Compact fiber laser cutting machines combine the power, efficiency, and precision of larger-scale laser cutting machines, with flexibility, versatility, and a small footprint. Because of that, they are the perfect options for small-scale manufacturing and prototyping, but are they the perfect option for your operation?

Keep reading to find out by delving into our complete guide to compact fiber laser cutting machines, the advantages, applications, cost-effectiveness, and other factors.

Overview of Compact Laser Cutting Machines

In general, a laser cutting machine leverages a high-powered laser to swiftly make precise cuts in various materials including various metals, plastic, and wood. Many industrial laser cutting machines, though, are large and inconvenient for smaller manufacturing and prototyping operations.

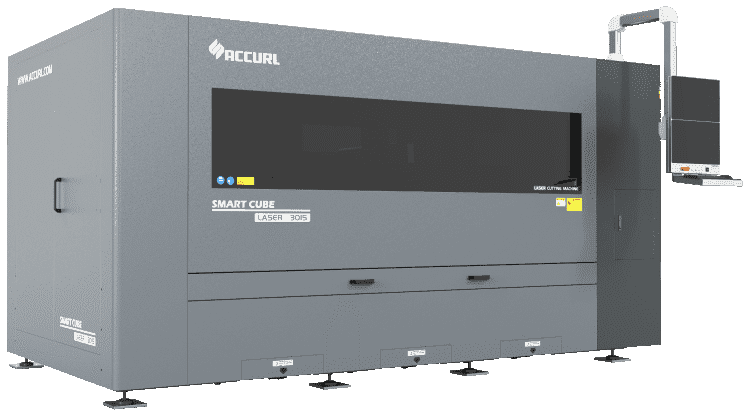

That’s why compact laser cutting machines can be a great alternative to larger options. They offer compact power, a smaller footprint, and precision for even the most intricate cuts. While there are various types of compact laser cutter machines, fiber laser cutting machines offer unmatched versatility, precision, and power.

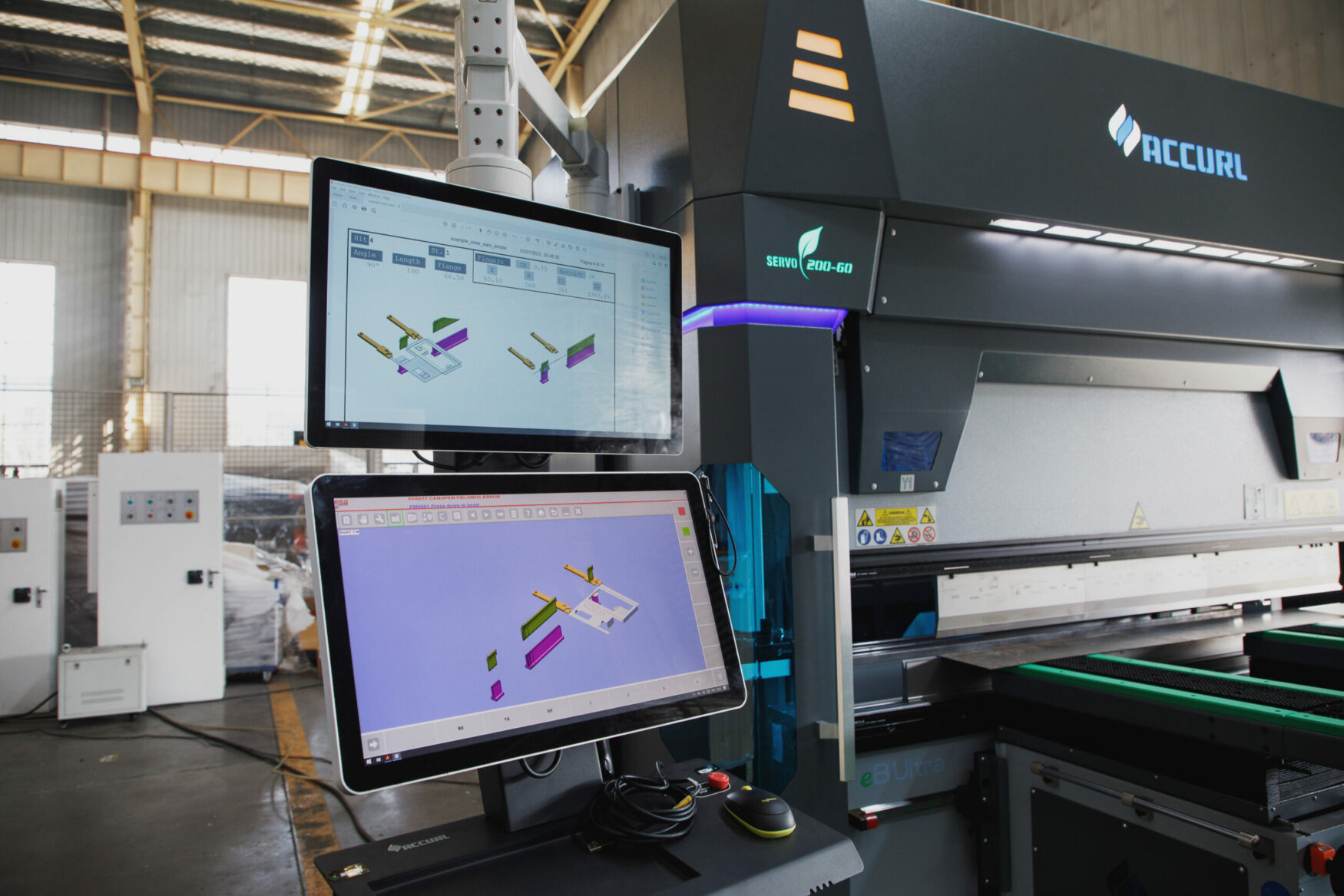

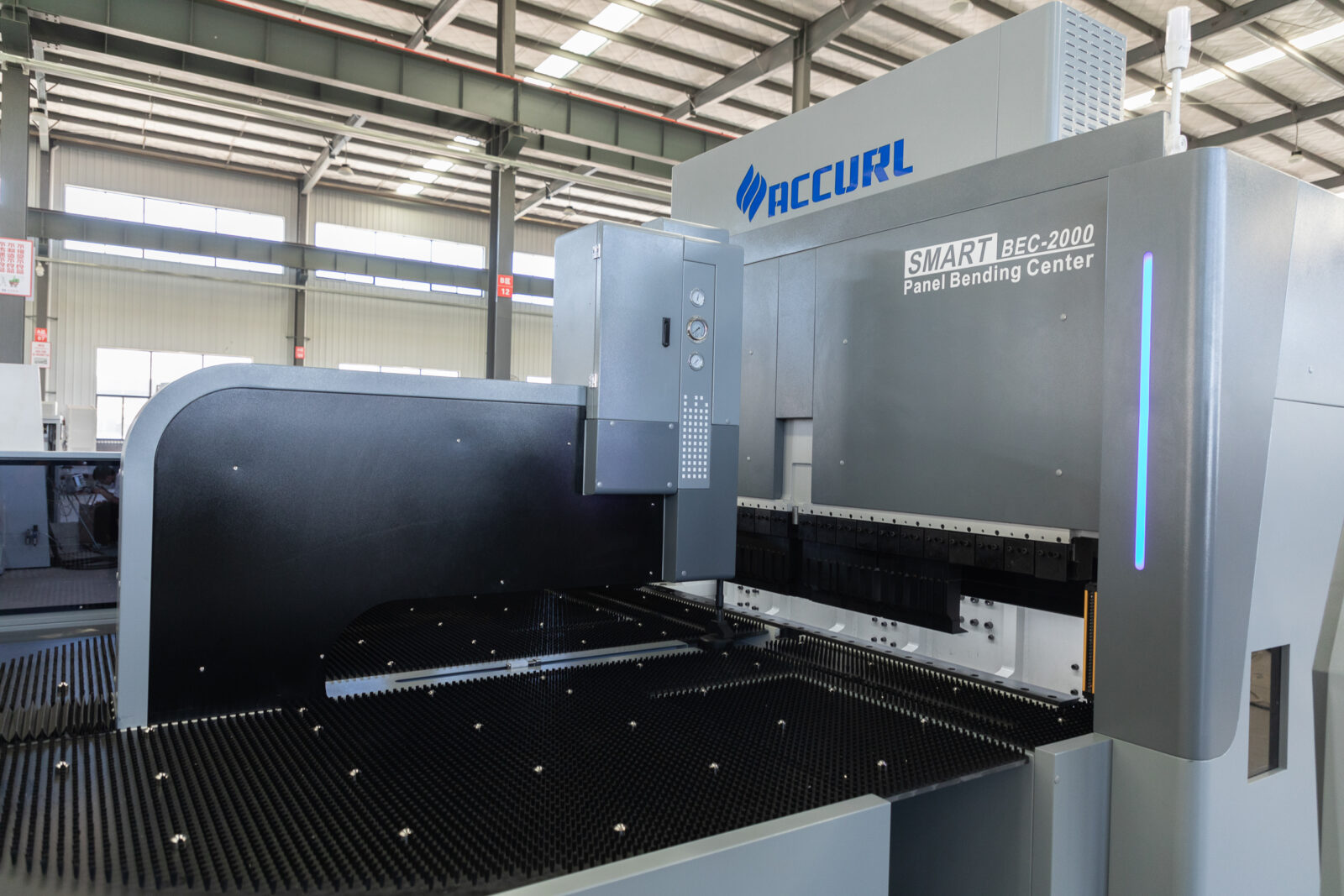

For example, the Accurl Compact Laser Cutting SMART Cube maximizes performance, precision, and efficiency while minimizing machine footprint, perfect for small operations or even large ones where floor space is limited. The retractable cutting table not only allows for even more compact storage while not in use, but also simplifies loading and accelerates efficiency.

Advantages of Compact Fiber Laser Cutting Machines

We’ve already touched on some of the benefits of compact fiber laser cutting machines, but to truly determine whether they are a good choice for your needs it’s important to delve deep into each advantage including compact design, energy efficiency, versatility, precision, and speed.

Save Space

The compact design of a mini CNC laser metal cutting machine saves plenty of space without compromising cut quality. The CNC fiber laser operation is compact with computer controlled operation that simplifies the process as well. This makes them a perfect option for small-batch production, prototyping, and other small business applications.

Boost Energy Effeciency

While energy efficiency might not be your top priority, smaller fiber laser cutting machines tend to use less energy than their larger siblings. That means lower costs that, in turn, promote higher profits. Not only that, but fiber laser cutting machines in general make precise cuts that drastically reduce wasted materials.

Promote Versatility

The compact design combined with CNC operation and a powerful fiber laser makes these types of machines incredibly versatile. Not only are they useful for a variety of different applications and industries, as we’ll demonstrate later, but they can be used for various materials, cut angles, and designs within the same operation.

Plus, they can work alongside and harmonize with other machinery like press brakes or compact laser welding and cleaning systems.

Achieve Unmatched Precision

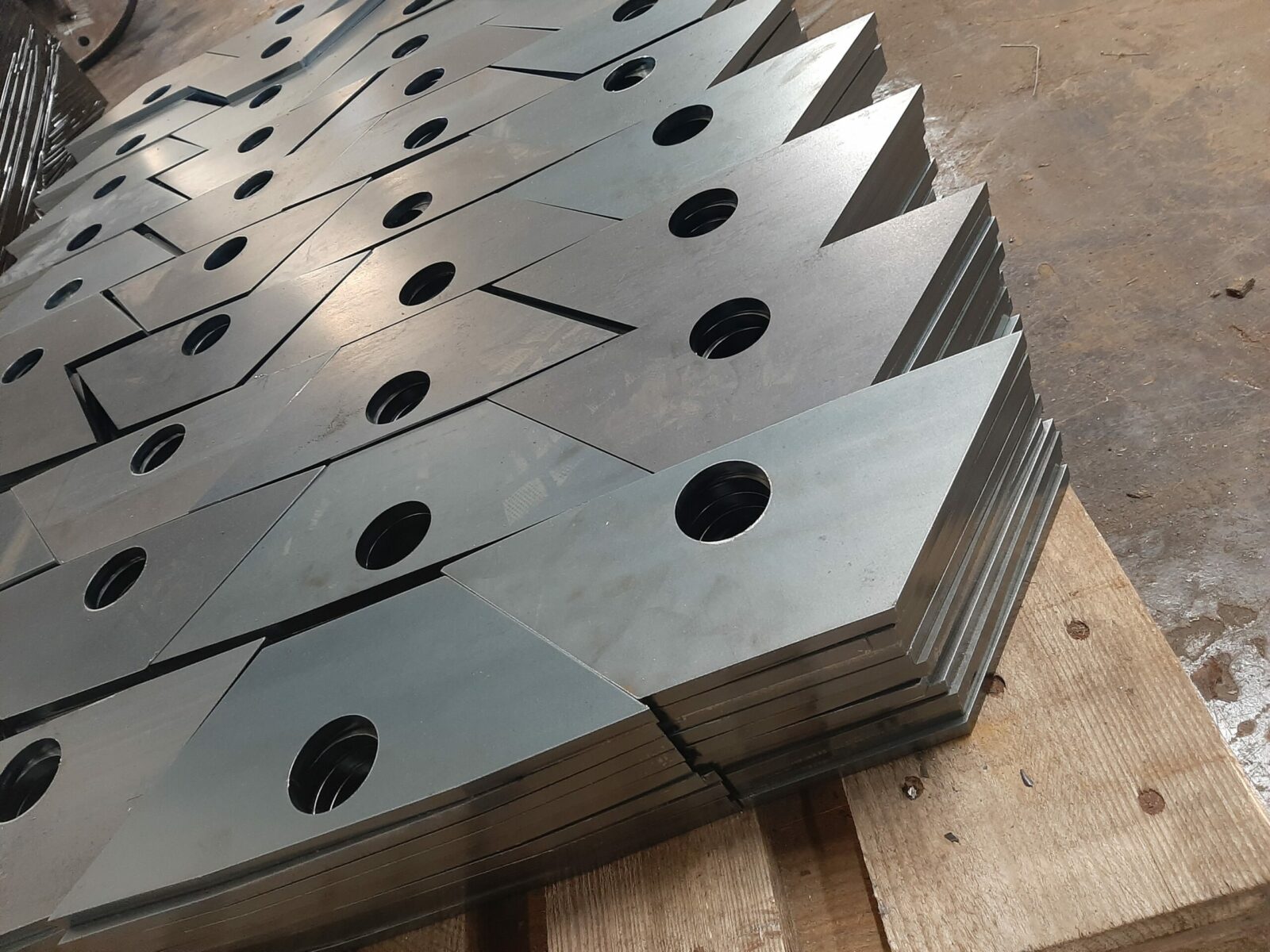

Compact laser cutting machines that use fiber lasers and are made by trustworthy providers are exceptionally precise. They can make intricate cuts without compromising the integrity of the material, perfect for any operation. As mentioned earlier, this precision can not only help you achieve better cutting results and output quality, but can also reduce material waste, instantly saving you and your business money.

Accelerate Output

A fiber laser cutting machine, even when packed into a compact machine, uses a powerful laser that rapidly makes precise cuts. That means higher productivity with efficiency that can scale with your operations, making them the perfect choice for business owners and operators who want to reach more ambitious goals.

Compact Fiber Laser Cutting Machine Applications in Small-Scale Manufacturing

Compact fiber laser cutting machines are exceptional tools for a variety of different industries and applications including:

- Custom part manufacturing, making parts for a variety of consumer goods, vehicles, construction projects, and more.

- Electronics with intricate designs and unmatched precision that produces uniform results.

- Jewlery making with the ability to create precise cuts on even the smallest designs, especially with top-of-the-line mini laser cutting and engraving machine options.

- Medical devices that require extreme precision for compliance, safety, and effectiveness

- Metal fabrication offering rapid cutting in a wide variety of metal materials including steel, copper, and more.

- Much more!

Cost-Effectiveness and Return on Investment for Compact Laser Cutting Machines

When selecting a new machine for your small-scale manufacturing or prototyping business, the main consideration you probably make is whether it can deliver a return on investment.

In most cases, compact fiber laser cutting machines can do exactly that quite quickly. Why? Because they immediately start saving you money on your energy bills while producing higher quality goods and delivering a higher per day output.

Not only that, but they also cut down on material waste and many options, particularly mini CNC laser metal cutting machine models like the Accurl SMART Cube, require less training for safe, effective, and reliable operation.

It’s true that these machines aren’t cheap, but when you consider their outstanding durability, versatility, precision, efficiency, and other factors, the value to your operation more than makes up the cost of the machine to begin with.

That means an ROI in less time while also promoting less stress for you and your team due to the powerful results that these machines can offer.

Choosing the Right Compact Fiber Laser Cutting Machine

So, how do you choose the best laser cutter for small business needs? Well, there are several considerations to make including power, cutting area, software capability, and manufacturer.

Power

The power you need will depend on the materials you need to cut as well as the speed with which you need to cut them. However, you don’t want to get a machine that’s barely powerful enough. Instead, try to leave some room for scalability as well as cutting that doesn’t put too much stress on the machine.

Cutting Area

Some compact laser cutting machines might be a little too compact depending on what you’re cutting. Make sure the machine you choose offers a cutting area that can accommodate any materials that you plan to cut. Again, make sure there’s a little extra space, just in case you need it in the future.

Software Capability

How easy is it to use? Does it have programmable options that boost efficiency? What about software safety features or additional settings? All of these are important considerations once you have narrowed down your options to a few compact laser cutting machines.

Manufacturer

One of the most important factors when selecting a compact fiber laser cutting machine is the manufacturer. Make sure you go with an experienced maker with decades of expertise, like Accurl. Additionally, see if they offer support and training options, repairs, and other above-and-beyond services.

Conclusion and Additional Resources

A compact fiber laser cutting machine is a valuable addition to various small-scale manufacturing and prototyping businesses in wide ranging industries like jewelry making, automotive, construction, and more. That’s because they combine powerful precision and efficiency with high output and a compact design that can fit into small spaces.

Need more information before deciding on a laser cutting machine? Check out these resources!

- Fiber laser cutting 6kW vs 12kW cs 15kW

- Laser cutting maintenance tips

- Guide to choosing the right fiber laser cutting machine maker

Ready to Learn More About Accurl’s Advanced Line of Laser Cutters?

Accurl offers powerful fiber laser cutting machines including a line of compact options that use the most advanced technology, easy CNC controls, unmatched precision, and energy efficient operations. Click here to contact us today to learn more!