Laser-cutting machines are superb machines that can boost efficiency and precision for industrial operations, but they aren’t cheap. However, with proper maintenance, you can generate a high ROI with a longer lifespan and fewer repairs.

That’s why Accurl experts with over 25 years of experience put together this guide so you can follow best practices for laser-cutting machine maintenance. Keep reading to learn about the benefits of proper maintenance like extending the laser cutting machine lifespan and discover tips for cleaning, lubrication, and more.

But first, what are laser-cutting machines and why are they essential to many operations?

Laser Cutting Machines: Boosting Efficiency and Precision for Various Industries

A laser cutting machine uses a high-powered laser to cut through various materials including plastics and metals. This is not only a swift process but can be extremely precise without compromising the integrity of the material.

The best options like the Accurl Fiber Laser Cutting High Power ML Plus are used in various industries from fabricating medical equipment to improving efficiency for aerospace, automotive, and consumer goods manufacturers.

Since they can cost anywhere from $5,000 to $150,000+ you probably want to know how they last as well. A good machine from a reputable vendor like Accurl should last at least 10 years of regular use or 15,000 hours of cutting, but with proper maintenance, they can last even longer. That’s not the only benefit of proper maintenance though.

Benefits of Laser Cutting Machine Maintenace

There are several reasons to follow best maintenance practices for laser cutters like boosting performance, prolonging laser cutting equipment life, improving safety, and reducing repair costs.

Extend Lifespan

Extending the laser cutting machine lifespan is important and maintenance is the best way to do that. With proper cleaning, lubrication, and maintenance, you can keep the machine running smoothly with less risk of damage or strain.

Boost Performance

Laser-cutting maintenance tips will ensure your machine is running at peak performance with the best efficiency, precision, cutting speeds, and operation. That means better results and lower costs for your business.

Improve Safety

A run-down or damaged laser-cutting machine is a major safety hazard, putting your workers at risk. Maintaining will prevent accidents and injuries while elevating your efficiency and performance.

Reduce Repair Costs

Laser-cutting machine repairs can be expensive, negatively impacting your business’ profitability. However, keeping it properly maintained will mean your machine requires fewer repairs, less often.

Laser Cutter Maintenace Tips

There are a few specific things you must do to properly maintain your powerful laser cutting machine including proper cleaning of lenses, mirrors, and nozzles, replacing worn partners, checking alignment, keeping it properly lubricated, and more.

Lubrication

Lubrication is one of the most important maintenance steps. That’s because proper lubrication ensures a smooth operation and reduces wear on moving parts. An unlubricated laser cutting machine can quickly damage itself and may not be as efficient or precise as a well-oiled machine.

To lubricate, you should follow the manufacturer’s instructions. However, this normally involves turning the power completely off, cleaning the guide rail, and applying the proper lubricant to the guide rail before running the machine to lubricate all areas. turn the power completely off and clean the guide rail with

Cleaning Mirrors and Lens

You should clean the mirrors and laser lens often. The optic mirrors and lenses can become dirty from dust, debris, moisture, smoke, and other contaminants. This can change the laser reflection rate, potentially damaging other components.

Remove the laser head, divide the components, and use a soft swab to clean both sides of the lens carefully and methodically. If necessary, you can use warm water or a cleaner designed for this purpose. Then, remove any residue with a dry, scratch-resistant cloth.

Cleaning Other Components

In addition to the mirrors and lens, you also need to clean the exhaust fan, tube filter, and nozzles. All of these parts can become quite dirty after use and could become a potential safety hazard to your machine or operator.

To clean the fan, remove the cover and wipe all dust from the blades with a brush or compressed air. To clean the tube filter, remove it and then use a low-pressure vacuum cleaner. Wipe down nozzles daily to ensure precise cutting.

Replacing Worn Parts

Make sure you check all laser-cutting machine parts regularly. Then, if they are worn out they should be replaced as soon as possible. This is not only good for prolonging laser cutting equipment life, but also for optimal performance.

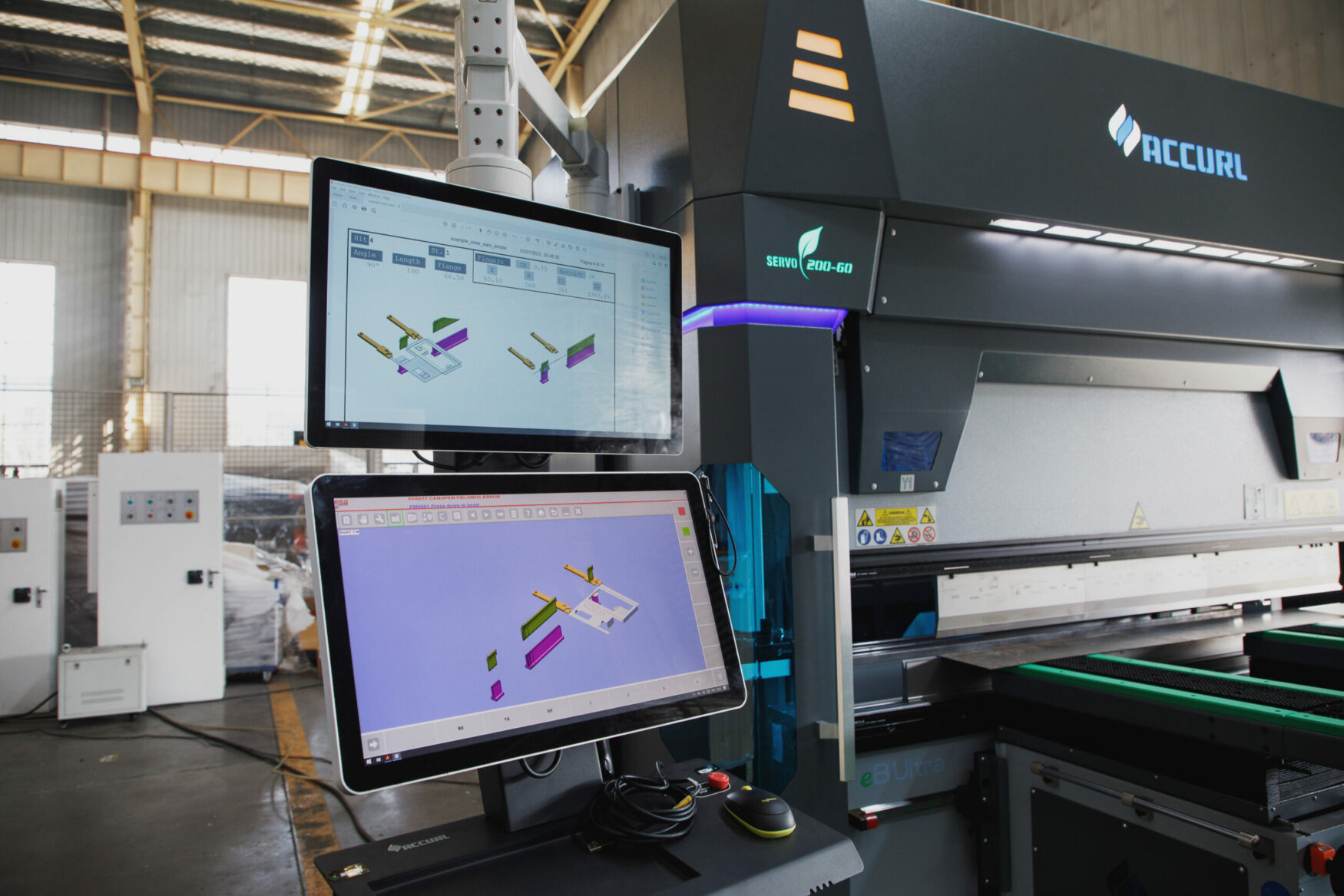

While checking parts, you should also make sure the software doesn’t need an update if you’re using a computer-controlled Laser Cutting Machine like the powerful, easy-to-use, and extremely precise Accurl Fiber Laser Cutting Machine. Finally, you should check alignment during this process. To help you out, here’s a Laser Cutting Machine maintenance and inspection checklist.

Laser Cutting Machine Inspection Checklist

While you should check systems and visually inspect your machine before every use, the most important maintenance steps can be completed once per week or once per month. Set a clear schedule for you and your employees to perform these checks to make it routine and ensure proper maintenance is completed before damage to your machine.

Weekly Maintenance Checklist

These tasks should be completed every week or every 10-40 hours of use.

- Clean Mirror and Lens

- Lubricate

- Clean Machine Bed

- Clean Nozzles

- Check Water Level

- Remove Visible Debris

- Check for Software Updates

Monthly Maintenance Checklist

These maintenance practices for laser cutters should be completed approximately once every 30 days to ensure optimal performance and safety.

- Clean Exhaust Fan

- Clean Tube Filter

- Inspect All Moving or Friction Parts

- Examine and Adjust Alignment

- Replace Parts As Needed

Conclusion

Now that you know how to properly maintain your laser cutting machine, it will last longer and be safer, more precise, and more efficient. Just make sure you perform proper weekly and monthly maintenance so you don’t risk damage.

Want a top-quality laser cutting machine designed for long-lasting performance? Click here to learn about the Accurl Fiber Laser Cutting High Power ML Plus