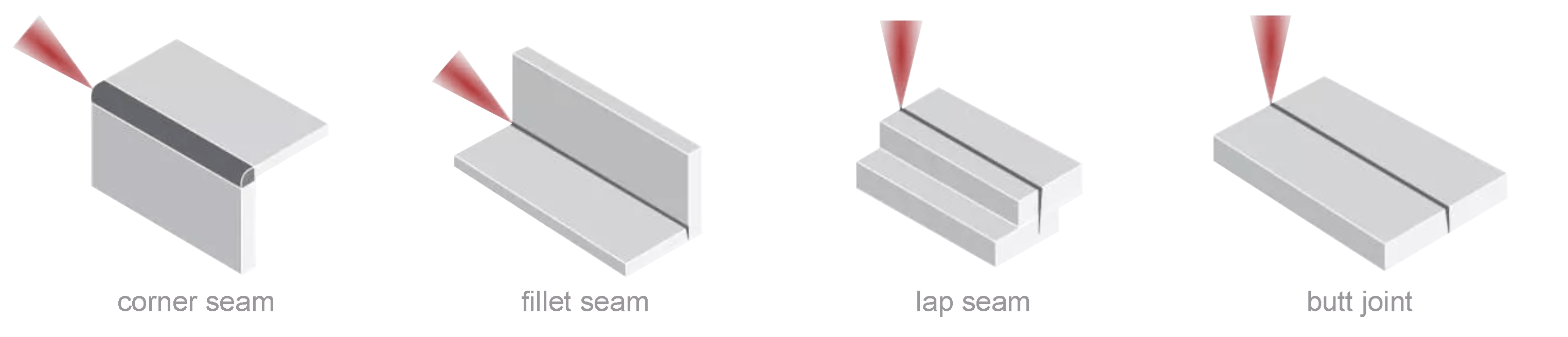

LASER WELDING:

The High speed, low heat input, and a small HAZ make laser welding thick, thin, reflective materials, and materials with dissimilar thicknesses far less challenging for all skill levels

LASER PRE-CLEANING:

The Pre-weld cleaning removes rust and other contaminants from materials and increases weld quality. This is much faster than manual cleaning and uses no chemicals or abrasives.

BENEFITS:

- Low heat input for minimal part distortion or deformation

- Built-in factory presets for all materials and thicknesses

- High-speed welding across a wide range of materials and thicknesses

POWERFUL, RELIABLE AND ENERGY-EFFICIENT LASER SYSTEM SOLUTIONS *

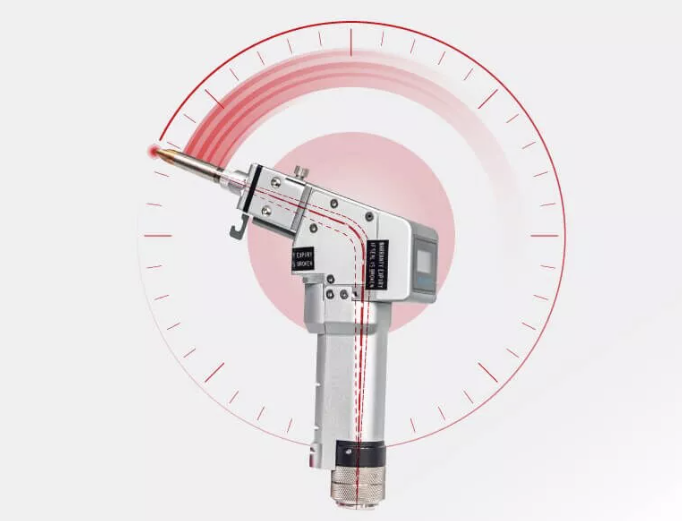

ACCURL PRO SWING LASER HEAD:

The ACCURL laser welding machine is equipped with a modern welding head with a moving beam and a swinging electrical system. It has a patented mechanism to drive the focusing lens, allowing you to automatically change its position, thereby changing the width of the beam.VERSATILE WITH ALL WELDING MODES

- It can be equipped with nozzles of various angles to meet the welding requirements of various products.

- Operators can instantly switch between presets to accommodate many material thickness combinations

HANDHELD LASER WELDING & CLEANING SYSTEM:

- SMART HLW enables dramatically faster welding, is easier to learn and operate, and provides higher-quality, consistent results across a wider range of materials and thicknesses than MIG or TIG with minimal distortion, deformation, undercut or burn-through.

- ACCURL® Hand laser welding machine with lighter laser head and ergonomic design.

BENEFITS:

- Handheld Laser Processing Head-Cut/Weld

- Multiple safety protection with auto beam off function once the nozzle goes away from workpiece.

- Various tip assemblies in standard kit to fulfill cutting, welding

- Wide welding seam, low porosity and excellent melting pool protection

ADVANTAGES & BENEFITS:

SMART HLW enables dramatically faster welding & is easier to learn and operate than MIG or TIG. HLW provides higher-quality, consistent results with minimal distortion or part deformation| Traditional Systems | SMART HLW Systems | |

|---|---|---|

| Speed | Average | Fast - Over 4X Faster than TIG |

| Quality | Depends on user experience | Consistent high-quality results |

| Learning curve | Steep | Quick and easy |

| Part Setup | Critical and time consuming | Minimal and fast |

| Material flexibility | Limited with consumables changes | Wide range with no set up |

| Heat affected zone | Large | Small |

| Distortion & Deformation | High | Very Low |

| Wobble welding | No | Yes - up to 5 mm |

| Pre-Weld Cleaning | No | Yes - Removes rust, oxides, oil & grease |

| Post-weld Polishing | No | YES- Removes soot, debris & discoloration |

PARAMETERS:

The following table values are variable, depending on the final configuration and model of the device. Fixed parameters for each model are given in the quotation.| Material | SMART HLW-1000 | SMART HLW-1500 | SMART HLW-2000 |

|---|---|---|---|

| Stainless Steel | up to 2.5 mm | up to 4 mm | up to 6.35 mm |

| Galvanized Steel | up to 2.5 mm | up to 4 mm | up to 6.35 mm |

| Mild Steel | up to 2.5 mm | up to 4 mm | up to 6.35 mm |

| Aluminum 3 & 5 Series | up to 2.5 mm | up to 4 mm | up to 6.35 mm |

| Nickel Alloys | up to 1.5 mm | up to 4 mm | up to 5 mm |

| Titanium | Large | Large | Large |

| Copper | High | High | High |

PARAMETERS:

| MODEL NUMBER | SMART – HW |

| Conduction type | fiber |

| Wavelength | 1080mm |

| Laser Power | 1000W / 1500W / 2000W |

| Frequency | 20-5KHz |

| welding head weight | Approximately 760g |

| Output focal length | 120mm |

| Cooling method | Water cooling |

| Fiber length | 5M/10M/15M |

| Port | 1 way gas |

| Power consumption | ≤6KW |

| welding wire model | 0.8-1.6mm |

| Air pressure requirement | 4-6Bar (Select nitrogen,argon or compressed air according to process requirements.) |

| Electricity demand | 1KW/1.5KW-AC220V/50/60Hz |