Laser-cutting machines are valuable assets that offer distinct advantages and precision cutting for industries including automotive, electronic devices, pharmaceutical equipment, aerospace, construction, and more.

So, what are these laser-cutting benefits? Keep reading to learn how an industrial laser cutter can optimize precision and accuracy, meet diverse manufacturing needs, boost efficiency, improve safety, and promote environmentally friendly operations.

But first, what are laser cutting machines and what are they used for?

Industrial Laser Cutting Overview

Laser-cutting machines are cutting-edge tools that leverage a high-powered laser to cut through materials including various metals like stainless steel, aluminum, and titanium as well as other materials including plastics, acrylic, and wood.

By using a powerful beam of light to cut into the material, these machines preserve the integrity of the cutting surface while precisely cutting even the most complex shapes. That’s why there are so many industrial applications of laser cutters like the:

- Automotive industry for metal components, chassis parts, body panels, and more

- Aerospace sector for fabricating aircraft structural, engine, and interior components

- Medical space to create precise equipment used in hospitals and laboratories

- Signage industry used for creating acrylic, metal, and plastic signs

- Electronics sector for creating intricate cuts required by cutting-edge tools

- Furniture Manufacturing space as well as other consumer goods

The reason that these machines are used for such a wide variety of industrial operations is because of all the powerful laser-cutting technology advantages they offer.

Industrial Laser Cutting Advantages

There are dozens of laser cutting benefits, but they generally fall into a few categories: precision and accuracy, versatility and flexibility, efficiency and productivity, safety, and environmental benefits.

Precision and Accuracy

Industrial laser-cutting machines utilize the most cutting-edge technology to create precise cuts. That’s because the high-powered laser is so concentrated to seamlessly cut through materials, thick and thin.

So, why is precision important? It means better quality control and even the ability to produce accurate results required by medical gear, aircraft parts, and other critical applications. Not only that, but it also doesn’t compromise the strength and integrity of the cut material, making safer parts for automobiles, aircraft, and medical devices.

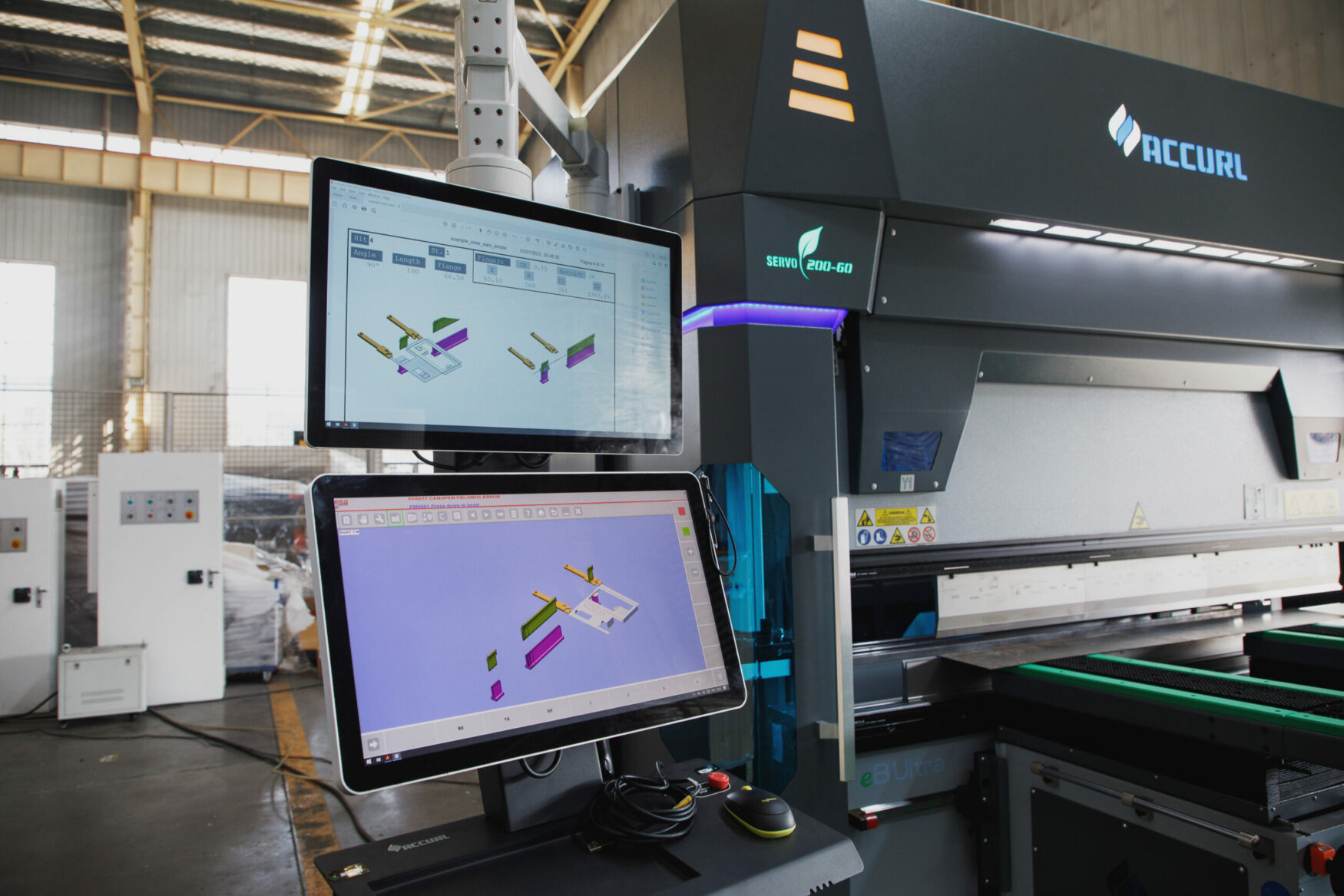

The best laser cutting machines for industrial operations are precise within .05mm, like the Accurl MasterLine Series designed for sheet laser cutting. These advanced machines aren’t just extremely accurate but also utilize CNC controllers for easier operation.

Versatility and Flexibility

You’ve already seen how many industrial applications of laser cutters there are, but flexibility and versatility are truly one of the most important industrial laser cutting advantages. Many of them machines can cut through a wide variety of different materials including:

- Stainless Steel

- Mild Steel (Carbon Steel)

- Aluminum

- Brass

- Copper

- Galvanized Steel

- Titanium

- Nickel Alloys

- Precious Metals like Silver, Gold, and Platinum

- Acrylic (Plexiglass)

- Wood

- Plastics like POM, ABS, and polycarbonate

There are many more plastics and other materials that these machines can cut, but their versatility also extends to various thicknesses. That means you’ll be able to cut through both thick and thin materials whether thick wood, sheet metal, or large PVC.

Finally, combined with top-of-the-line precision, industrial laser cutting machines can create complex shapes, making them useful additions to virtually any industrial use.

Efficiency and Productivity

Another one of the industrial laser cutting advantages is the unmatched efficiency they offer. By leveraging a high-powered laser beam, you can swiftly create unique and complex cuts. Plus, with CNC-operated laser cutters, your operators have an easier job creating the exact results you need.

The result is unparalleled productivity with a higher output in a shorter amount of time than other manual cutting methods. This can instantly elevate your bottom line while streamlining the creation of materials for your clients.

In fact, the Accurl MasterLine series offers a rapid max XY speed of 160 m/min with 20 m/s² acceleration. That’s extremely fast, allowing for more work to be done in the day while still producing the highest possible quality results.

Safety

With protection systems in place and a concentrated laser within a sealed area, these machines are incredibly safe. That means there’s a near-zero chance of workers being burned by the laser.

Plus, the best machines have advanced cooling systems to prevent overheating or the risk of injury when handling the produced material. That means fewer injuries from tool-to-material or operator-to-material interactions.

These machines don’t just offer safety for your operators, though. They also promote safety for the materials themselves by creating precise cuts that never compromise the strength of the material. That means no contamination and stronger materials for your industrial process.

Finally, CNC controls allow for maximum safety with easy inputs and automatic cut-off should an accident happen. Plus, the operator will be able to quickly shut down the machine should something go wrong.

Environmental Benefits

One often undersold industrial laser cutting benefit is the environmental advantages. The laser-cutting process preserves materials and reduces the amount of wasted components. That means less waste which doesn’t just improve the environment but also helps you raise your bottom line.

Not only that but compared with mechanical saws and tools, these machines use much less energy. Again, this doesn’t just benefit the Earth but also helps you save money during operations.

Additionally, these machines can improve the environment of your operations as well. With lower noise output and a single machine that cuts through various materials, thicknesses, and shapes, you can improve the atmosphere of the workplace.

Finally, these eco-friendly fiber laser cutting machines last for years, meaning less waste and machine turnover that benefits the environment, your workers, and your profitability.

Conclusion

As you can see there are various industrial laser-cutting advantages for your operations, workers, and the planet. With state-of-the-art laser cutting technology advantages like efficiency, precision, safety, and productivity, you can improve operations and generate faster, stronger, and more accurate results.

However, there’s a huge difference between the laser cutting benefits you’ll obtain with a high-quality machine and a cheaper model. Accurl offers 35 years of expertise and offers a variety of top-notch laser-cutting machines like our MasterLine series. Click here to contact us to learn more about our advanced tools for your industrial operation.