An industrial press brake machine can upgrade virtually any metal fabrication operation, adding a range of advantages that ensure consistent results, productive processes, and cost-effective production.

So, what exactly are these sheet metal fabrication advantages that a press brake can provide? Keep reading to learn how a press brake can help you enhance precision, promote flexibility, boost efficiency, and optimize resources and your bottom line.

Before we look at press brake benefits for fabrication, what exactly is a press brake?

Press Brake Overview

A press brake is a machine that can bend sheet metal and metal plates. You can perform accurate and pre-determined bends by clamping the sheet or plate between the tool and the die. This makes them a valuable addition to various metal fabrication processes for industries like aerospace, construction, consumer goods, automotive, medical equipment, and more.

While manual press brake machines are still used in smaller operations, many of the most impactful advantages of using press brakes come with the more modern choice: CNC press brake machines.

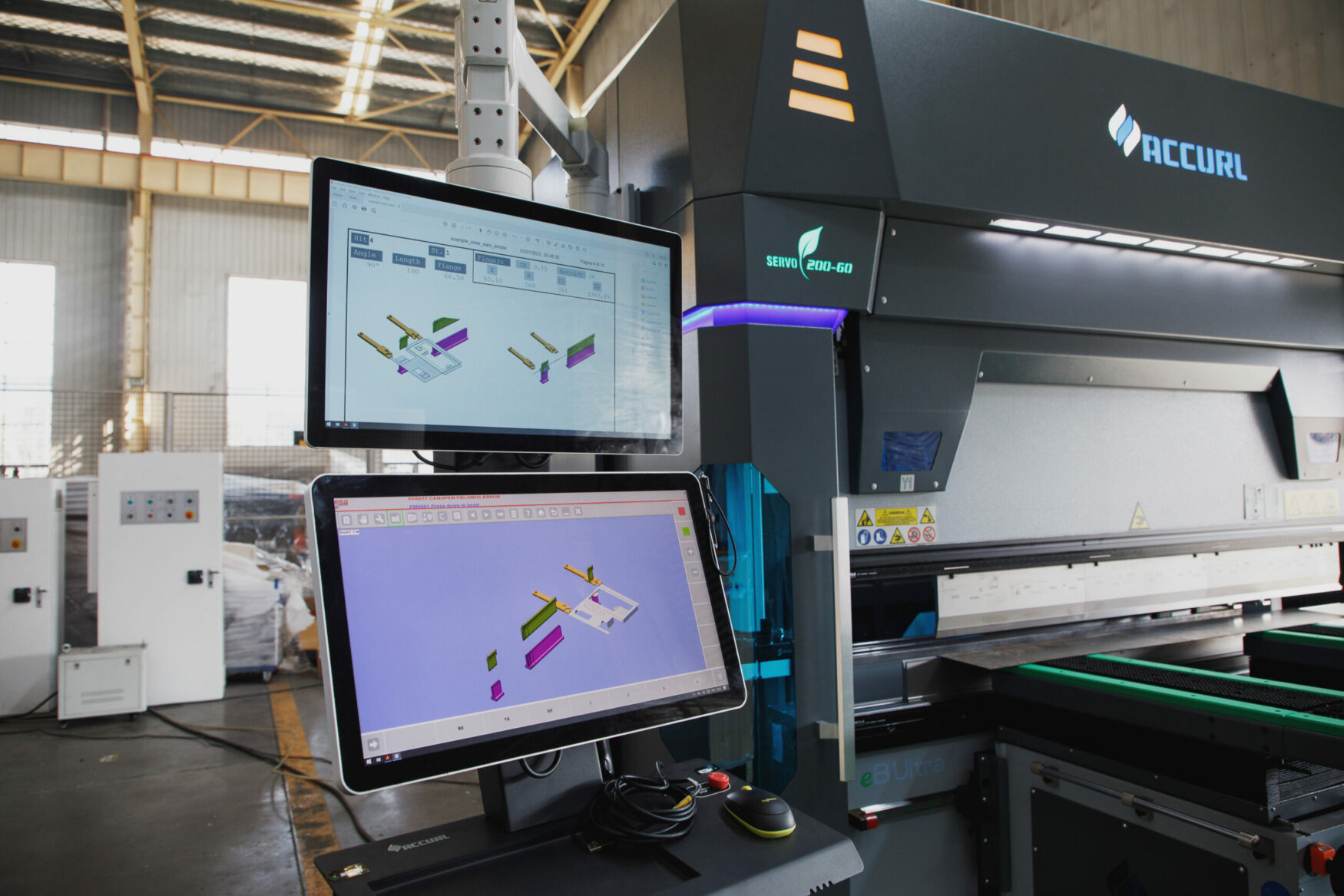

Computer Numerical Control (CNC) press brakes use a computer to control the machine, allowing for simpler, faster operation and more precise bends. The best and most advanced CNC press brakes offer additional benefits as well.

For example, the Accurl Electrical Press Brake eB Ultra offers exceptional high repeating accuracy, 80% lower consumption than hydraulic brakes, and 70% less noise than competitors. Plus the dual-drive hybrid servo system offers a bending force range of 25 to 125 tons!

So, if you have an operation that requires bending sheet metal, then you might consider CNC Press Brakes. Not convinced yet? Keep reading to see the awesome press brake for sheet metal fabrication advantages.

Press Brake Benefits for Fabrication

There are tons of press brake benefits in metalworking and fabrication, but they generally fall into 4 main categories: precision, versatility, efficiency, cost-effectiveness.

Precision Bending

Precise bends are a critical aspect of optimal metal fabrication. That’s because precise bends mean more uniform outputs, happier clients, and value even for the strictest industries like aerospace or medical equipment manufacturing. Precision bending with press brakes keeps getting better too.

Manual press brakes are quite accurate already, allowing the operator to set the preferred bending parameters. However, CNC machines are even more accurate with computer control that determines accurate bends within a fraction of a millimeter.

Additionally, they can create complex bends or multiple bends in the same metal material. That makes them valuable for furniture manufacturing, signage industries, and more. Plus, with fast and easy control, you can produce these precise bends on one machine instead of wasting time switching the parameters for every single bend.

The Accurl eB Ultra Press Brake bending machine doesn’t just make precise bends. It does so with unmatched repeatability. In fact, even though it offers high-speed bending, the precision is repeatable to an outstanding 0.0001 millimeters.

Versatility and Flexibility

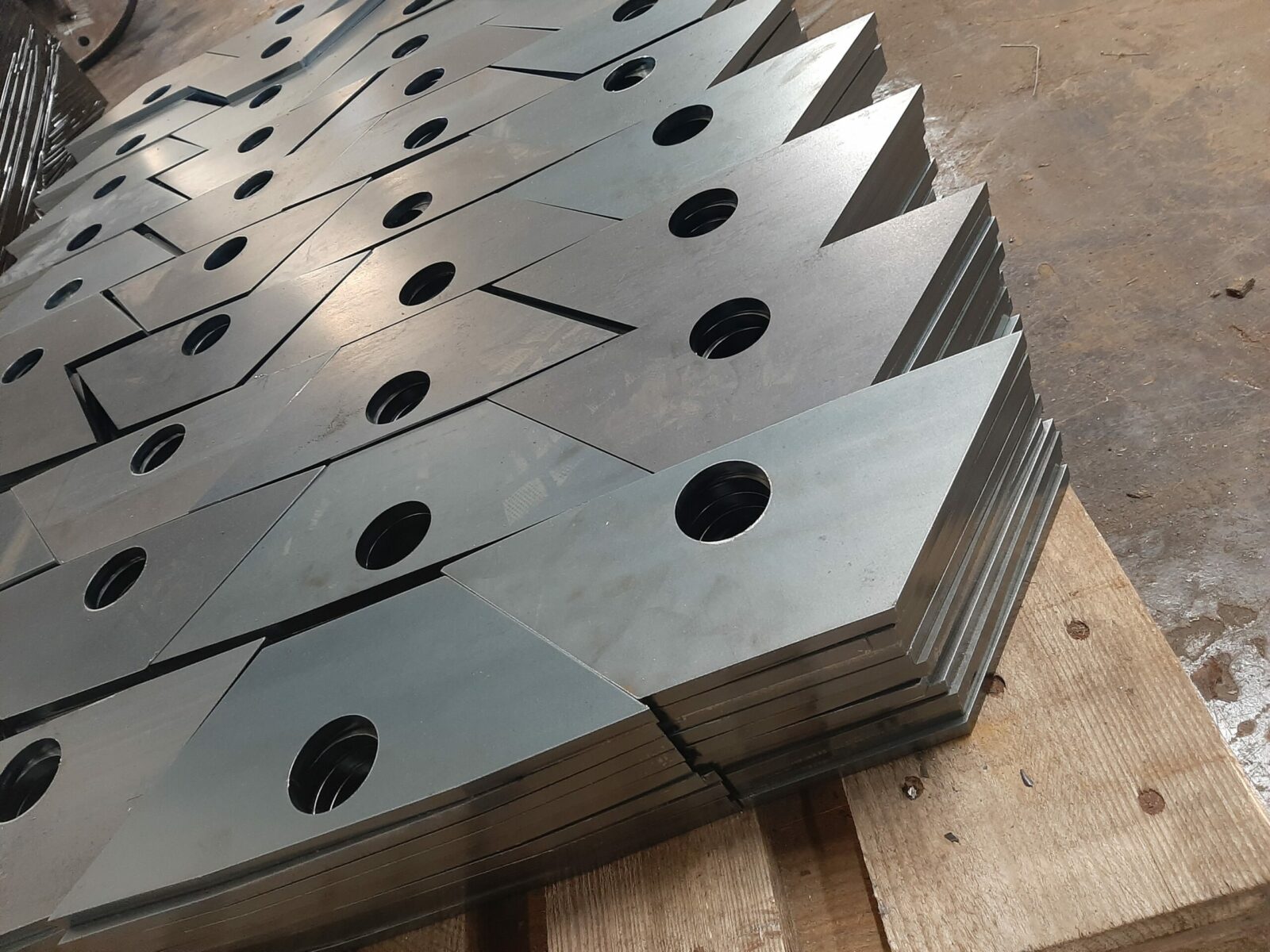

Press brakes are incredibly versatile, handling a wide variety of materials and thicknesses. While it might depend on the specific model you get, press brakes can work with mild steel, stainless steel, aluminum, copper, brass, and more.

Some will even be able to bend iron or precious metals, but those are likely specialized machines. This is one of the undervalued press brake benefits for fabrication considering it’s the reason they are so useful for so many industries.

For example, these press brake benefits in metalworking are used for virtually any industry that bends metal including aerospace, automotive, construction, agriculture, electrical equipment, HVAC systems, furniture making, consumer appliances, medical, oil and energy, advertising, railways, telecommunication, commercial kitchen equipment, art, defense, laboratory gear, and more.

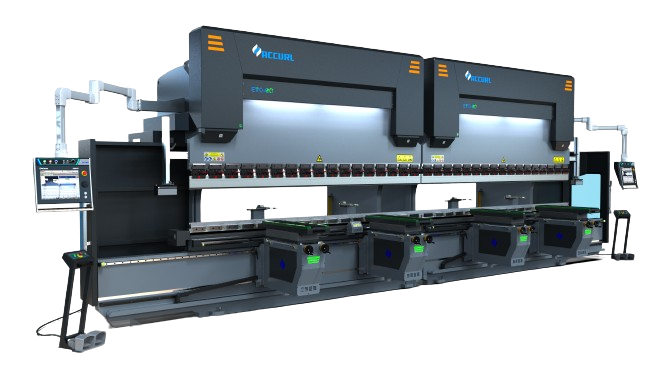

Plus, options like the Accurl Tandem Press Brake Genius Pro Series are incredibly flexible and 100% tailored to your specific needs. Using a tandem of 2, 3, 4, or more machines, you can optimize operations with versatility for virtually any material, bend type, and output level.

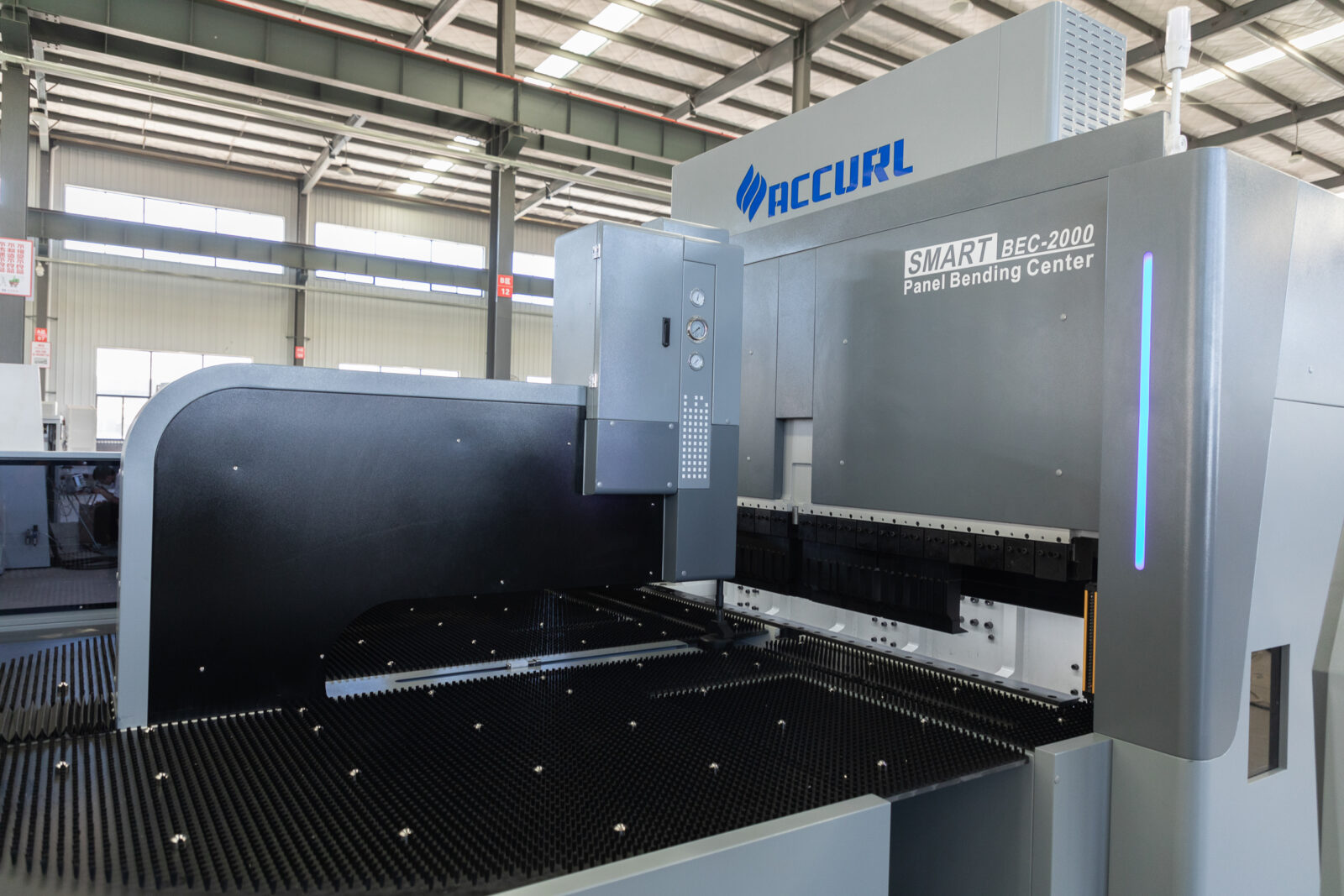

Efficiency and Productivity

This is one of the most important press brake benefits for fabrication because it means a higher output, raising your bottom line. They are easy to operate, which shortens loading and parameter times. Then, the powerful machine makes the bends swiftly, increasing output and optimizing your operations.

Plus, they do all this while maintaining safety and precision, making them an invaluable addition to many metal fabrication operations. If you don’t care about the other advantages of using press brakes, at least consider the impact on your profits.

Even better, some options like the Accurl Hybrid Press Brake Euromaster are also energy efficient, reducing energy consumption by as much as 75%. That means they directly save you both time and money.

This machine also uses a high dynamic electro mechanic drive system and “IRIS” safety with specialized cameras. The result is 45% shorter cycle times and 70% less noise than other press brake and metal bending machines.

Cost-effectiveness and Resource Optimization

Press brakes offer precise bends and versatility which means you’ll waste less materials, saving you money. Plus, almost every one of the press brake benefits in metalworking promotes cost-effectiveness.

You can save money or increase profits with various features whether you are increasing productivity with efficient operations, eliminating the need for more machines by using a flexible press brake option, creating happier clients with precise bends, or making happier employees with a safer workplace and easier operation.

So, if you’re not already using a press brake machine for your metalworking operation, it’s probably time to start. Just make sure you go with a reputable vendor and a machine model that is equipped for your output levels, bend types, materials and thicknesses, and specific usage volume.

Conclusion

As you can see, there are tons of press brake sheet metal fabrication advantages including precision, efficiency, cost-effectiveness, safety, energy efficiency, resource optimization, versatility, and more.

Ready to add a state-of-the-art press brake to your operation? Click here to get a free quote on Accurl’s press brakmachines and we’ll help you determine the best option for your specific needs. That way, you guarantee higher profitability.