When deciding on a press brake for your business, one of the most important considerations is whether to get a CNC hydraulic press brake or a servo-electric press brake.

That’s why we’ve created this guide to Hydraulic Press and Servo differences and similarities. Keep reading to learn about both options, how they work, and compare essentials like speed, precision, and longevity.

Overview of Hydraulic Press Brake and Servo Electric Press Brake

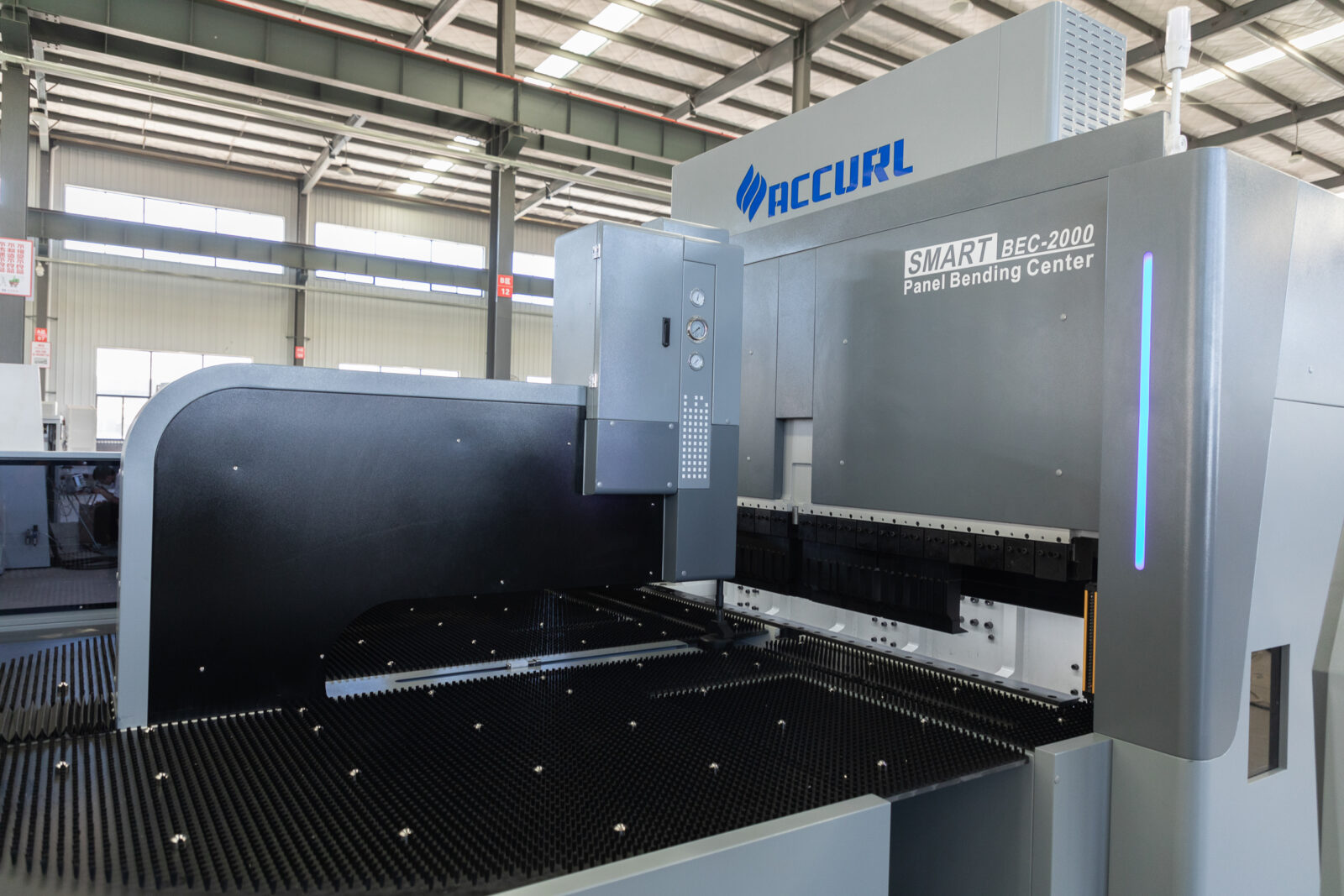

Both types of press brakes provide the same type of service: bending metal materials into specific shapes required in various metal fabrication operations. However, they do it differently due to several distinct differences.

While an electric servo press brake uses electricity to power servo motors that produce the movement and bend the material, hydraulic press brakes use oil and hydraulic cylinders to do so. In addition, there are also hybrid servo electric press brake options that combine electricity and hydraulics.

Both machines can utilize CNC controllers, which means you can use a computer to set the specifications for your bends, making it easier and faster to control. Because of that, the main differences come from the other working principles.

Working Principles of Hydraulic Press Brakes and Servo Electric Press Brakes

So, what are the exact working principles of hydraulic press brakes and servo-electric press brakes?

Hydraulic Press Brakes

With hydraulic press brakes, hydraulic fluid is used to generate force using cylindrical hydraulics. The operator will start the process and create pressure that drives hydraulic fluid through hydraulic pumps. The fluid activates the cylinders which, in turn, move the ram and apply the force to the bend.

While this process requires significantly less energy (around half the amount) than the similar process of servo-electric options, it consumes power even while it’s not working. Because of this, they actually use more energy than electro-servo options while also consuming oil and producing a loud sound. However, we’ll cover other differences in speed, durability, and precision later.

Servo Electric Press Brake

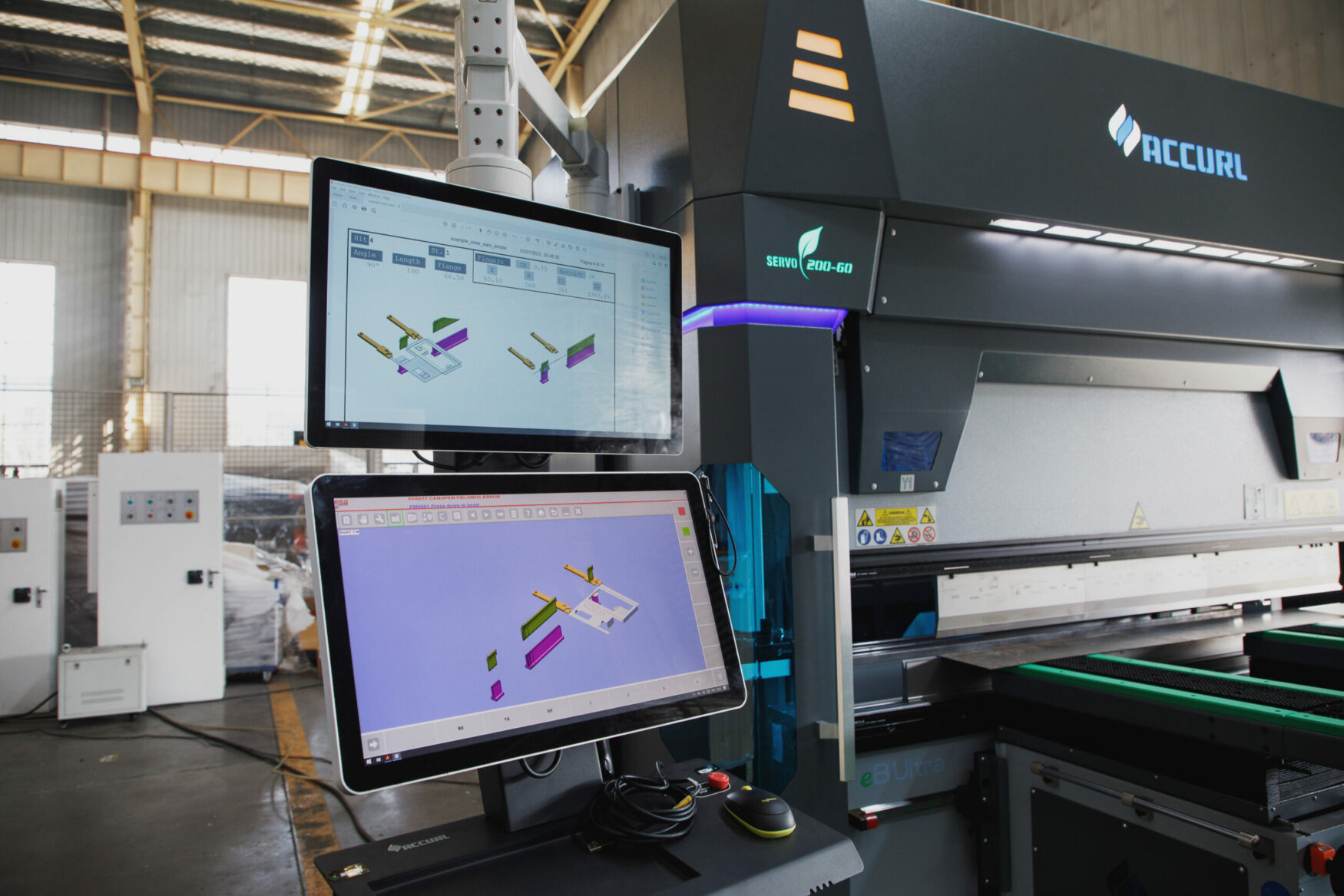

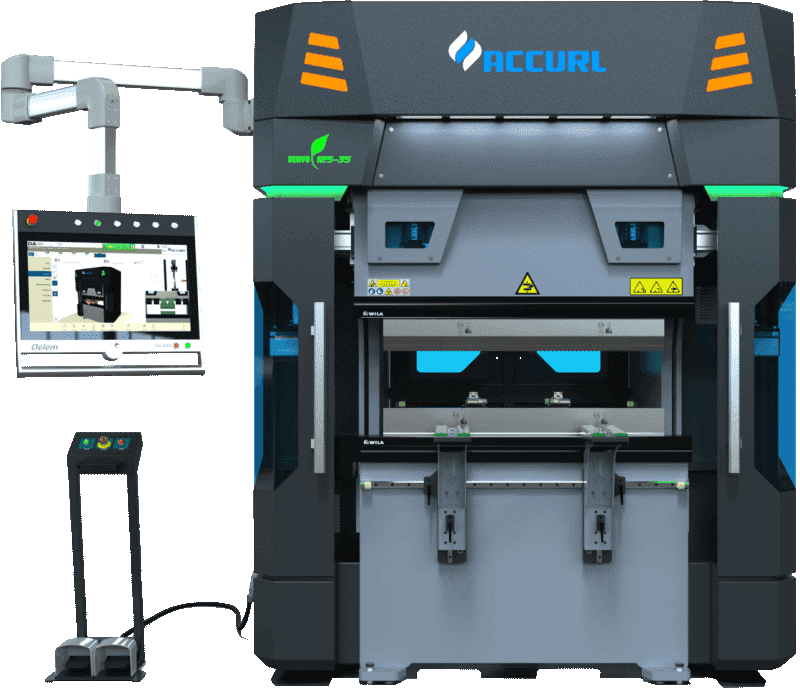

These electric press brake options utilize servo motors and ball screws or belt systems for precise bending. Servo motors apply pressure force with a transfer of belt and pulleys or ball screws, applying accurate bending force required for the material and thickness. The rotary motion is translated into linear motion perfect for bending.

For example, the Accurl Electrical Press Brake eB Ultra offers an incredible bending force range of 25 to 125 tons and provides up to 80% energy savings compared to hydraulic press brakes and other, less advanced electro-servo models.

Hydraulic Press and Servo Difference in Speed, Precision, and More

So, now that you understand the working principles behind each option, how do they translate into meaningful differences for your operation like efficiency, precision, and longevity? Read on to find out!

Speed and Efficiency

When it comes to efficiency, it’s not only the fact that servo-electric press brakes are more energy efficient. In addition, they are generally faster as well. While hydraulic press machines often have a faster approach speed, that’s where its advantage ends.

With easier operation even when compared to CNC hydraulic press brakes, faster acceleration and deceleration, and higher bending speed, an electric servo press brake can optimize output and amplify productivity for any operation.

In fact, advanced machines like the Accurl eB Ultra Press Brake offer high-dynamic mechanic drive systems that promote an average 55% shorter cycle times. That means higher output and higher revenue potential for various metal fabrication industries. Not only that, they combine this speed with our next comparison: precision and accuracy.

Precision and Accuracy

While both types of press brakes will be very accurate with single bends, the Hydraulic Press and Servo difference is bigger when it comes to repeatability. Still, even for single bends, electric press brakes are often accurate within a single degree or 0.000079 inches while hydraulic presses are accurate within 0.0004 inches.

Servo-electric press brakes have extreme precision and repeatability, producing uniform results even with complex bend angles and depths. That’s because of the closed-loop control systems that maintain precision throughout daily, weekly, and monthly operations.

While the accuracy and precision might not seem to make that much of a difference, especially when both CNC hydraulic press brake options and servo-electric press brake models are accurate within a fraction of an inch, this is a critical consideration for certain industries where precision is paramount. For example, when creating aerospace or medical parts, a servo-electric press brake could be essential.

Maintenance and Longevity

Finally, the different working principles between electric and hydraulic press brakes make a good deal of difference when it comes to maintenance, repairs, and longevity. This is important as maintenance takes time and money, thereby impeding operations and profitability.

Hydraulic press brakes, due to their oil consumption and complex combination of pumps, valves, and hoses, require more frequent cleaning and maintenance. Additionally, they break down more often, which means higher repair costs and more downtime.

On the other hand, servo-electric press brakes have fewer moving parts that can break down. This means less maintenance as well as a longer machine life. This is especially important for high-volume metal fabrication operations.

Plus, with makers like Accurl, you’ll get ongoing support for your servo electrical press brake. And if you want some of the benefits of hydraulic combined with the quiet, lasting, and precision bending of a press brake, we offer the H-Brake Hydrid Press Brake Euromaster with rapid ram speed, 65% less energy consumption, 70% less noise, and 35% shorter cycle times.

Conclusion

As you can see, the hydraulic press and servo difference when it comes to press brakes is critical. That’s because servo-electric press brakes are more precise, require less maintenance, last longer, are quieter, consume less energy, and are faster. So, all that’s left is to compare different prices and models to find the perfect option for your business.

Accurl offers over 30 years of experience crafting the most advanced press brakes with powerful, long-lasting motors, low energy consumption, and the most precise results required by even the strictest industries. Click here to request a quote on a servo-electric press brake or hybrid press brake model.