Home / Machines / Bending Machines / Press Brakes / Tandem Press Brake Genius Pro Series

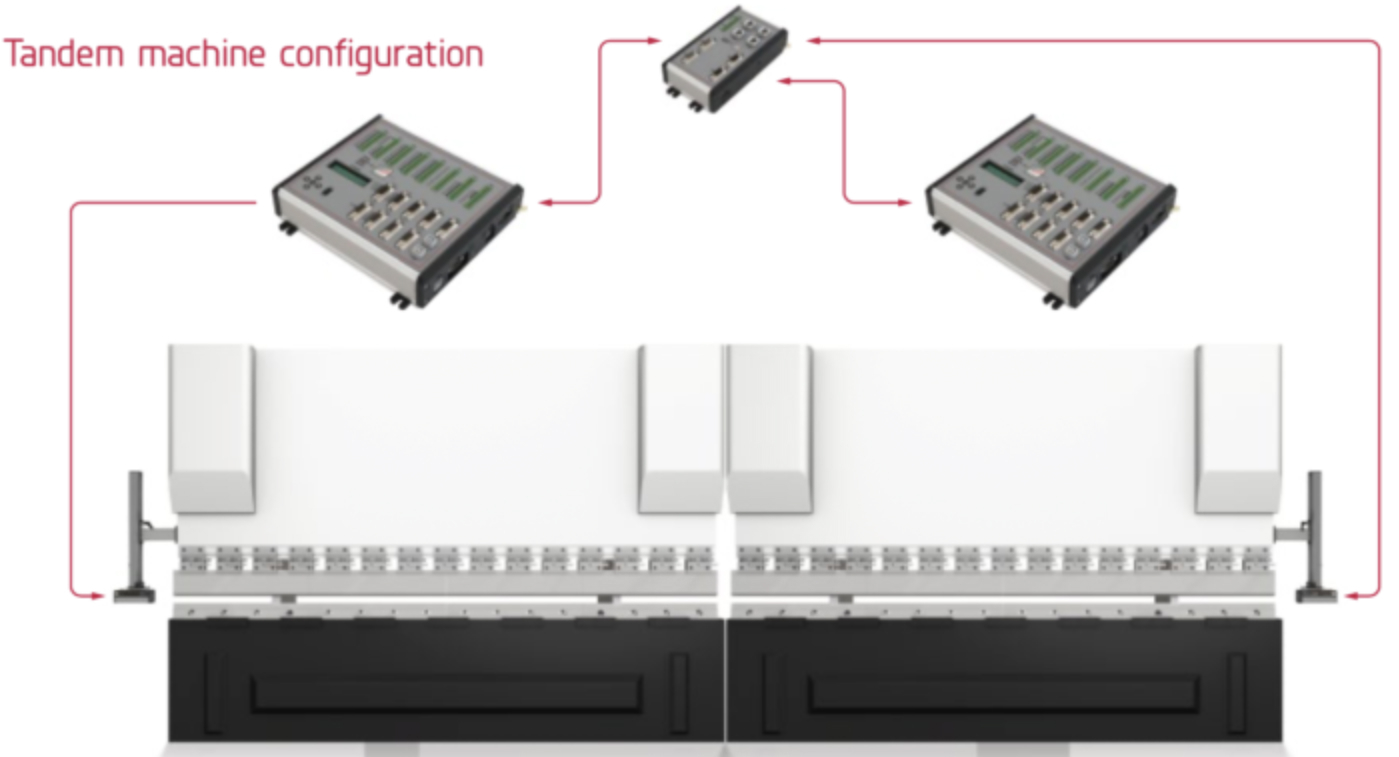

Accurl press brakes can be connected in Tandem of 2, 3, 4, or more machines.

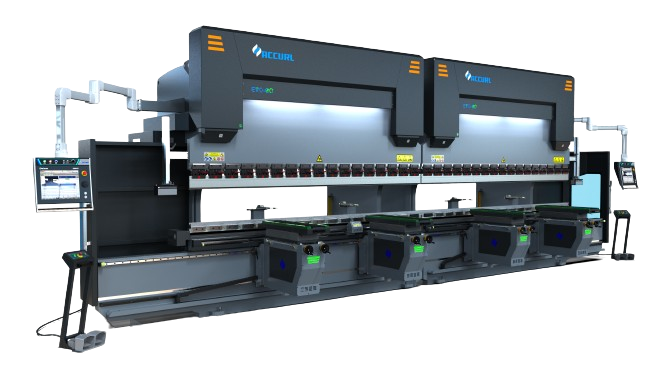

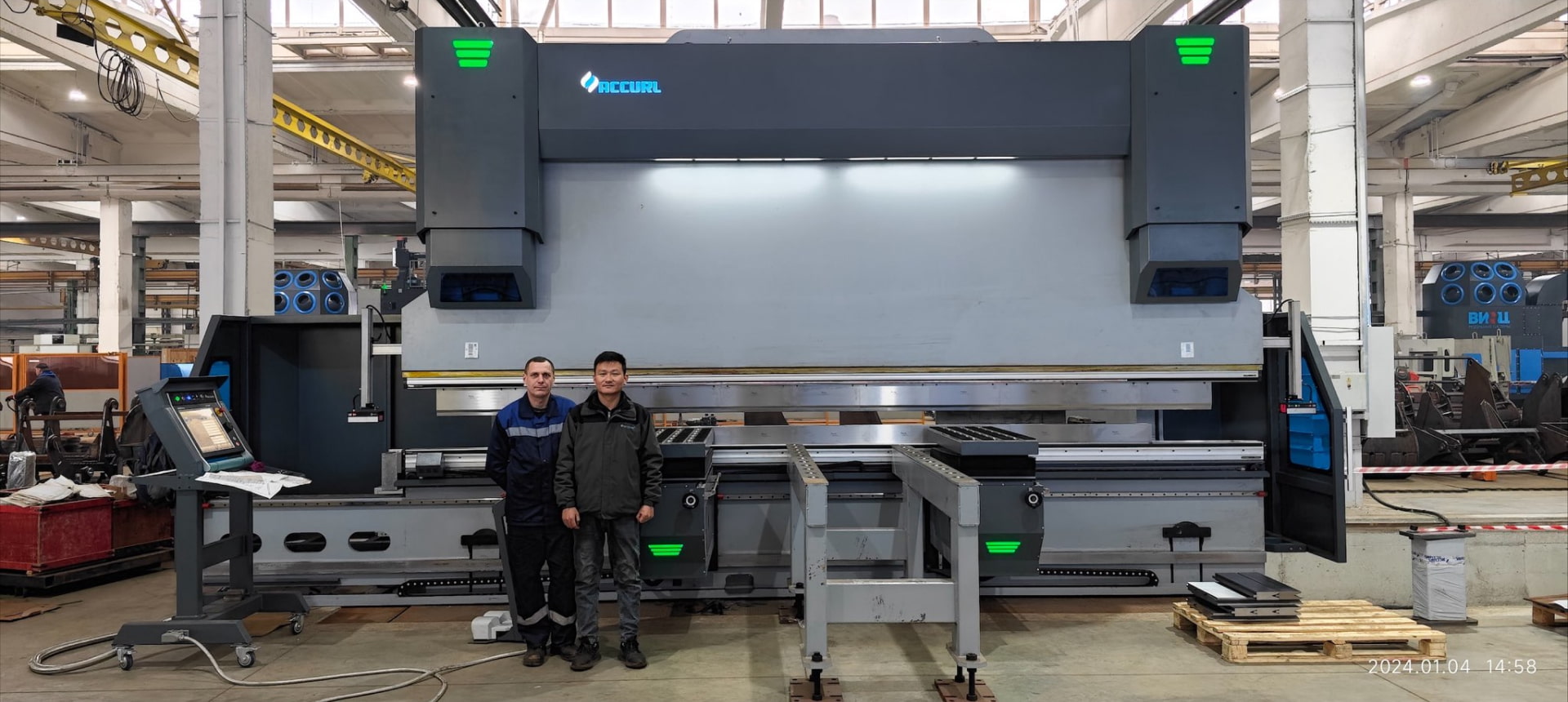

Introducing the Tandem Press Brake Genius Pro Series

Bending Force Range 200 to 2000 TONS

Bed Length Range 6000-24000 mm

DELEM CNC controller

Up to 45% Energy Saving

CE-certification, machine is CE-approved

Industry 4.0 Ready

Dual servo drive hybrid bending solution for high tonnage market.

Bending Force Range

200 to 2000 TONS

tons for any application

Bed Length Range

6 – 12 Meters

for all production requirements

Up to 45% Energy Saving

Dual modular tanks, 60% less hydraulic oil.

Optional with Tandem Adaptor enhances machine safety in both single and tandem configurations.

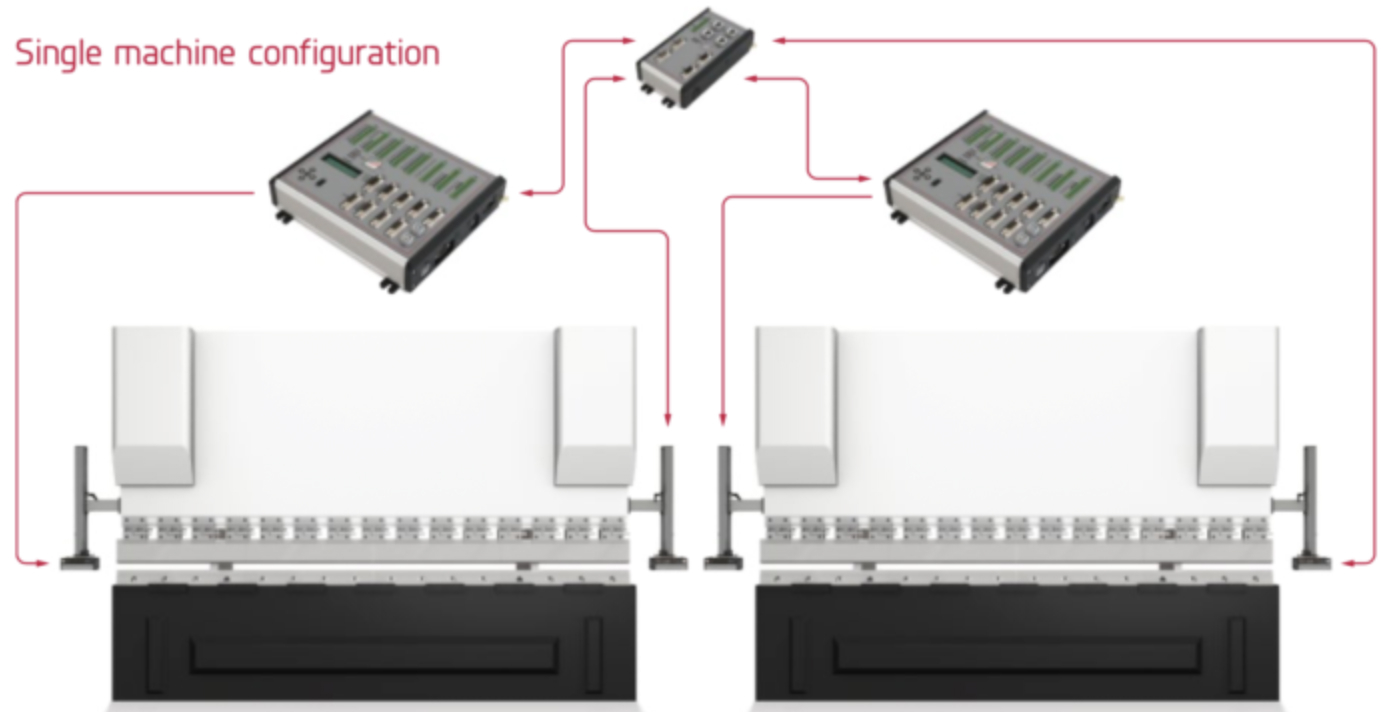

ACCURL® advanced Tandem Adaptor solution synchronies safety functions and control across both machines and when paired with the dedicated LZS-XL optical system, it provides flexible guarding in both single and tandem configurations.

SOLUTION FOR TANDEM PRESS BRAKE:

*Advantage:

- Advanced camera technology for protection

- Safety maintained without interruption

- Flexible guarding in single & tandem configurations

- Quick transition from single to tandem with custom bracket system

SINGLE MACHINE CONFIGURATION:

The machines can operate independently with high speed and separate LZS-XL optical protection.The performance is enhanced with a minimum speed change point of 3mm for both flat sheet and box bending.

Press Brake that combines reliability and return on investment.

ACCURL Heavy Duty stands out as a premier press brake series globally, excelling in the price-to-quality ratio. With a commitment to efficiency, it features a short delivery time, swift assembly, and a myriad of advanced accessories and optional devices. Elevate your bending capabilities with Accurl Giant series, synonymous with quality, reliability, and innovation.

ACCURL patented E-HYBRID hybrid servo system,- featuring ACCURL’s exclusive hybrid servo technology EVO-GO, ensures continuous operation. With dual modular hydraulic systems, even in challenging conditions or a hydraulic system failure, the machine seamlessly transitions to a single servo pump, exemplifying unparalleled reliability and uninterrupted productivity.

THE”GREENER”COMPETITIVENESS:

- Energy saving

- 45 % lower consumption than hydraulic brakes on an average.

- Hydraulic System:

- Incorporating a dual modular tank design, reducing hydraulic oil volume by 60%.

- Productivity

- Thanks to the high dynamic electro mechanic drive system and “IRIS” safety 35% shorter cycle times on an average.

- Low Noise

- Genius Giant allows up to 55% less noise than other Heavy duty press brakes

The patented EVO-GO® modular hybrid servo drive is tailored to the special requirements of drives for CNC press brakes. All required components can be assembled using a modular design, ensuring optimal use of the installation space through a flexible layout and required oil volume here is only 60 % compared to conventional drives.

ADVANTAGES:

The EVO-GO hybrid adapted to the special requirements of drives for CNC press brakes:

- Respect for the environment

- Energy saving*

- Speed*

- Reduced noise*

- Less maintenance

- Less waste*

- Extreme precision

- Repeatability

Dynamics with significant energy savings.this principle allows efficient operation without additional cooling.

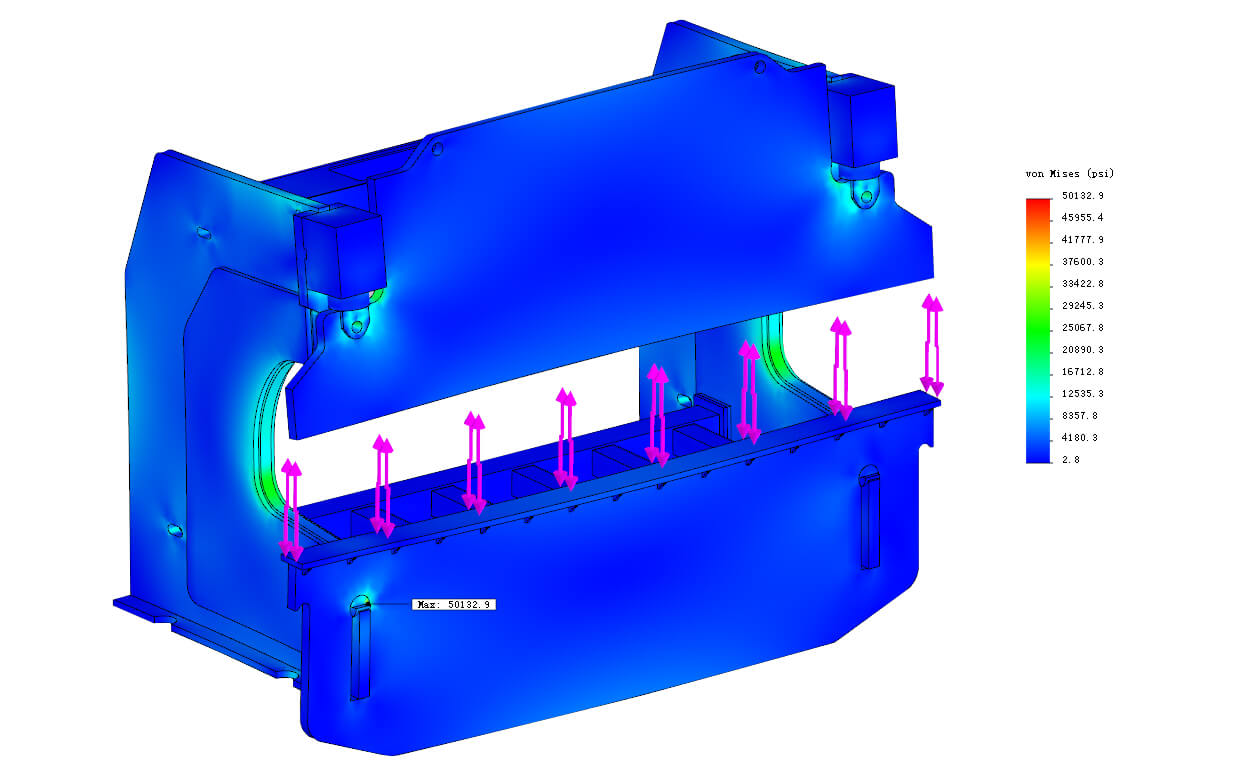

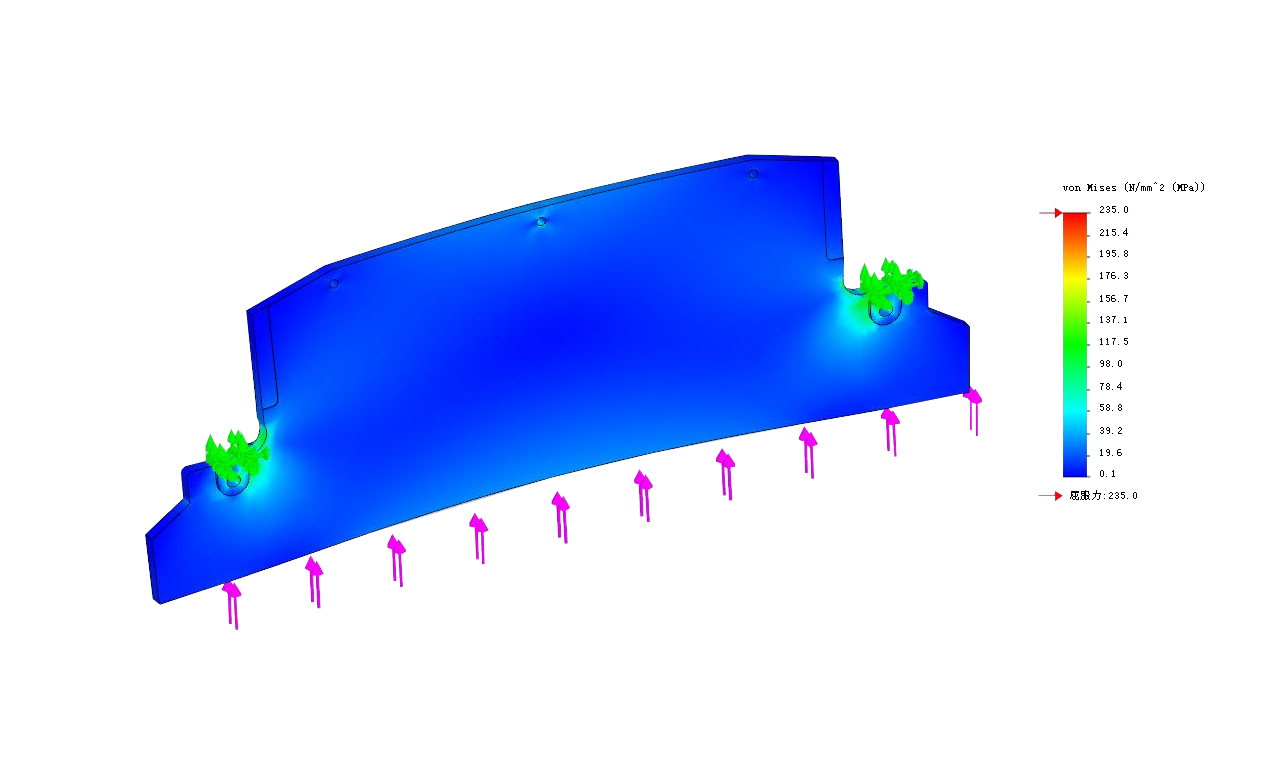

ACCURL have vast experience with R&D and designing components to very tight tolerances with SOLIDWORKS 3D CAD modelling techniques.

The design and analysis experiences of computer aided engineering (CAE) used in the heavy industry is novel for conventional company before prepare going to execute the fourth industrial revolution.

STRESS ANALYSIS & FINITE ELEMENT ANALYSIS:

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press brake and laser cutting machine frames.

ACCURL engineers are competent in designing with first principle calculations for the CNC press brake and laser cutting machine

Optional with Press brake accessories: production traceability & barcode reader:

The Custom Made Tooling also include bottom tools with an adjustable opening width. The opening width (V-opening) can be adjusted as necessary. The primary advantage offered by these adjustable bottom tools is that the bottom tool does not need to be changed with the sheet thickness: the opening width can simply be adjusted as necessary. This results in substantial time savings espe-cially when large dimensions are involved.

The WILA range of products includes two models of adjustable bottom tools:

- Automatically adjustable bottom tool, type MVM, designed for bending precision sheet material

- Manually adjustable bottom tool, type Multi-V, designed for bending plate material

Wila Multi-V-Matic (Mvm)

Main Features Are:

- Patented adjustable die system.

- Maximum load up to 3000 kN/m.

- 60° bending angle to manage springback.

- Modular structure in length from 1 to 12 meters.

- Pneumatic system for easy adjustment of "V" opening.

- Built with high resistance steels and induction-hardened base.

Pre-bend & flattening in the same tool.

Acts as a tool holder for OZU tools.

MVM Type I-1.

Interested in Metalworking Solutions?

Get Free Quote

Pricing, Technical Data & More

Is this the right Machine for Your Goals and Operations? Get a Guide to Help You Decide