While compact laser cutting machines are exceptional options for small-scale operations, they might need to have the high-volume output of larger manufacturing.

That’s where Large Format Laser Cutting Machines can make a huge difference, offering higher efficiency, power, and accuracy for even the busiest, largest, and most demanding operations. So, how do they work to perform these actions accurately and efficiently?

Keep reading to learn about the principles of Large Format Laser Cutting Machines including the science behind the laser cutting process, different components and systems, and more. But first, what exactly are large format laser cutting machines?

Introduction to Large Format Laser Cutting Machines

A larger format laser cutting machine and engraver is an enlarged version of a standard laser cutting machine, perfect for precisely cutting a wide variety of materials including metals, plastics, woods, and more.

So what is the advantage of a larger laser cutter? Here are a few:

- A larger work area is perfect for industries and operations that need to cut large pieces of metal or other materials.

- High-volume output allows for faster production, even for the largest manufacturing operations

- Quicker turnaround times with higher power and advanced systems that allow for even more efficiency

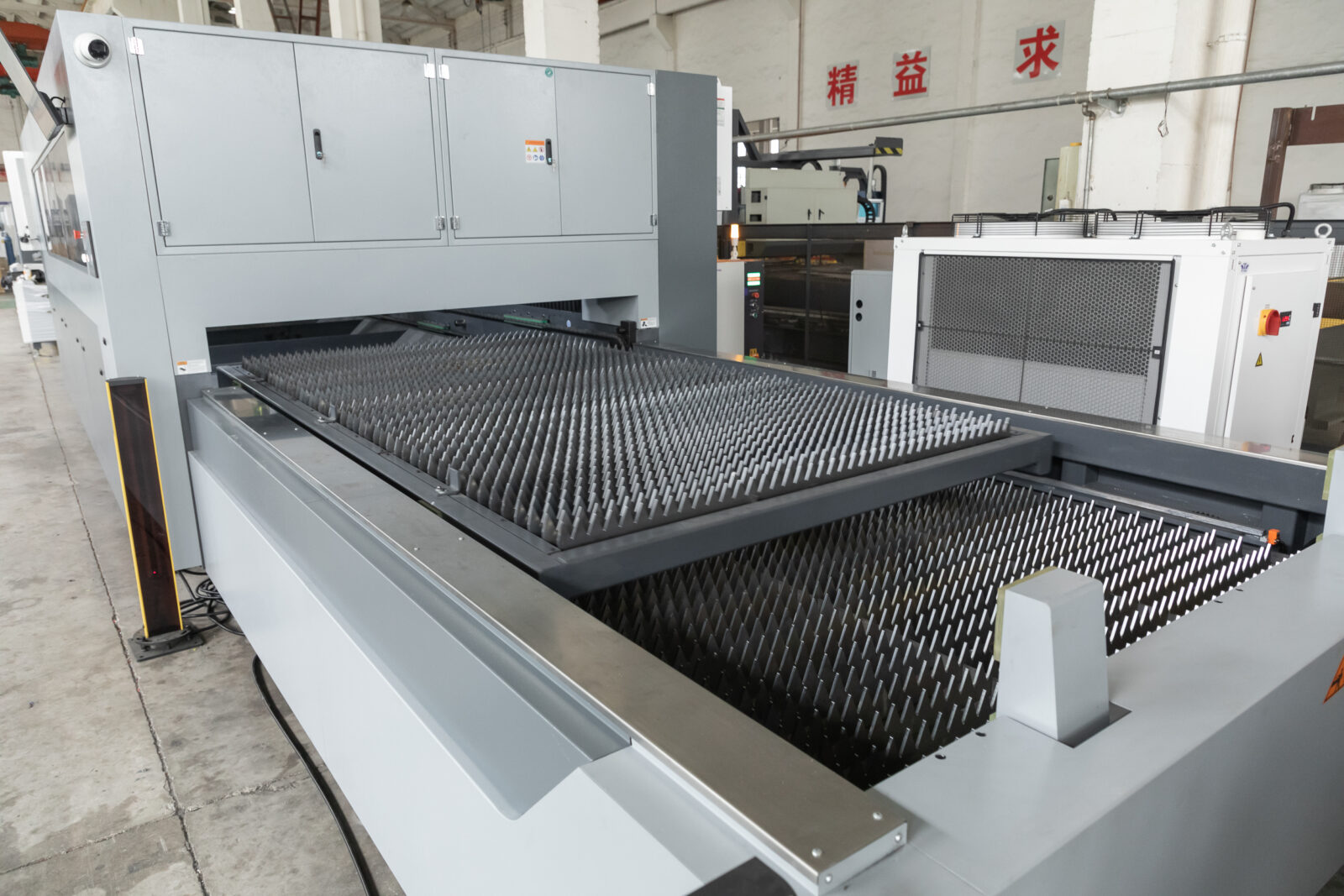

Not only that, but they are generally very dependable and durable, offering years of accurate cutting with only regular maintenance and minor repairs and replacements. Even better, many machines streamline the entire laser cutting process with built-in loading and offloading sections.

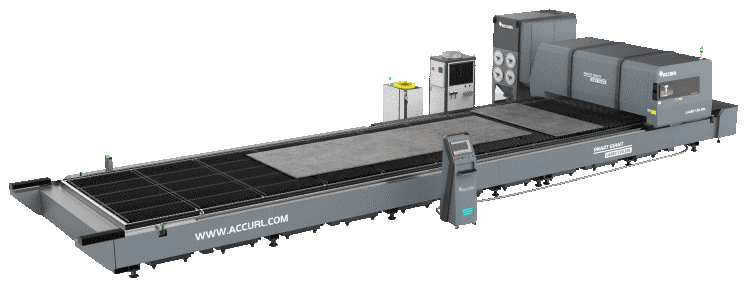

For example, the powerful Accurl Large-Format Laser Cutting SMART GIANT offers cutting, loading, and offloading simultaneously along with an expandable design for versatile use from 10 meters to 40 meters.

The dynamic, high-tech cutting head generates high power and allows for top-notch cutting performance around the clock. Despite all the advanced features, it’s also exceptionally easy to operate with simplified CNC controls and safety features.

Whether you choose this advanced Accurl system or other models the working principles of large format laser cutting machines are the same, starting with the science behind laser cutting.

The Science Behind Laser Cutting

Large format laser cutters, as the name suggests, leverage high-powered lasers to slice through various materials, including even thick and hard metals like steel. Focusing and amplifying the light beam makes it a powerful laser that travels through a nozzle containing a special lens.

As the heat of the highly focused laser hits the surface layer of the metal, the energy is converted into heat. This raises the metal to its melting point, thereby producing a narrow and highly accurate cut. The stronger the laser, the more quickly this process can be achieved and the more accurate the cut, with fewer imperfections.

To focus the laser in this way, several components and systems have to work together in harmony, not only allowing for the operator to control the laser but also to focus the laser and generate enough heat when it hits the material.

Components and Systems

So, what are the parts that allow for this magnificent cutting process? The most important to understand are the laser source, optics, CNC controller, motion system, and cutting bed.

Laser Source & Optics

The laser source depends on the type of laser, but for most large-format laser cutters a fiber laser is the source of power. Additionally, the laser source includes the optics which are the laser cutter head complete with the nozzle, focusing lens, and focus tracking system.

CNC Controller

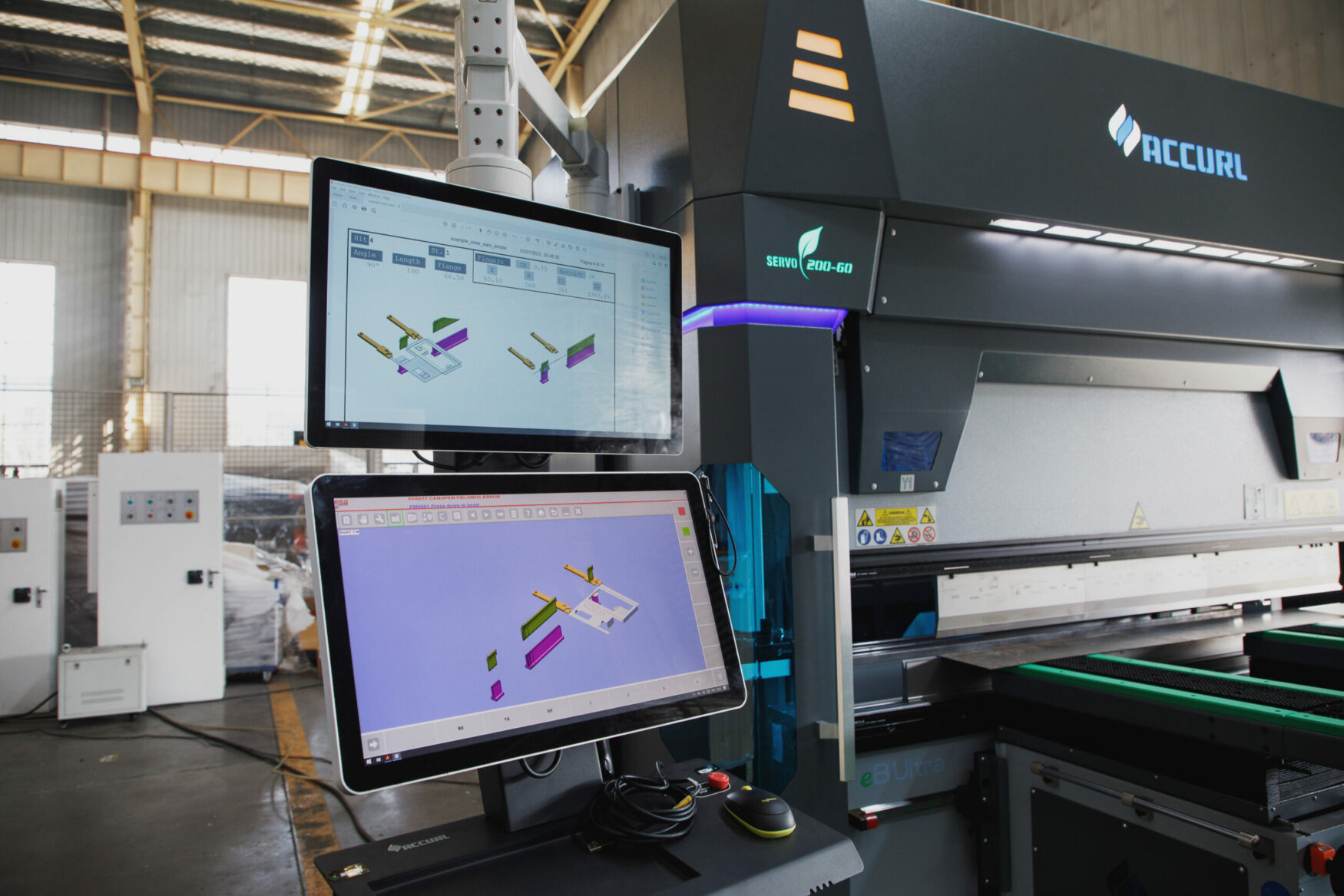

The CNC controller is the computer that allows the operator to easily control the laser. It’s used to set parameters for the material type and thickness, laser cutting axes, and accuracy of the cut itself.

Motion System

The motion system, usually powered by a servo motor, is the part of the machine that allows the laser to move along multiple axes, creating intricate or simple cuts with ease. Not only that, but it also determines the speed of the cut as long as the power of the laser is high enough. With the Accurl SMART GIANT Series, the motor propels up to 100m/min XY speed with unmatched ±0.05mm accuracy.

Cutting Bed

The cutting bed is simply the area where the material is placed for cutting. In large-format laser-cutting machines, this area is large enough to accommodate bigger pieces of metal, wood, or plastic.

The Large Format Laser Cutting Process

After preparing the materials, the laser cutting process follows a few primary steps in order to produce swift, high-quality cuts.

1. Set the Parameters for the Cut

Using the CNC controller, you can set the right parameters for the type of cut as well as the type of material that you will be cutting. With advanced controls over laser power, speed, focal length, and more, you can adapt the cutting process specifically for your operations.

For example, higher speed without higher power can make for engravings while high speed and higher power can boost efficiency while maintaining accurate cuts.

2. Laser Beam Generation and Focusing

The next part of the process is the generation of the laser beam. This is done by the machine when the operator tells it to begin. After that, the laser beam will need to be manipulated into the nozzle and lens, focusing on a smaller area. Depending on the large format laser cutter model, this will be done primarily with the lens as well as the focal length.

Higher-end systems with unparalleled precision can offer laser beam focusing in real-time, allowing for extremely controlled settings that correct the cutting process during operation. This produced less waste and optimal precision and cut quality.

3. Material Interaction and Motion

As soon as the laser is focused on the material, it will start cutting. However, the process has just begun. How long it takes will depend on the type of laser as well as the thickness of the material. The large format laser cutter will follow the parameters the operator set, but the operator will still have to examine the motion to ensure not only safety but a precise cut without issues.

4. Finishing

Once the cut is finalized and the laser powers off, you will need to inspect the material to make sure the cut is accurate and clean. However, always wait an adequate time to allow the material to cool down. It will be extremely hot immediately following the laser-cutting process.

To simplify the loading and offloading process and substantially boost operational efficiency, choose the Accurl SMART GIANT with simultaneous loading/offloading using separate table sections.

Tips for Precision and Efficiency

Here are a few tips to help you maximize precision and efficiency while minimizing material waste with the principles of laser-cutting machines.

- Properly maintain your laser cutter at all times to improve performance while extending lifespan. Check out our laser-cutting machine maintenance tips!

- Invest in a high-quality machine with top-of-the-line optics including lenses and mirrors.

- Fine-tune laser cutting parameters to discover the best programmable settings for your material, cut type, and more.

- Minimize material movement during operation with clamps, jigs, or other built-in or add-on equipment.

- Test, test, test and adjust as needed before committing to certain settings to minimize material waste.

Conclusion

So, is a large format laser cutting machine good for your organization? They are perfect additions to any large-scale operations offering the precision needed for aerospace parts and medical equipment, the efficiency perfect for consumer goods and automotive equipment, and the reliability required by any other industry including signage, construction, and more.

Accurl offers cost-effective machines with unmatched durability, precision, and efficiency. Plus, we offer top-notch support. Click here to contact us for more information about our large-format laser-cutting machines!